White-light fluorescent powder as well as preparation method and application thereof

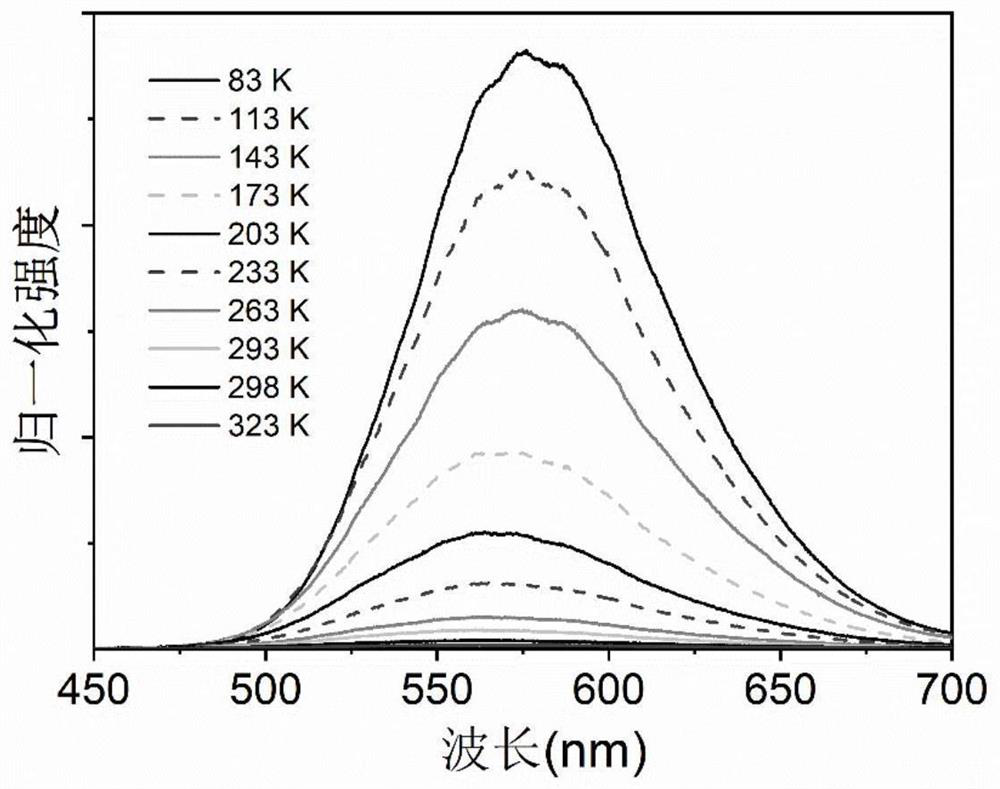

A phosphor, white light technology, applied in chemical instruments and methods, luminescent materials, climate sustainability, etc., can solve the problems of low color rendering index, high color temperature, complex process flow, etc., and achieve simple preparation process and thermal stability. Good, luminous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

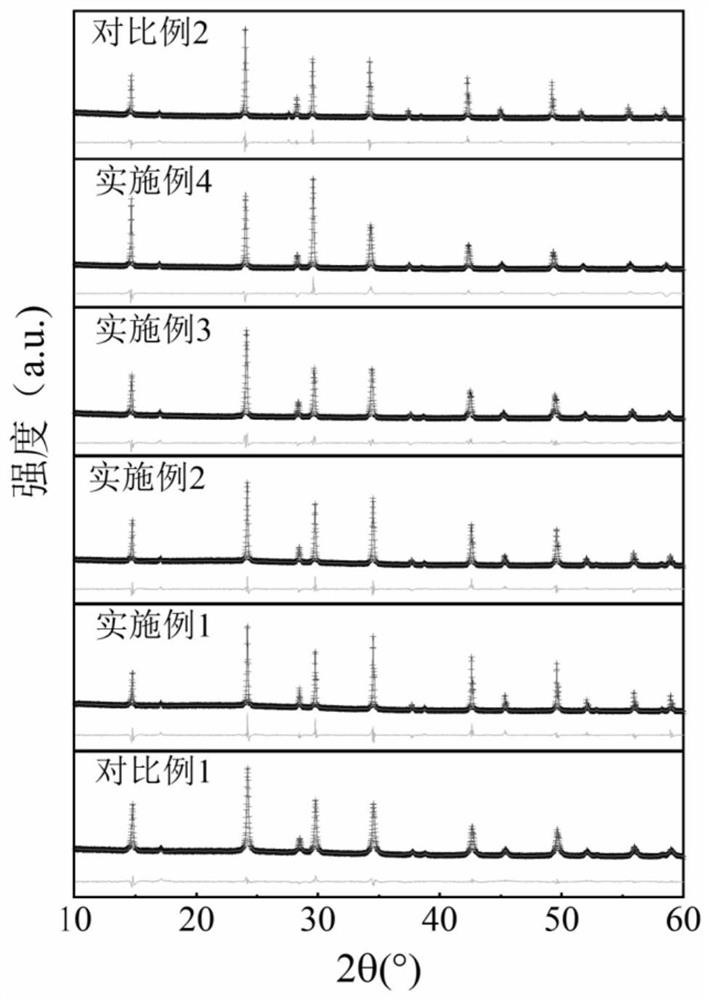

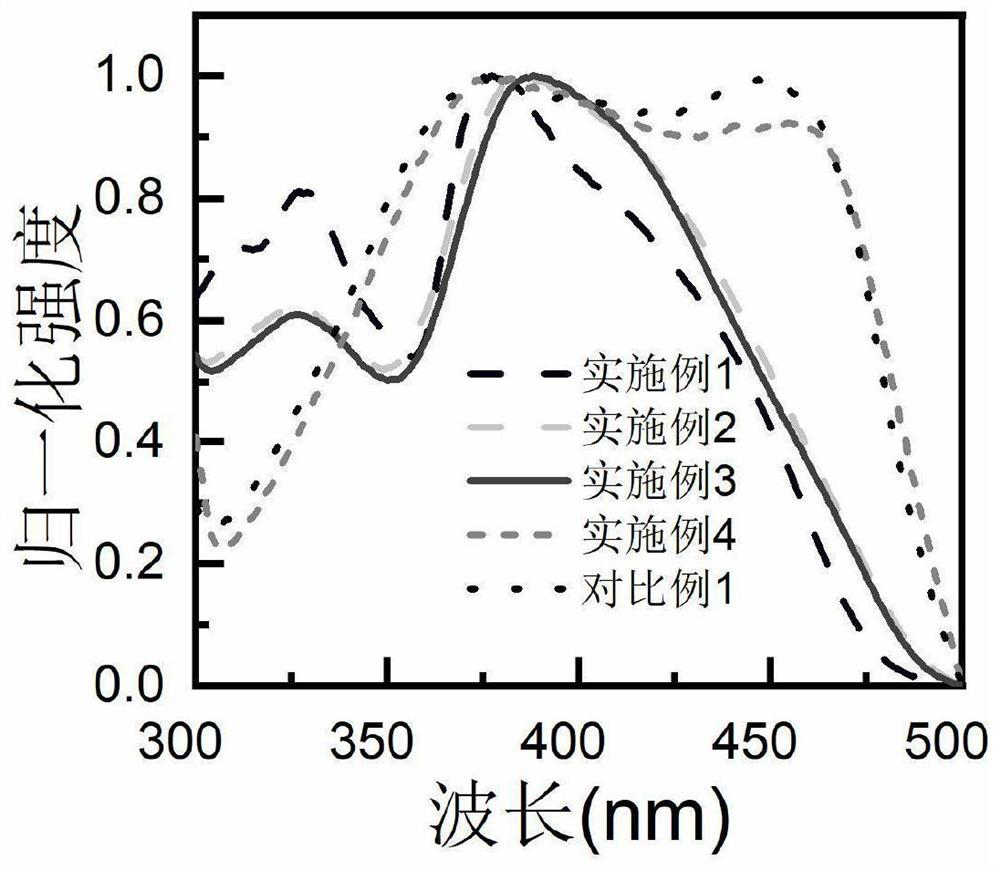

Embodiment 1

[0054]a) Clean the PTFE liner with deionized water for 10 minutes, clean the PTFE liner with acetone for 10 minutes, clean the PTFE liner with isopropanol for 10 minutes, and clean the PTFE liner with deionized water 10min, then blow dry with a nitrogen gun.

[0055] b) Weigh 336.72mg CsCl, 234.9mg SnCl 4 , 27.0 mg TeCl 4 Mix and place in the cleaned polytetrafluoroethylene liner, add 4ml of hydrochloric acid (the mass percent concentration of hydrochloric acid can be 37%), and assemble the hydrothermal kettle.

[0056] c) The hydrothermal kettle was placed in a muffle furnace, and the temperature of the muffle furnace was set at 30°C and raised to 180°C over 2 hours, kept for 10 hours, and then slowly lowered to room temperature at a cooling rate of 10°C / h.

[0057] d) Take out the hydrothermal kettle in the muffle furnace, pour off the hydrochloric acid in the liner, take out the crystals, and get Cs after grinding 2 sn 0.9 Te 0.1 Cl 6 White phosphor.

Embodiment 2

[0059] a) Clean the PTFE liner with deionized water for 10 minutes, clean the PTFE liner with acetone for 10 minutes, clean the PTFE liner with isopropanol for 10 minutes, and clean the PTFE liner with deionized water 10min, then blow dry with a nitrogen gun.

[0060] b) Weigh 336.72mg CsCl, 156.3mg SnCl 4 , 107.8 mg TeCl 4 Mix and place in the cleaned polytetrafluoroethylene liner, add 4ml of hydrochloric acid (the mass percent concentration of hydrochloric acid can be 37%), and assemble the hydrothermal kettle.

[0061] c) The hydrothermal kettle was placed in a muffle furnace, and the temperature of the muffle furnace was set at 30°C and raised to 180°C over 2 hours, kept for 10 hours, and then slowly lowered to room temperature at a cooling rate of 10°C / h.

[0062] d) Take out the hydrothermal kettle in the muffle furnace, pour off the hydrochloric acid in the liner, take out the crystals, and get Cs after grinding 2 sn 0.6 Te 0.4 Cl 6 White phosphor.

Embodiment 3

[0064] a) Clean the PTFE liner with deionized water for 10 minutes, clean the PTFE liner with acetone for 10 minutes, clean the PTFE liner with isopropanol for 10 minutes, and clean the PTFE liner with deionized water 10min, then blow dry with a nitrogen gun.

[0065] b) Weigh 336.72mg CsCl, 78.3mg SnCl 4 , 189.0 mg TeCl 4 Mix and place in the cleaned polytetrafluoroethylene liner, add 4ml of hydrochloric acid (the mass percent concentration of hydrochloric acid can be 37%), and assemble the hydrothermal kettle.

[0066] c) The hydrothermal kettle was placed in a muffle furnace, and the temperature of the muffle furnace was set at 30°C and raised to 180°C over 2 hours, kept for 10 hours, and then slowly lowered to room temperature at a cooling rate of 10°C / h.

[0067] d) Take out the hydrothermal kettle in the muffle furnace, pour off the hydrochloric acid in the liner, take out the crystals, and get Cs after grinding 2 sn 0.3 Te 0.7 Cl 6 White phosphor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com