Tobacco extract, preparation method thereof and novel tobacco product

A technology of tobacco extract and tobacco, applied in the field of tobacco, can solve problems such as increasing the content of aroma substances, and achieve the effects of short time-consuming, labor-saving and high-efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

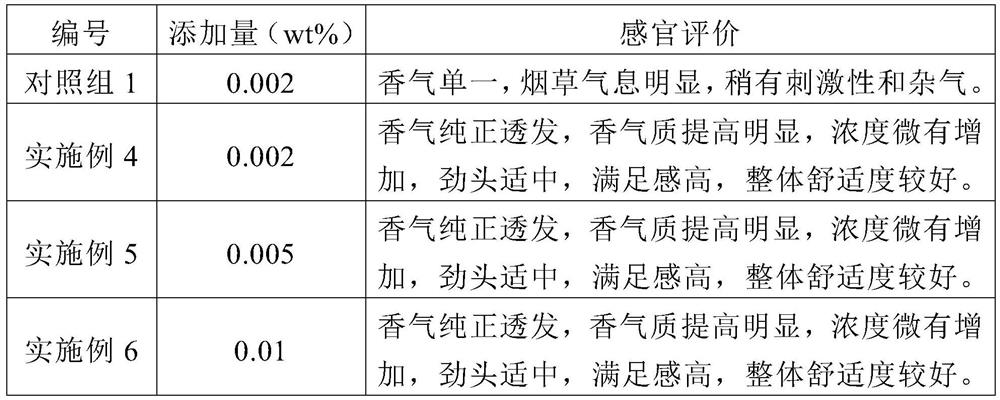

Examples

Embodiment 1

[0034] This embodiment discloses a method for preparing tobacco extract from flue-cured tobacco raw materials in Yuxi, Yunnan. The specific steps are as follows:

[0035] (1) After pulverizing the raw material with a mass of m, pass through a 40-mesh sieve and mix it with water with a mass of 1.5 m; respectively add cellulase (enzyme activity: 200,000 U) and 0.5% m α-amylase (enzyme activity: 2000 U) and 0.3% m pectinase (enzyme activity: 30,000 U), after uniform stirring, react at 50° C. for 3 hours.

[0036] (2) add ammoniacal liquor (concentrated to 28%) in the tobacco mixture that step (1) obtains, until the pH value is 7.0; , reacted at 50°C for 1h.

[0037] (3) Mix the tobacco mixture obtained in step (2) with an 8m ethanol solution (95%, v / v), extract at 55°C for 1 hour; separate the solid and liquid after extraction, and filter the liquid to obtain a tobacco extract.

[0038] (4) Concentrate the tobacco extract under reduced pressure to a solid content of 40% at 65°C...

Embodiment 2

[0041] This embodiment discloses a method for preparing a tobacco extract using burley tobacco as a raw material, and the specific steps are as follows:

[0042] (1) After pulverizing the raw material with a mass of m, pass through a 60-mesh sieve, and mix it with water with a mass of 2 m; respectively add cellulase (enzyme activity: 200,000 U) with a mass of 0.5% m and 0.5% m α - Amylase (enzyme activity: 2000 U) and 0.5% m pectinase (enzyme activity: 30,000 U), after uniform stirring, react at 50° C. for 2 hours.

[0043] (2) add ammoniacal liquor (concentrated to 28%) in the tobacco mixture that step (1) obtains, until the pH value is 7.0; , Reacted at 50°C for 1.5h.

[0044](3) Mix the tobacco mixture obtained in step (2) with a mass of 10m ethanol solution (90%, v / v), extract at 60° C. for 1 hour; separate solid and liquid after extraction, and filter the liquid to obtain tobacco extract.

[0045] (4) Concentrate the tobacco extract under reduced pressure to a solid con...

Embodiment 3

[0048] This embodiment discloses a method for preparing a tobacco extract using burley tobacco as a raw material, and the specific steps are as follows:

[0049] (1) After pulverizing the raw material with a mass of m, pass it through a 40-mesh sieve, and mix it with water with a mass of 2.5 m; respectively add cellulase (enzyme activity: 200,000 U) with a mass of 0.45% m α-amylase (enzyme activity: 2000 U) and 0.25% m pectinase (enzyme activity: 30,000 U) were stirred uniformly and reacted at 55° C. for 2.5 hours.

[0050] (2) add ammoniacal liquor (concentrated to 27%) in the tobacco mixture that step (1) obtains, until the pH value is 7.2; , Reacted at 50°C for 1.5h.

[0051] (3) Mix the tobacco mixture obtained in step (2) with a mass of 10m ethanol solution (95%, v / v), extract at 65° C. for 1 hour; separate the solid and liquid after extraction, and filter the liquid to obtain a tobacco extract.

[0052] (4) Concentrate the tobacco extract under reduced pressure to a so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com