Preparation method for low-protein tobacco extract for novel tobacco and application

A tobacco extract and low-protein technology, which is applied in the field of preparation of low-protein tobacco extract, can solve the problems of low relative content of aroma components, failure to meet the needs of the tobacco industry, and general quality of tobacco paste, etc., to achieve clear characteristic aroma and improve Acceptable level, good aroma effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Take 500g of pulverized Burley tobacco leaves, add 2000mL of 75% ethanol and heat at 80°C for 3h to extract. After filtering, the filtrate is concentrated to remove the solvent. After concentration, the Burley tobacco concentrate is obtained. After adjusting the pH value to 7.0 with sodium hydroxide, add 5.0g / L neutral protease to it and incubate in a water bath at 40°C for 4h, and concentrate to prepare a neutral protease enzymatically hydrolyzed Burley tobacco extract.

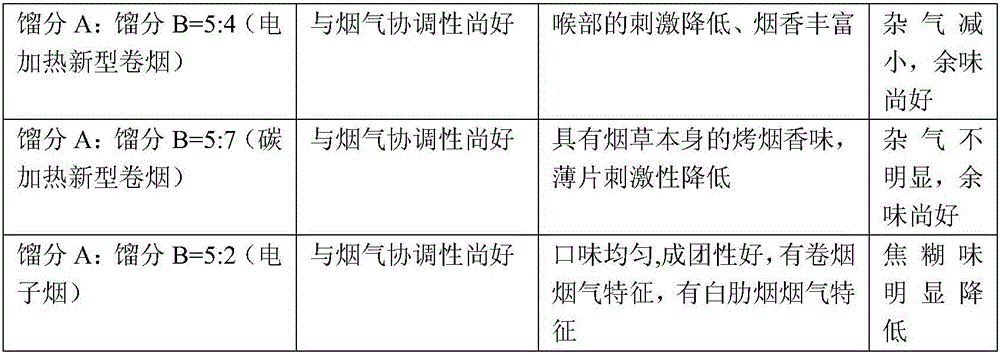

[0017] Take the burley tobacco extract and place it in a vacuum distillation equipment. The concentrate is distilled under reduced pressure. The system pressure is 1mmHg. The fraction A below 200°C and the fraction B between 200°C and 300°C are collected. Take 1g of the distillate whose mass ratio is fraction A: fraction B=5:4, dissolve it with 6g propylene glycol, and add it to the electric heating new-type cigarette tobacco products prepared by thin slices, which can reduce the irritation to the throat ...

Embodiment 2

[0019] Take 500g of crushed flue-cured tobacco leaves, add 4000mL of 60% ethanol and heat at 85°C for 4h to extract. After filtering, the filtrate is concentrated to remove the solvent. After concentration, the flue-cured tobacco concentrate is obtained. The flue-cured tobacco extract is adjusted with sodium hydroxide to adjust the pH After the value is 7.0, add 5.0g / L neutral protease to it and incubate in a water bath at 55°C for 4h, and concentrate the flue-cured tobacco extract after enzymolysis with neutral protease.

[0020] Take the flue-cured tobacco extract, place it in a vacuum distillation device, and distill the concentrate under reduced pressure, slowly heating, and the system pressure is 3mmHg, and collect fraction A below 200°C and fraction B at 200°C to 300°C. Take 1 g of the distillate whose mass ratio is fraction A: fraction B=5:7, dissolve it with 7 g of propylene glycol, and add it to the new carbon-heated cigarette tobacco product prepared by the sheet.

Embodiment 3

[0022] Take 500g of pulverized Burley tobacco leaves, add 3000mL of 95% ethanol and heat reflux for 3h at 65°C for extraction. After filtration, the filtrate is concentrated to remove the solvent. After concentration, the Burley tobacco concentrate is obtained. After adjusting the pH value of 7.0 with sodium hydroxide, 5.0g / L neutral protease was added to it and bathed in a water bath at 50°C for 3h, and concentrated to prepare a neutral protease enzymatically hydrolyzed Burley tobacco extract.

[0023] Take the burley tobacco extract and place it in a vacuum distillation equipment. The concentrate is distilled under reduced pressure. The system pressure is 5mmHg. The fraction A below 200°C and the fraction B between 200°C and 300°C are collected. Take 1g of the distillate whose mass ratio is fraction A: fraction B=5:2, dissolve it with 8g propylene glycol, and add it to the electronic cigarette.

[0024] After adding the low-protein tobacco extracts prepared in the foregoing Examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com