Nail polish glue and preparation method thereof

A nail polish, No. 1 technology, applied in the field of nail polish and its preparation, can solve the problems of nail polish penetration, paronychia, nail yellowing, etc., to achieve full and clear color, long-lasting gloss, easy to apply convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

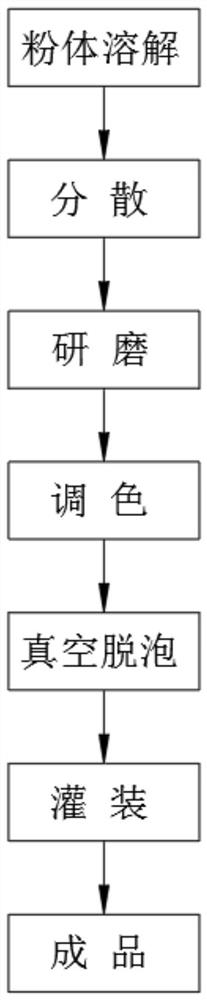

[0031] Embodiment one, with reference to Figure 1-2 , a kind of nail polish, by mass percentage, including the following components: No. 1 resin 22%, No. 2 resin 25%, monomer 36%, fumed silicon dioxide 3%, leveling agent 1%, dispersant 3% , color paste 8%, photoinitiator 2%;

[0032] The preparation method of nail polish, comprises the following steps:

[0033] S1, powder dissolution

[0034] Take the monomer, dispersant, and initiator respectively, weigh them out according to the ratio in the formula, and put them into the mixing bucket, start the dispersion plate to stir at a speed of 600 rpm, and slowly add fumed silica while stirring Stir, after fully blending, adjust the rotation speed to 1200 rpm, stir for 25 minutes, stir until it dissolves evenly, and prepare the mixed solution A;

[0035] S2. Scatter

[0036] Take No. 1 resin, No. 2 resin, fumed silicon dioxide, and advection agent, weigh them out according to the ratio in the formula, add them to the mixing tank...

Embodiment 2

[0046] Embodiment two, refer to figure 2 , Sartomer CN964 is used for No. 1 resin, Sartomer CN998 is used for No. 2 resin, Mitsubishi HEMA is used for monomer, R974 is used for fumed silicon dioxide, BYK-333 of Germany is used for advection agent, BYK-346 of Germany is used for dispersant, and color paste Merck is selected, BASF 75980-60-8 is selected as the photoinitiator, and fumed silicon dioxide not only promotes and maintains the flowability and anti-caking performance of the raw material powder during the processing of nail polish, but also improves the stability of nail polish , and enhance the anti-corrosion effect, the dispersant improves the flow and leveling, prevents surface defects, and the monomer has a photocuring effect, which accelerates the curing of the nail polish after use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com