A kind of PP material injection molding process and its prepared bottle cap

A process and raw material technology, applied in the field of PP material injection molding process and bottle caps prepared, can solve the adverse effects of tensile properties of PP plastic products, impaired compatibility between PP materials and nucleating agents, and inconvenient enhancement of nucleating agents It can improve the mechanical properties of the product, shorten the crystallization cycle, and improve the viscosity of the product.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

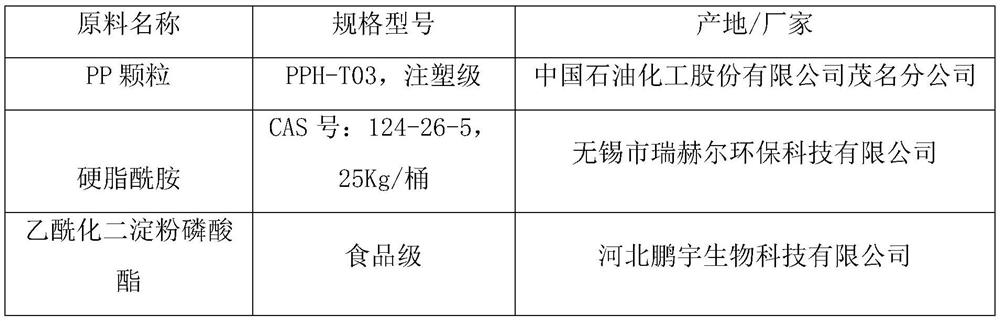

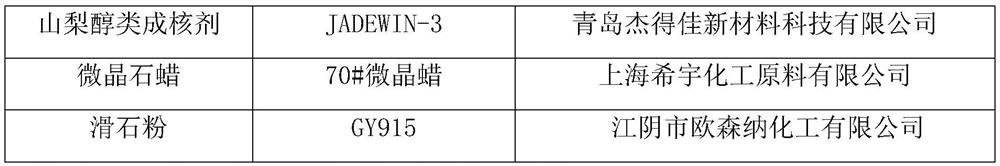

Method used

Image

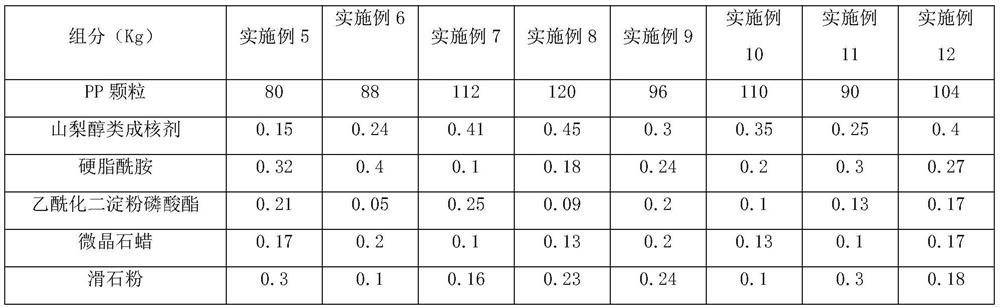

Examples

Embodiment 1

[0038] Embodiment 1: a kind of PP material injection molding process, comprises the steps:

[0039] Preparation of S1 admixture: Weigh 0.15Kg of acetylated distarch phosphate, add 0.3Kg of sorbitol nucleating agent, 0.25Kg of stearamide and 0.15Kg of microcrystalline paraffin, mix well, heat to 50°C for pretreatment for 3min, reduce After reaching room temperature, the admixture was prepared, and the admixture was pulverized with a pulverizer, and sieved with a sieve with an aperture of 50 μm. Granules to make admixtures.

[0040] S2 Mixing: Weigh 100Kg of PP granules, add the admixture prepared in step S1, and mix evenly to obtain powder.

[0041] S3 melting: the powder obtained in step S2 is heated to 195° C. to obtain a molten liquid.

[0042] S4 injection molding: heat several standard 3025 mineral water bottle cap molds to 80 °C, inject the melt into the 80 °C 3025 mineral water bottle cap mold with an injection molding machine at a pressure of 110 bar, and keep the pre...

Embodiment 2

[0046] The difference between Example 2 and Example 1 is that Example 2 does not add talc, and the others are consistent with Example 1.

Embodiment 3

[0048] The difference between Example 3 and Example 1 is that the admixture of Example 3 is not subjected to the heating pretreatment process, and Example 3 weighs 0.15Kg of acetylated distarch phosphate, adds 0.3Kg of sorbitol nucleating agent, 0.25Kg Stearamide and 0.15Kg of microcrystalline paraffin were mixed uniformly to prepare an admixture, and the others were consistent with Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com