Integrated deep-sea mining vehicle

A deep-sea mining and integrated technology, applied in mining minerals, special mining, earth square drilling, etc., can solve the problems of low economy and reliability, increasing the difficulty and cost of system deployment and recovery, and high requirements for cooperation between mining workshops. Achieve effects that are conducive to regeneration, reduce the impact on the marine environment, and ensure continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

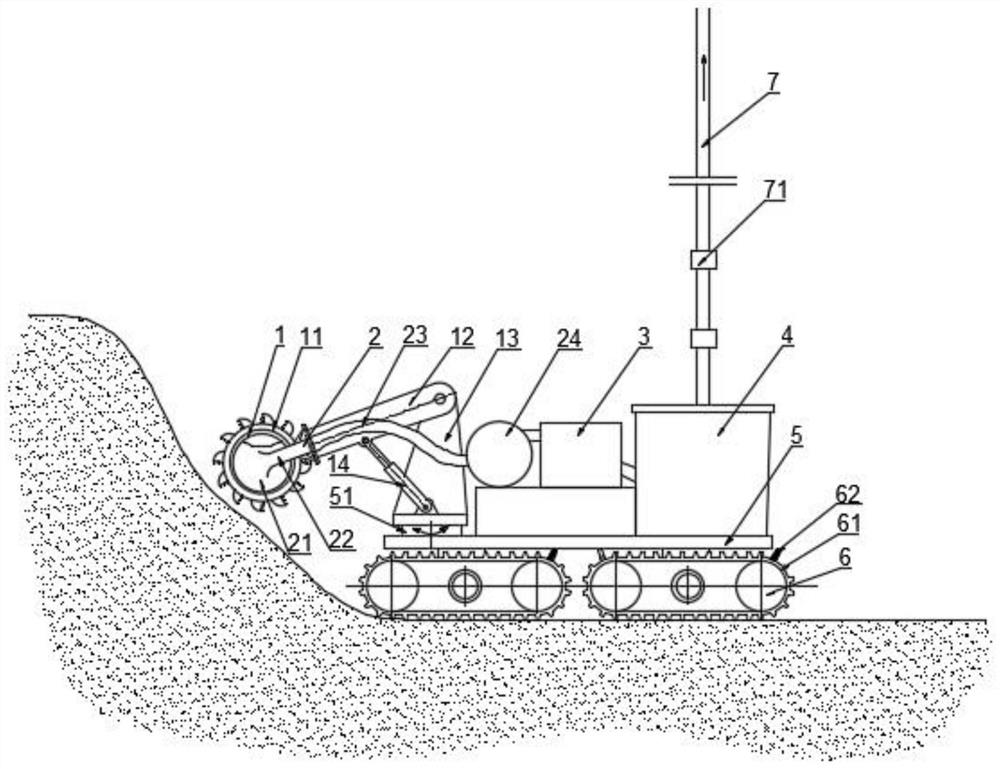

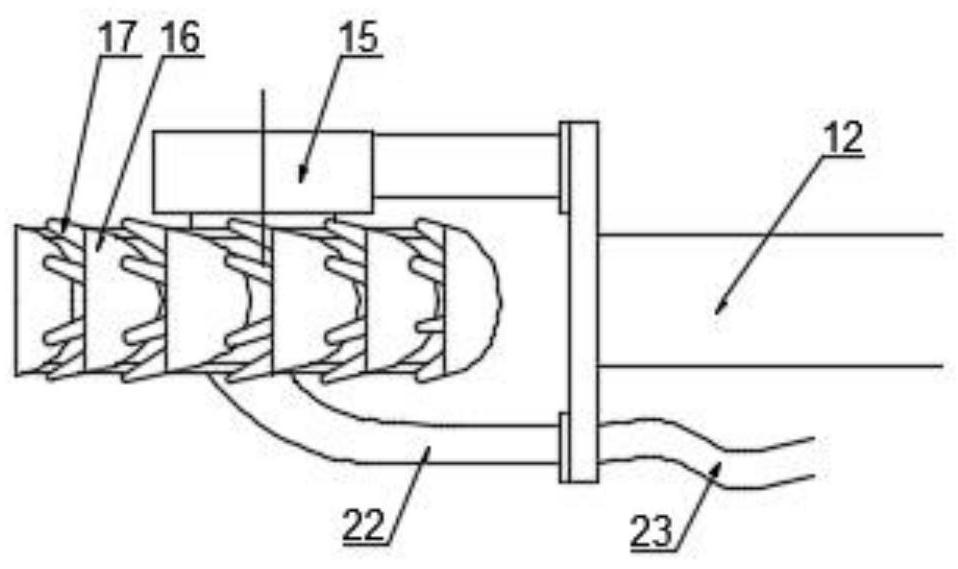

[0025] Such as figure 1 As shown, the integrated deep-sea mining vehicle of this embodiment adopts a four-crawler-type traveling mechanism 6, and the power is provided by cables lowered by a sea surface support ship. A stepped frame 5 is installed on the traveling mechanism 6 to support the cutting device 1 , the collecting device 2 , the hydrocyclone 3 , the feed bin 4 , the lifting device 7 and other equipment. A turntable 51 is arranged at the front end of the vehicle frame 5, and the turntable 51 is powered by a hydraulic motor. Described cutting device 1 comprises wheel-shaped cutting head 11, boom 12, support 13 and hydraulic cylinder 14, and described cutting head 11 is installed on an end of boom 12, and the other end of described boom 12 is connected with support. The top of 13 is hinged, and described support 13 is installed on the turntable 51, and the piston rod of described hydraulic cylinder 14 links to each other with the middle part of boom 12, and cylinder ba...

Embodiment 2

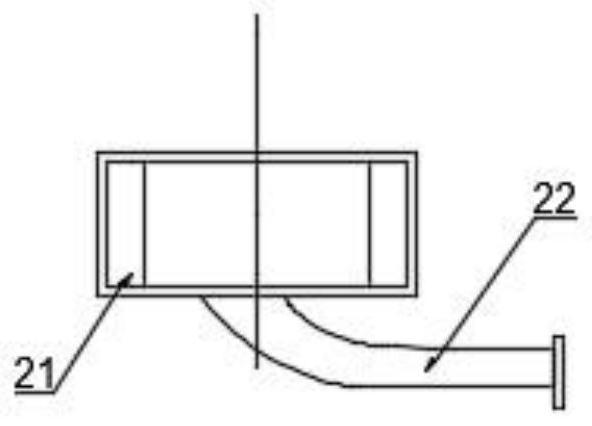

[0031] Compared with embodiment 1, the difference of this embodiment is: as Figure 4As shown, the bottom of the ore suction chamber 21 is provided with a material receiving plate 27 that slides up and down with the ore suction chamber 21, and the material receiving plate 27 is connected to the bottom of the ore suction chamber through a telescopic structure. Specifically, the telescopic structure includes a rod body 28 and a pipe body 29 that are sealed and slidingly socketed. The top of the rod body 28 is connected to the receiving plate 27, and the bottom is connected to the inner wall of the pipe body 29 through a spring 210. The enclosed space can avoid spring corrosion. . The pipe body 29 is connected to the bottom of the ore suction chamber 21 . When a blockage is formed due to phenomena such as bridge arches, because the bucket 16 continuously pours mineral materials into the ore suction chamber 21, the mineral material carried on the material receiving plate 27 will ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com