Strain pickup magnetic adsorption optical cable

A magnetic adsorption and optical cable technology, applied in the direction of light guides, optics, optical components, etc., can solve problems such as low coupling efficiency, large loss of seismic wave signals, and reduced optical fiber sensitivity, so as to improve response ability, improve pickup ability, and reduce energy loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

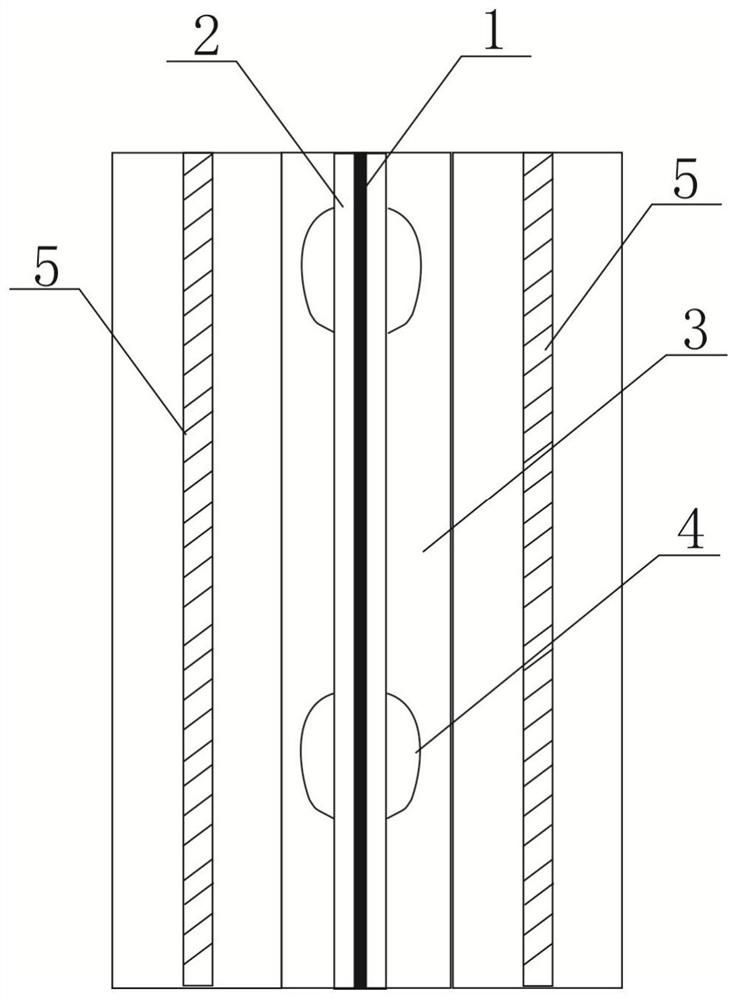

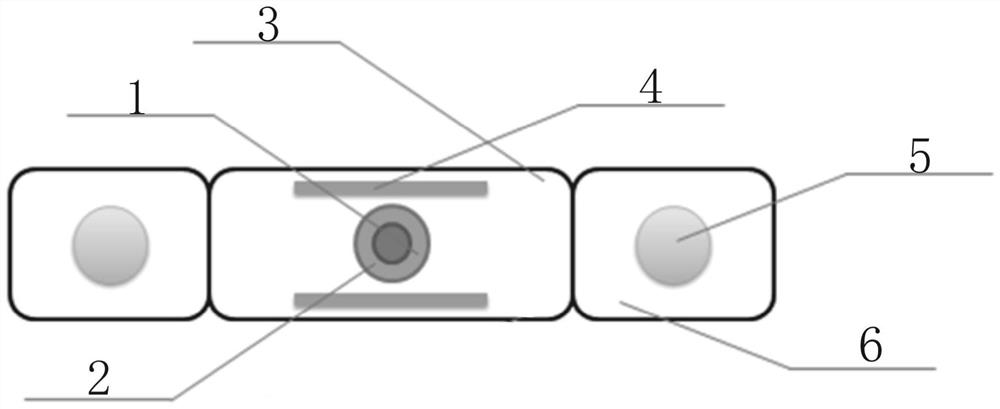

[0026] Embodiment 1, reference figure 1 with figure 2 , a strain-picking magnetic adsorption optical cable of this solution, including a tight-packed optical fiber 1 , an optical fiber outer sheath 2 , a protective layer 3 , an adsorption element 4 and a strengthening unit 6 .

[0027] Among them, the outer surface of the tight-packed optical fiber 1 is closely attached to the outer sheath 2 of the optical fiber; the type of optical fiber in the tight-packed optical fiber 1 is a single-mode optical fiber, and the number of optical fibers is at least one; the sleeve of the tight-sleeved optical fiber is made of a polymer material , You can choose polyvinyl chloride, low-smoke halogen-free polyolefin, nylon, elastomer and other materials.

[0028] The type of fiber in the tight tube fiber is single-mode fiber, the number of fiber is 1, the type of fiber is ordinary communication fiber, and the type of fiber can also choose grating array fiber.

[0029] The outer diameter of t...

Embodiment 2

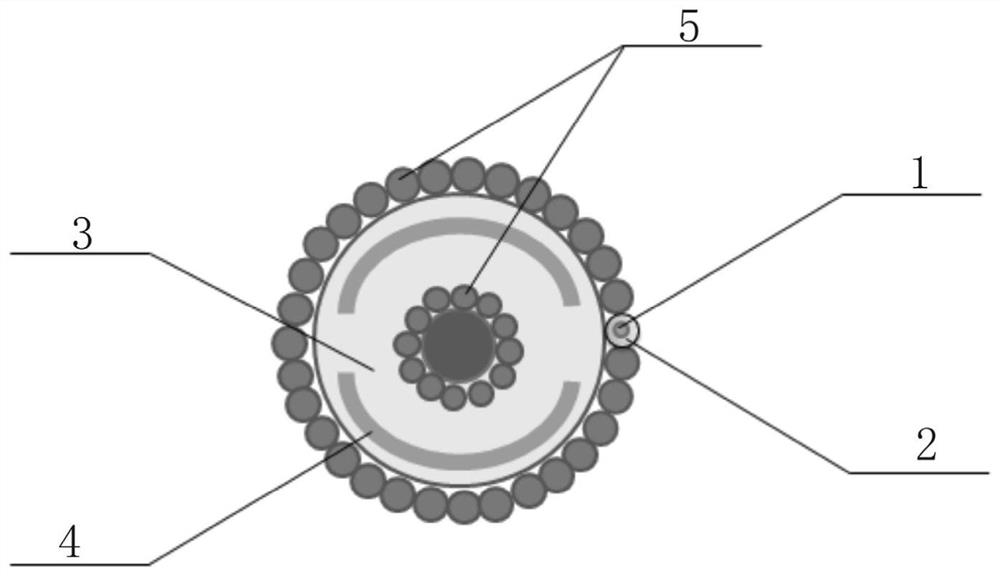

[0036] Embodiment 2, refer to image 3 , a kind of strain pick-up magnetic absorption optical cable of this scheme, comprises tight-wrapped optical fiber 1, optical fiber outer sheath 2, protective layer 3, adsorption element 4 and reinforcing core 5; 2.

[0037] Among them, several reinforcing cores 5 are closely arranged along the outside of the outer sheath 2 of the optical fiber, which are used to improve the structural strength of the tightly wrapped optical fiber and the outer sheath of the optical fiber, wherein the adsorption units 4 are arranged in the protective layer at certain intervals, and the protective layer Several reinforcing cores are set outside; among them, one of the reinforcing cores can preferably be replaced by a tight-packed optical fiber, wherein the structure of the tight-packed optical fiber is that a bare optical fiber is arranged in a capillary steel pipe, and in this structure, several reinforced cores arranged outside the protective layer One ...

Embodiment 3

[0042] Embodiment 3, refer to Figure 4 , 5 , a strain-picking magnetic adsorption optical cable of this solution, including a tight-packed optical fiber 1 , an optical fiber outer sheath 2 , a protective layer 3 , an adsorption element 4 and a reinforcing core 5 .

[0043]A groove 7 is arranged on one side of the protective layer 3, and the tightly wrapped optical fiber 1 and the outer sheath 2 of the optical fiber are arranged in the groove 7, and the groove 7 can be rectangular, circular or elliptical. The advantage of this structure setting is that on the basis of the existing optical cable structure, different optical cable types and performances can be realized by replacing the tight-wrapped optical fiber 1 and the optical fiber outer sheath 2, which improves the application ability of the optical cable in different terrains and different well conditions.

[0044] The adsorption element 4 is arranged in the protective layer 3, and the adsorption element 4 is distributed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com