A real-time monitoring system for linear motor with double loop network

A linear motor and real-time monitoring technology, applied in general control systems, control/regulation systems, propulsion systems, etc., can solve the problems of large influence of motor performance parameters, high requirements for real-time monitoring, and high requirements for monitoring reliability, and achieve anti-electromagnetic The effect of strong interference ability, small size and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

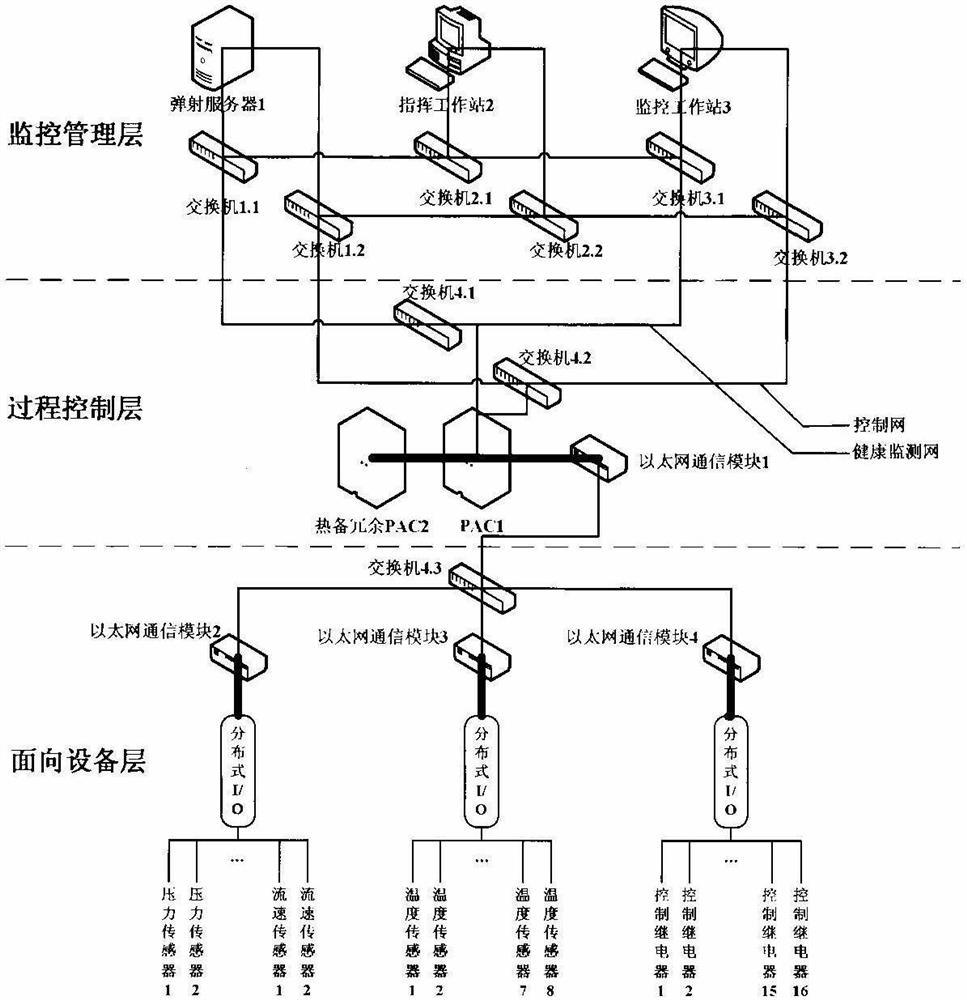

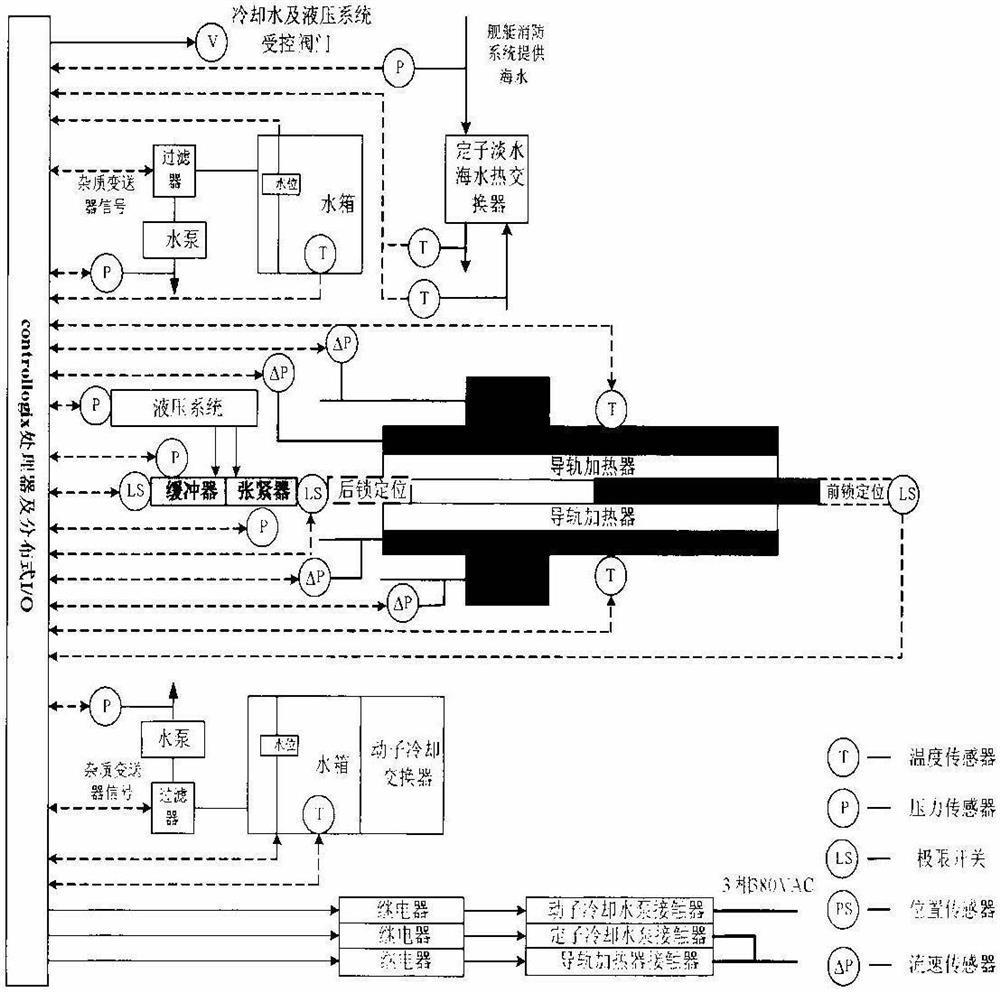

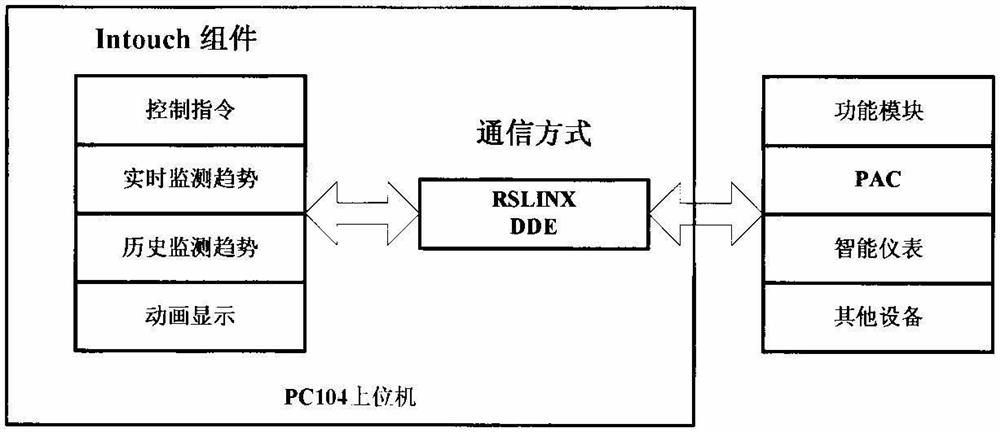

[0027] exist figure 1 Among them, the linear motor real-time monitoring system is mainly divided into three layers: monitoring management layer, process control layer, and device-oriented layer. The diagram is now explained according to the signal flow direction of the monitoring data from the bottom layer to the top layer. The sensor network facing the equipment layer collects the monitoring data of the linear motor, such as the stator temperature of the linear motor, the temperature of the mover, the flow rate of the water cooling system of the linear motor, and other analog quantities. The sensor outputs a current of 4 to 20 mA and inputs it to the distributed I / O. In the analog input module 1794-IB16D or the temperature input module 1794-IR8, the switching value such as the limit position switch of the linear motor is converted into a switching lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com