Process improving marine ooze to be used for planting soil

A silt and marine phase technology is applied in the technical field of improving marine silt for planting soil, and achieves the effects of low cost and simple composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

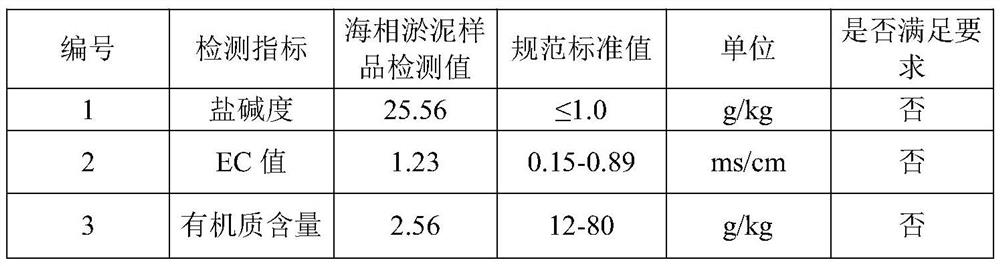

Embodiment 1

[0062] The original incoming marine silt is used as the base material, and its mass fraction is 1 part; the mass fractions of other components relative to the marine silt are: 0.5 part of rice husk (and / or straw), 5 parts of sand, and 0.5 part of biochar parts, 8 parts of organic fertilizer, 0.1 part of desulfurization gypsum; Based on above-mentioned compound formula, the steps of using this formula to process marine silt are as follows: s1: reduce the water content of marine silt to 50%; s2: use rotary tiller to The silt is deeply plowed, the soil ploughing depth is greater than 0.5m, and the rotary tillage is carried out 3 times; s3: add rice husk (and / or straw), sand, and desulfurization gypsum. The rice husk (and / or straw), sand, and desulfurized gypsum are formulated into an improved mixture, and the mixture is divided into three equal parts. Before each rotary tillage, an improved mixture is evenly spread on the soil surface. Shell (and / or straw), sand, desulfurized gyp...

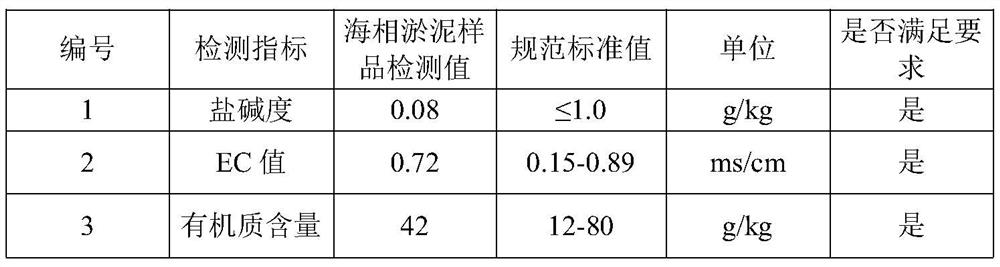

Embodiment 2

[0068] The original incoming marine silt is the base material, and its mass fraction is 1 part; the mass fractions of other components relative to the marine silt are: 3 parts of rice husks (and / or straws), 5 parts of sand, and 0.5 parts of biochar parts, 8 parts of organic fertilizer, 0.5 part of desulfurization gypsum; according to the same steps of processing marine silt as in Example 1, after 28 days of soil conservation, the measured indexes are shown in Table 3. The increase of rice husk (and / or straw) content increases the water permeability, air permeability and organic matter content of marine silt. Compared with the data in Table 3, the salinity and alkalinity of the improved marine silt decreased by 25.50, the EC value decreased by 0.56, and the organic matter content increased by 61.44.

[0069] table 3

[0070]

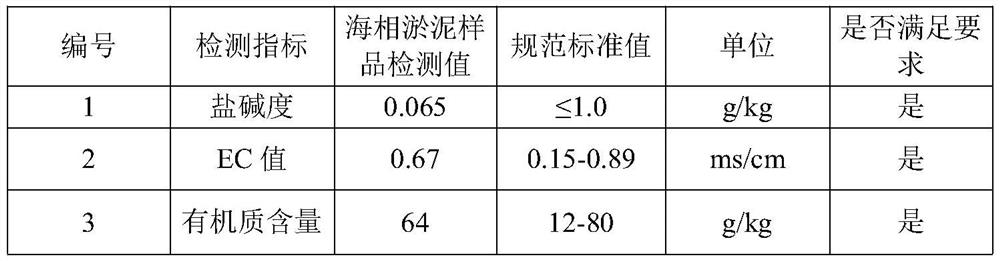

Embodiment 3

[0072] The original incoming marine silt is the base material, and its mass fraction is 1 part; the mass fractions of other components relative to the marine silt are: 1 part of rice husk (and / or straw), 8 parts of sand, and 1 part of biochar parts, 10 parts of organic fertilizer, 1 part of desulfurization gypsum; according to the same steps of processing marine silt as in Example 1, after 28 days of soil conservation, the measured indexes are shown in Table 4. Compared with the data in Table 4, the salinity and alkalinity of the improved marine silt decreased by 25.53, the EC value decreased by 0.91, and the organic matter content increased by 72.44.

[0073] Table 4

[0074]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com