Self-turning type denitration and desulfurization tower capable of efficiently adsorbing waste gas

A desulfurization tower and high-efficiency technology, applied in the field of denitrification and desulfurization towers, can solve the problems of reducing the frequency of solid adsorbent replacement, local uneven distribution, and reducing the influence of waste gas treatment adsorption efficiency, so as to avoid local uneven distribution and achieve good adsorption. effect, effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

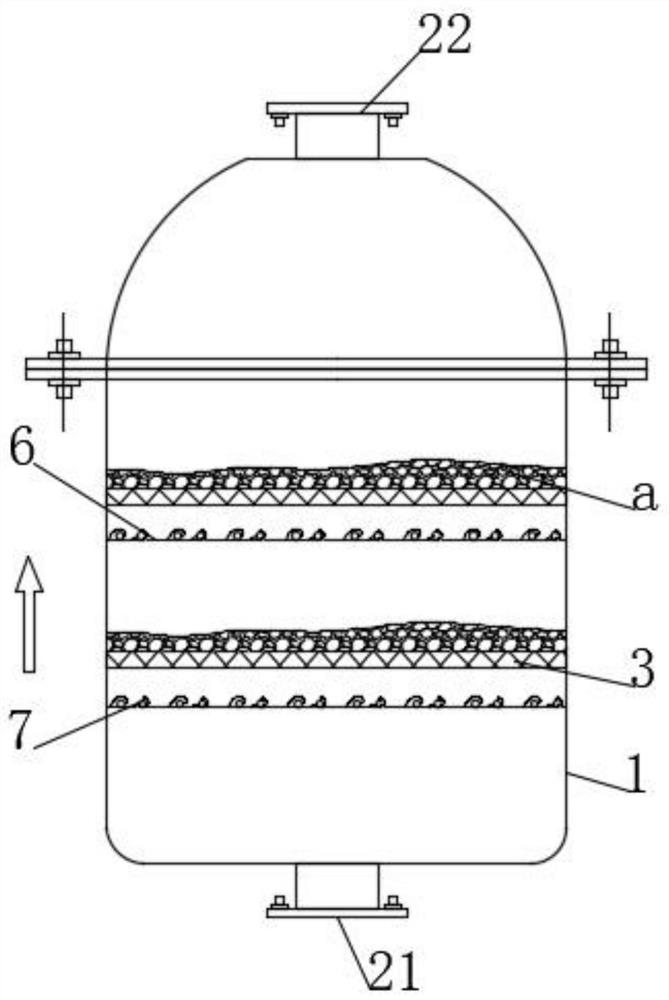

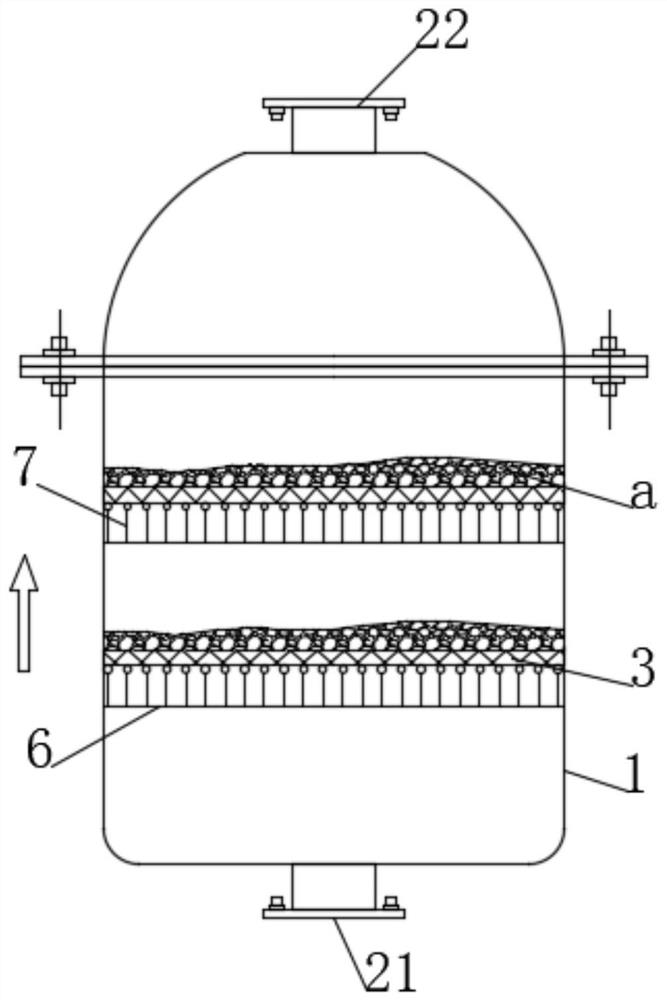

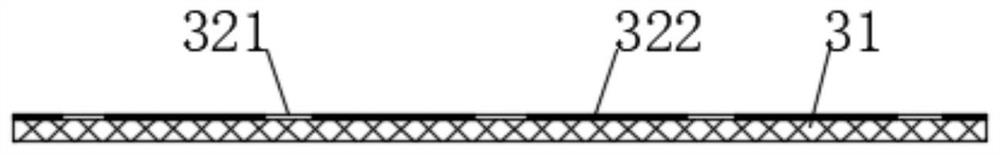

[0041] see figure 1 , a self-turning denitrification and desulfurization tower for efficient adsorption of exhaust gas, including a tower body 1, the upper and lower ends of the tower body 1 are fixedly connected with an inlet pipe 21 and an outlet pipe 22, and both the inlet pipe 21 and the outlet pipe 22 communicate with the tower body 1 , the inside of the tower body 1 is fixedly connected with a plurality of evenly distributed air filter laminates 3, and a solid adsorbent is placed above the air filter laminate 3. In the figure, a represents a solid adsorbent, and a plurality of air filter laminates 3 are provided below Pneumatic transposition mechanism, the pneumatic transposition mechanism includes a support grid plate 6 fixedly connected to the inner wall of the tower body 1, a plurality of uniformly distributed pneumatic balls 7 are fixedly connected above the support grid plate 6, and the pneumatic balls 7 include The pneumatic connecting rope fixedly connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com