Recyclable polymer sulfur dioxide absorbent

A sulfur dioxide and polymer technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as property changes and weak stability of small molecules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The absorbent consists of:

[0028] Polymer 30% (weight) of peroxybenzoic acid, 10% (weight) of sodium salicylate, 2.5% (weight) of malic acid, 7.5% (weight) of sodium nitrate, and the remainder is water.

[0029] Absorbent pH 3.

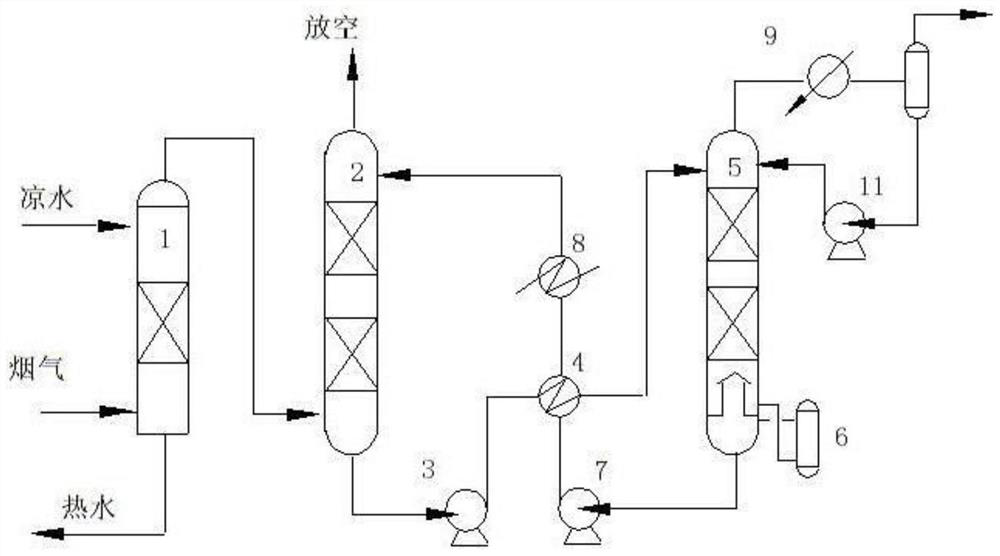

[0030] The absorbent is prepared by uniformly mixing the above-mentioned constituents in each content. The obtained absorbent composition is placed in a chemical plant such as figure 1 Absorption and desorption of SO by combustion acid production shown 2 during the process. Measured SO before recovery 2 The content is 21748mg / Nm 3 , SO after purification 2 The content is 21. The absorption rate of the composition to sulfur dioxide can reach 99.90%. Therefore, using this absorbent formula, the desulfurization efficiency is high, and the product SO 2 High gas content and stable quality.

Embodiment 2

[0032] The absorbent consists of:

[0033] 21% (weight) of polymer of peroxyketal, 15% (weight) of ether+methyl formate, 1.0% (weight) of citric acid, 10% (weight) of sodium chloride, and the rest is water.

[0034] Absorbent pH 4.

[0035] The absorbent is prepared by uniformly mixing the above-mentioned constituents in each content. The obtained absorbent composition is placed in a chemical plant such asfigure 1 Absorption and desorption of SO by combustion acid production shown 2 during the process. Measured SO before recovery 2 The content is 4730mg / Nm 3 , SO after purification 2 The content is 25. As a result, it was measured that the absorption rate of the composition to sulfur dioxide can reach 99.47%. Therefore, using this solution formula, the absorbent has a strong purification ability and can remove the SO in the flue gas. 2 Removal to 30mg / Nm 3 Below, achieve ultra-clean emissions.

Embodiment 3

[0037] The absorbent consists of:

[0038] 40% (weight) of the polymer of peroxybenzoic acid+peroxyketal, 5% (weight) of ether+methyl formate, 5% (weight) of tartaric acid, 5% (weight) of sodium chloride, and the rest of the ingredients It is water.

[0039] Absorbent pH 2.

[0040] The absorbent is prepared by uniformly mixing the above-mentioned constituents in each content. The obtained absorbent composition is placed in a chemical plant such as figure 1 Absorption and desorption of SO by combustion acid production shown 2 during the process. Measured SO before recovery 2 The content is 1453mg / Nm 3 , SO after purification 2 The content is 11. As a result, it is measured that the absorption rate of the composition to sulfur dioxide can reach 99.24%. Therefore, using this solution formula, the absorbent has a strong purification ability and can remove the SO in the flue gas. 2 Removal to 20mg / Nm 3 Below, achieve ultra-clean emissions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com