Homogenizing device for producing low-alkali cement by utilizing industrial waste residues

A technology for low-alkali cement and industrial waste residues, which is applied in cement mixing devices, clay preparation devices, and raw material supply devices for sale, etc., can solve the problems of insufficient homogenization accuracy, affecting the production quality of low-alkali cement, and inability to proportion, and improve the Production quality, avoid uneven crushing, ensure the effect of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

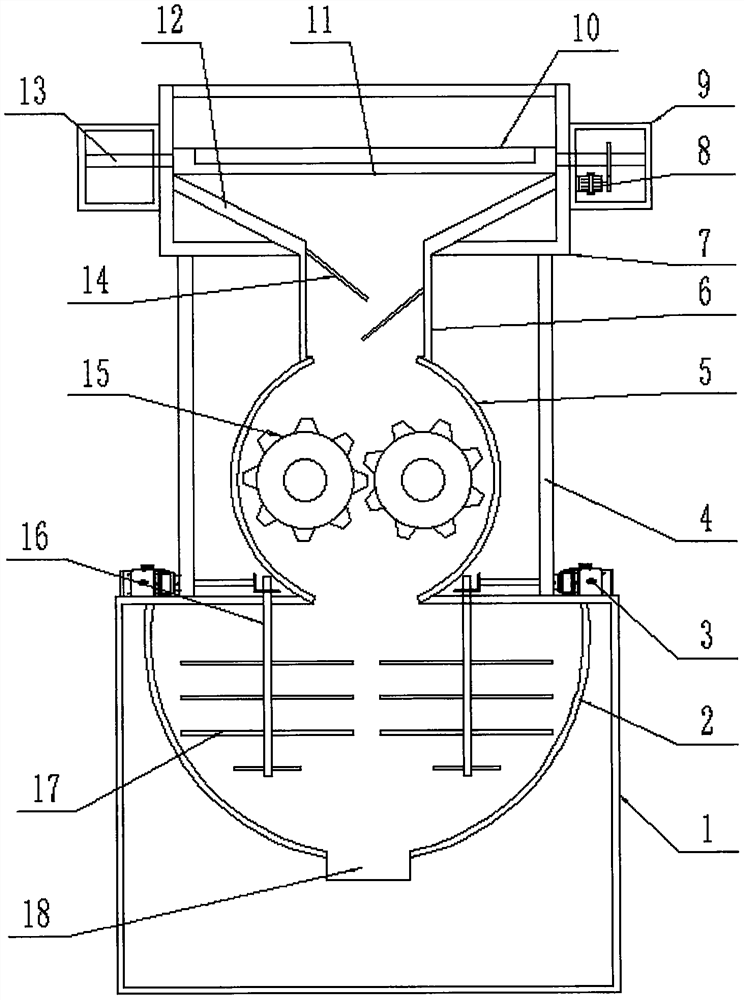

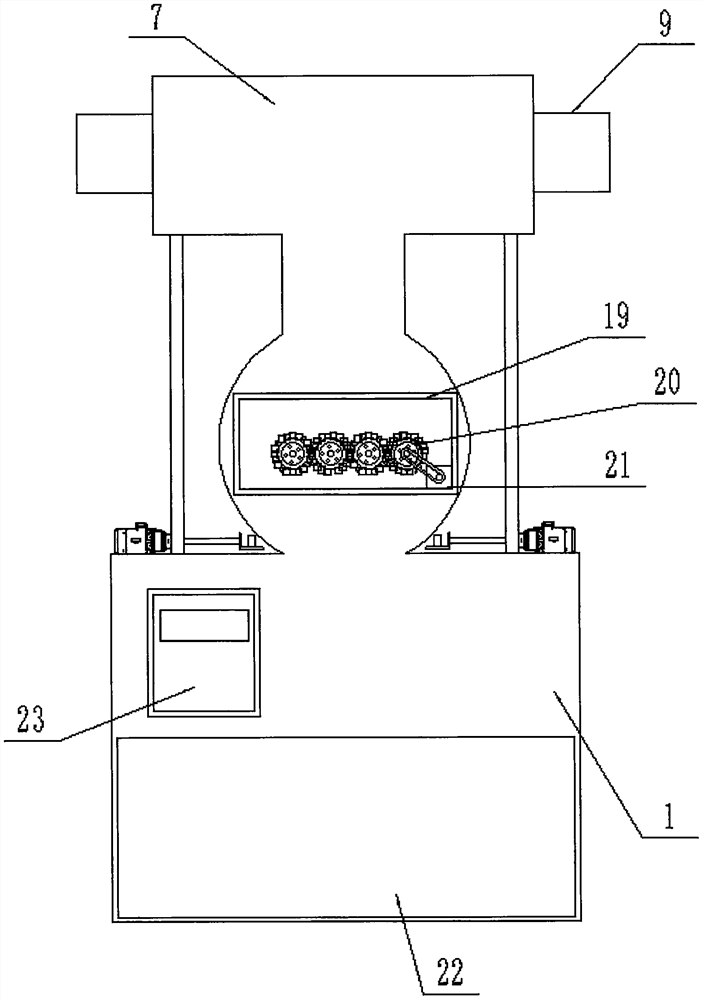

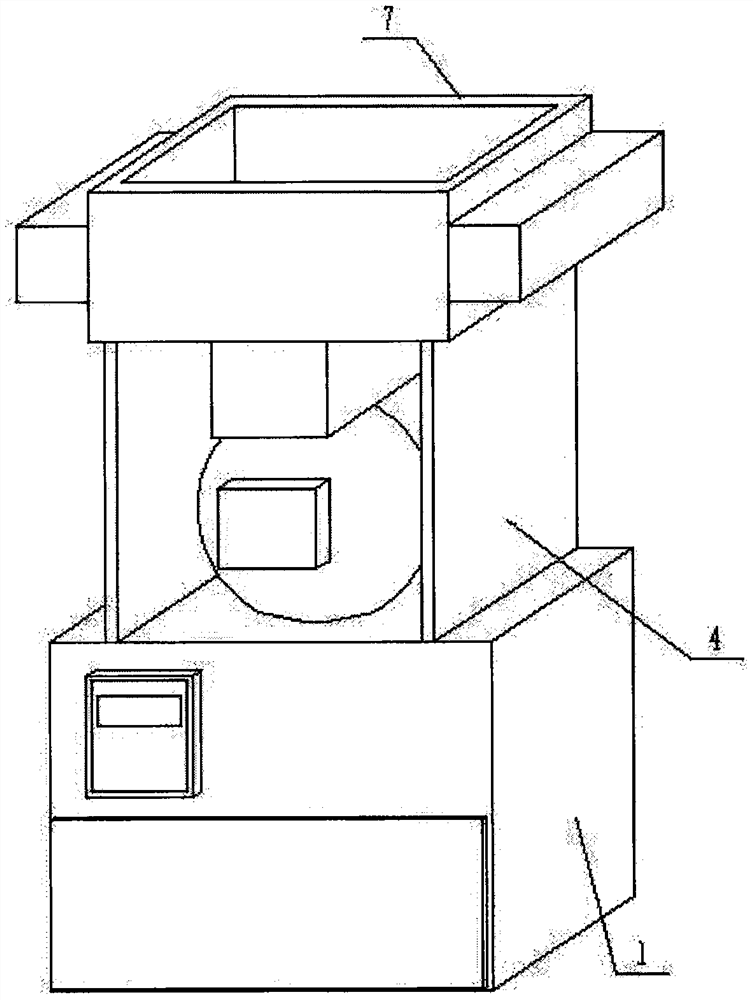

[0029] refer to Figure 1-3 , a homogenizing device for producing low-alkali cement by using industrial waste residue, comprising a tank body 1, a crushing tank 5, a material guide tank 6 and a feed tank 7, and the tank body 1 and the material guide tank 6 are respectively welded to two ends of the crushing tank 5 end, and the feed tank 7 is welded to the top of the feed tank 6, the two ends of the feed tank 7 are welded with a side box 9, and the side box 9 is provided with an overturning mechanism, and one end of the overturning mechanism is provided with a The weighing mechanism in the material tank 7, the side wall of the crushing tank 5 is welded with an auxiliary box 19, and the bottom end of the auxiliary box 19 is fixed with a No. 3 motor 21 by screws, and two Crushing roller 15, both sides of the top of the tank body 1 are fixed with a No. 1 motor 3 by screws, and the output shaft of the No. 1 motor 3 is fixed with a mixing frame 17 through a transmission assembly, an...

Embodiment 2

[0036] refer to Figure 4 , a homogenizing device for producing low-alkali cement by using industrial waste residues. Compared with Example 1, in order to ensure the problem of large dust pollution after the homogenization of cement raw materials, the side wall of the tank body 1 is provided with a purification mechanism, and the purification mechanism It includes a purification box 24, and a vacuum cleaner 25 is fixed inside the evolution box 24. The output end of the vacuum cleaner 25 is connected to the tank body 1, which can greatly avoid environmental pollution, and is energy-saving and environmentally friendly.

[0037] When in use, raw materials are added through the feeding tank 7, and the gravity sensor on the detection plate 10 detects the amount of raw materials added. When the predetermined weight is reached, the controller 23 controls to turn on the second motor 8 to drive the support table 11 to rotate, and the raw materials are poured into the equipment. The buf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com