Transparent ultrahigh-barrier composite film and preparation method thereof

A composite film, ultra-high technology, applied in the field of flexible packaging film, can solve the problems of limited application range, insufficient bonding force between the evaporated layer and the substrate film, etc., achieve the effects of less material and consumption, improved adhesion, and improved economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

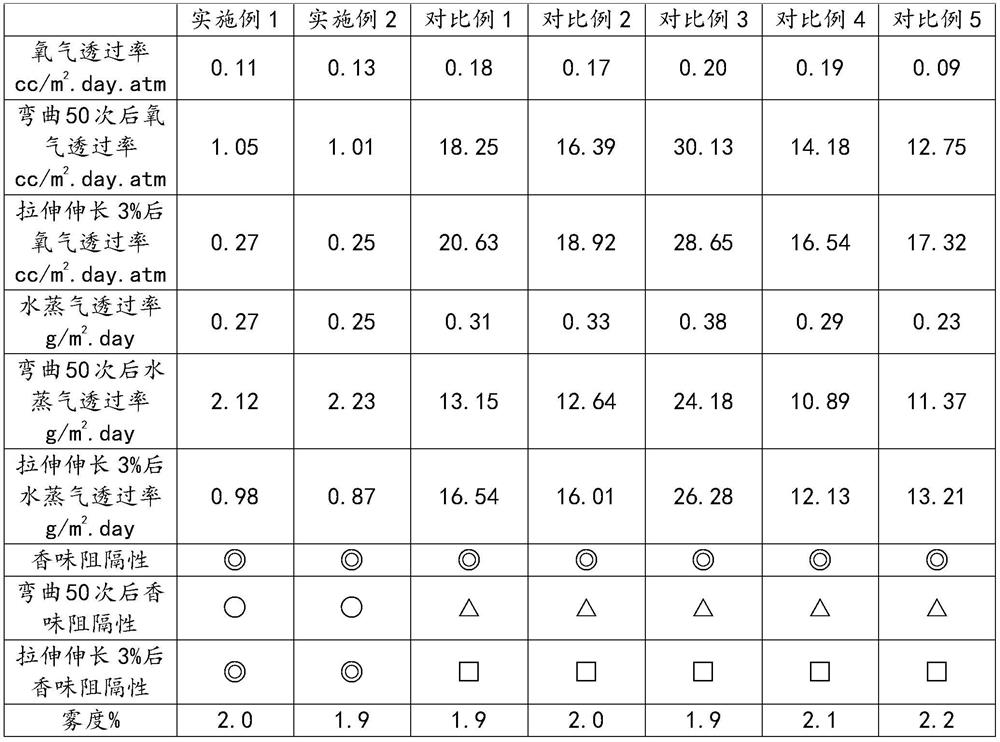

Examples

Embodiment 1

[0063] In this embodiment, a method for preparing a transparent ultra-high barrier composite film comprises the following steps:

[0064] 1) Preparation of substrate layer biaxially oriented polyamide film:

[0065] S1. Melt and plasticize all the raw materials through their respective extruders according to the proportion of the formula and flow them out through the hanger die. The temperature of each area is set at 250°C;

[0066] S2. Using a low-pressure air knife to attach the melt to the cold drum to form a thick sheet, wherein the thickness of the thick sheet is 180 μm, and the temperature of the cold drum is 20°C;

[0067] S3. After the thick sheet is heated, it is stretched synchronously with a magnetic levitation bidirectional stretching machine, wherein the stretching temperature is 195°C, and the stretching ratio is 3.0*3.3;

[0068] S4, heat-setting the stretched film, wherein the setting temperature is 210°C, the setting time is 8s, then the film is cooled and co...

Embodiment 2

[0101] The difference between Example 2 and Example 1 lies in that the composition and coating parameters of the coating solution for coating the protective layer and the vapor-deposited enhancement layer are adjusted, and the inorganic oxide in the vapor-deposited inorganic oxide is SiOx.

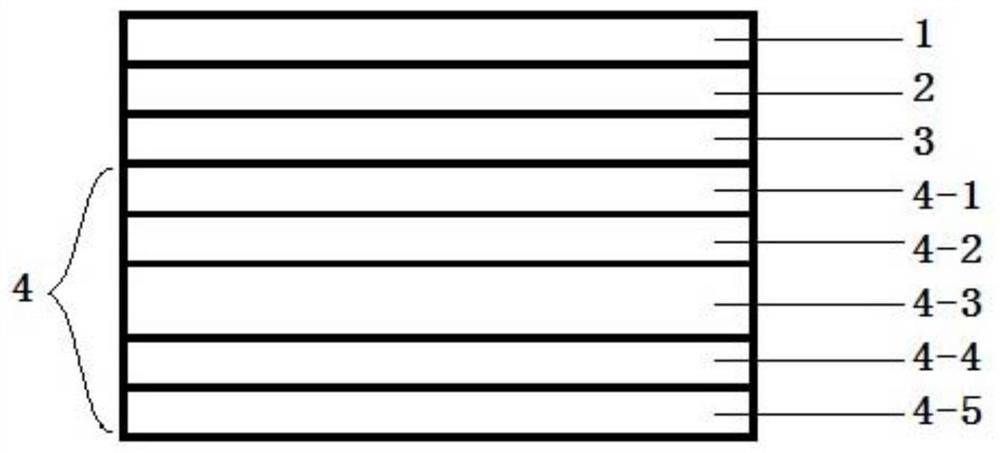

[0102] In this embodiment, a transparent and microwave-heatable high-barrier biaxially oriented polyamide composite film includes a four-layer film structure. Plating reinforcement and substrate layers.

[0103] The base material layer is a biaxially stretched polyamide film, and the polyamide in the base material layer is a PA6-PA66 copolymer. The substrate layer includes an upper surface layer, a first surface layer, an intermediate layer, a second surface layer and a lower surface layer, the inorganic oxide evaporation layer covers the evaporation enhancement layer, and the evaporation enhancement layer covers the upper surface layer; The upper surface layer is a biaxially stretched po...

Embodiment 5

[0249] The difference between Example 5 and Example 1 lies in that the coating parameters and preparation process conditions for coating the protective layer and the vapor deposition enhancement layer are adjusted.

[0250] In this embodiment, a transparent and microwave-heatable high-barrier biaxially oriented polyamide composite film includes a four-layer film structure. Plating reinforcement and substrate layers.

[0251] The base material layer is a biaxially stretched polyamide film, and the polyamide in the base material layer is a PA6-PA66 copolymer. The substrate layer includes an upper surface layer, a first surface layer, an intermediate layer, a second surface layer and a lower surface layer, the inorganic oxide evaporation layer covers the evaporation enhancement layer, and the evaporation enhancement layer covers the upper surface layer; The upper surface layer is a biaxially stretched polyamide film without corona treatment; the middle layer is a high-barrier EV...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com