A kind of bacterial strain producing biological emulsifier and the biological emulsifier produced by it

A biological emulsifier and sludge technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of environmental damage, easy to leave harmful chemical reagents, etc., to achieve good treatment, avoid environmental hazards, The effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

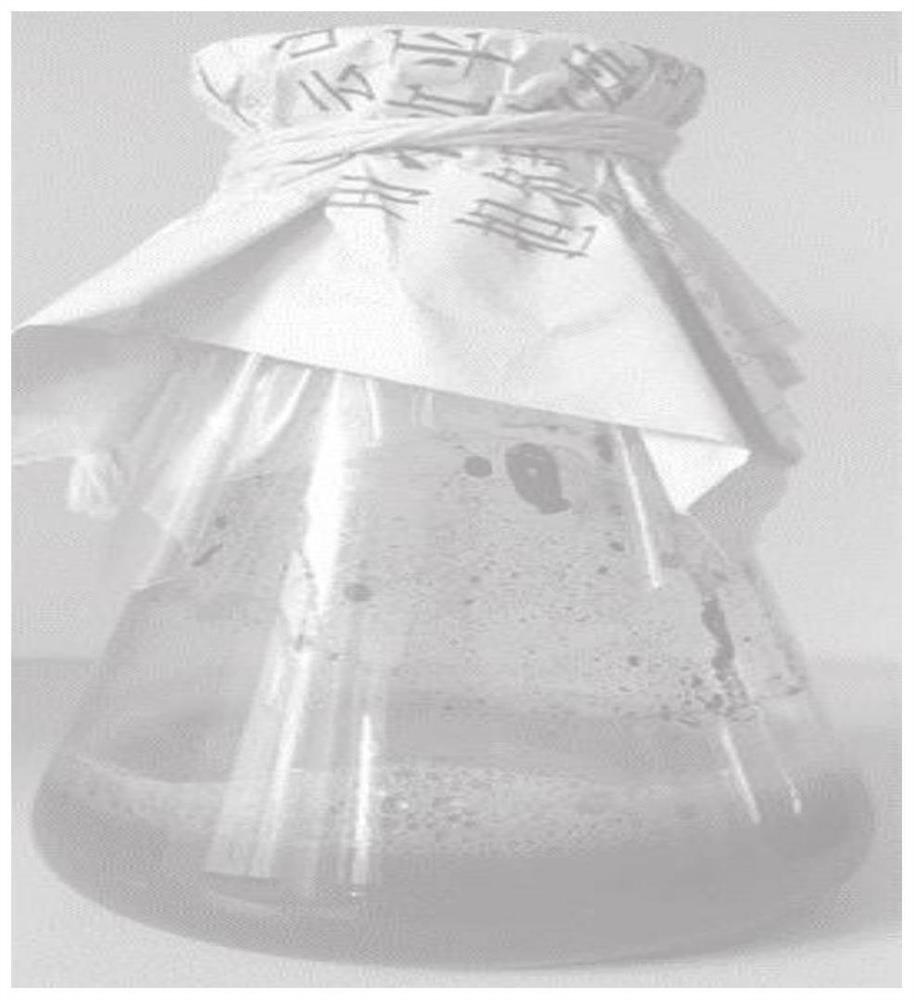

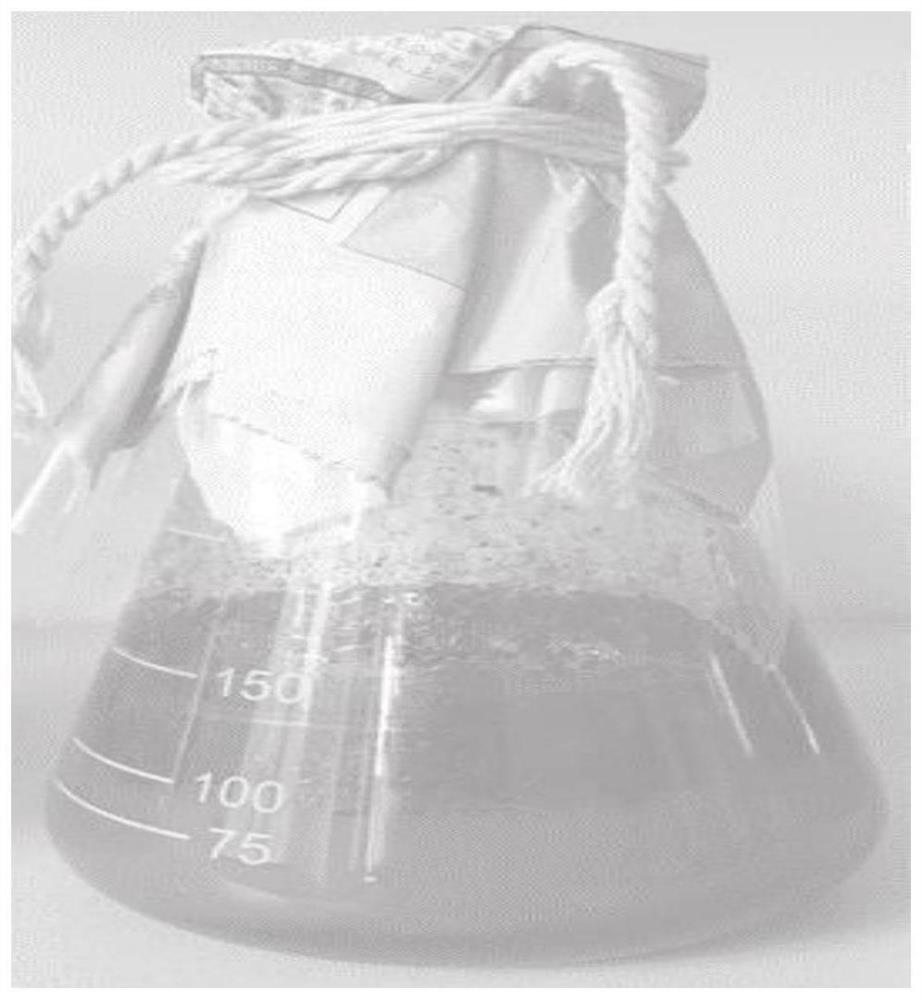

[0035] like figure 1 As shown, a method for treating oily sludge using the above-mentioned biological emulsifier of the present invention comprises the following steps:

[0036] S1, add 20 times the weight of water to the 5mL oily drill cuttings to be treated, then stir for 1h at a rotating speed of 30rpm, then adjust pH to 6 to obtain pretreated oily sludge;

[0037] S2. Add 0.5 g / L of the biological emulsifier at 45° C. and pH 5 to the pretreated oily sludge in step S1, and then stir at 30 rpm for 3 hours to obtain the treated oily sludge, The mass ratio of the pretreated oily sludge to the biological emulsifier is 20:1.

[0038] After testing, the initial oil content of oil-bearing drill cuttings was 15.48%, and the oil content of the samples treated with biological emulsifier was 1.57%. Transfer to a beaker such as figure 1 shown.

Embodiment 2

[0040] The difference with Example 1 is that in step S1, 20 times the weight of water is added to the 5mL tank bottom sludge to be treated. In step S2, 20 g / L of the biological emulsifier was added to the pretreated oily sludge in step S1. It was then stirred at 50 rpm for 4.5 h.

[0041] After testing, the initial oil content of the tank bottom sludge was 8.45%, and the oil content of the tank bottom sludge after the biological emulsifier treatment was 1.24%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com