High-vacuum surface-mounted miniature tuning fork quartz crystal resonator and manufacturing method thereof

A surface mount, quartz crystal technology, applied in the direction of electrical components, impedance networks, etc., can solve the problems of defective resonator quality, no treatment measures for gas impurities, etc., and achieve low equivalent impedance ESR, long service life, and sealing good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

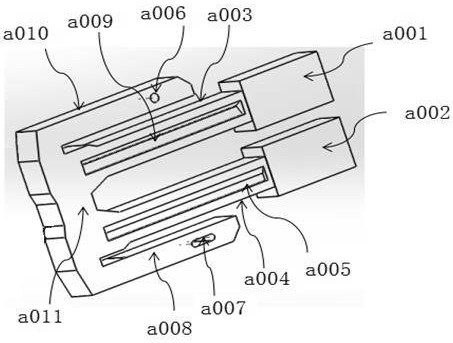

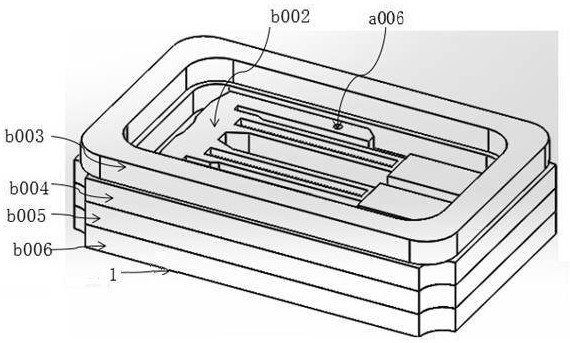

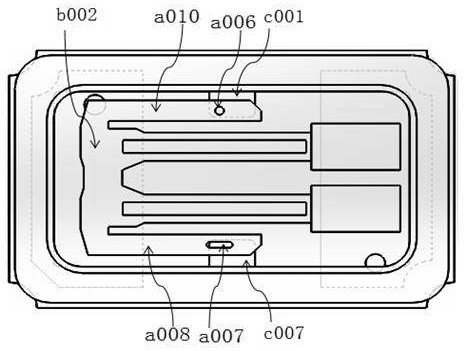

[0037] Micro tuning fork wafer structure see figure 1 , a high-vacuum surface-mounted miniature tuning fork quartz crystal resonator, comprising a ceramic base 1, a miniature tuning fork wafer b002 and a metal cover plate d001, the miniature tuning fork wafer b002 is located in the ceramic base 1, and the miniature tuning fork wafer b002 The electrodes of the ceramic base 1 are adhered to the internal electrodes of the ceramic base 1 through conductive glue, and the internal electrode lines of the ceramic base 1 are connected to the external electrodes of the ceramic base 1. The ceramic base 1 is composed of a ceramic bottom plate b006, a ceramic backing plate b005, The ceramic ring plate b004 and Kovar alloy ring b003 are superimposed sequentially from bottom to top. The ceramic ring plate b004 provides a height space for the tuning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com