Silica gel composition and silica gel prepared from same

A technology of silica gel composition and silica gel particles, which is applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of colloidal brittleness, solar pavement surface layer damage, surface hardness, etc., and achieve light transmission strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

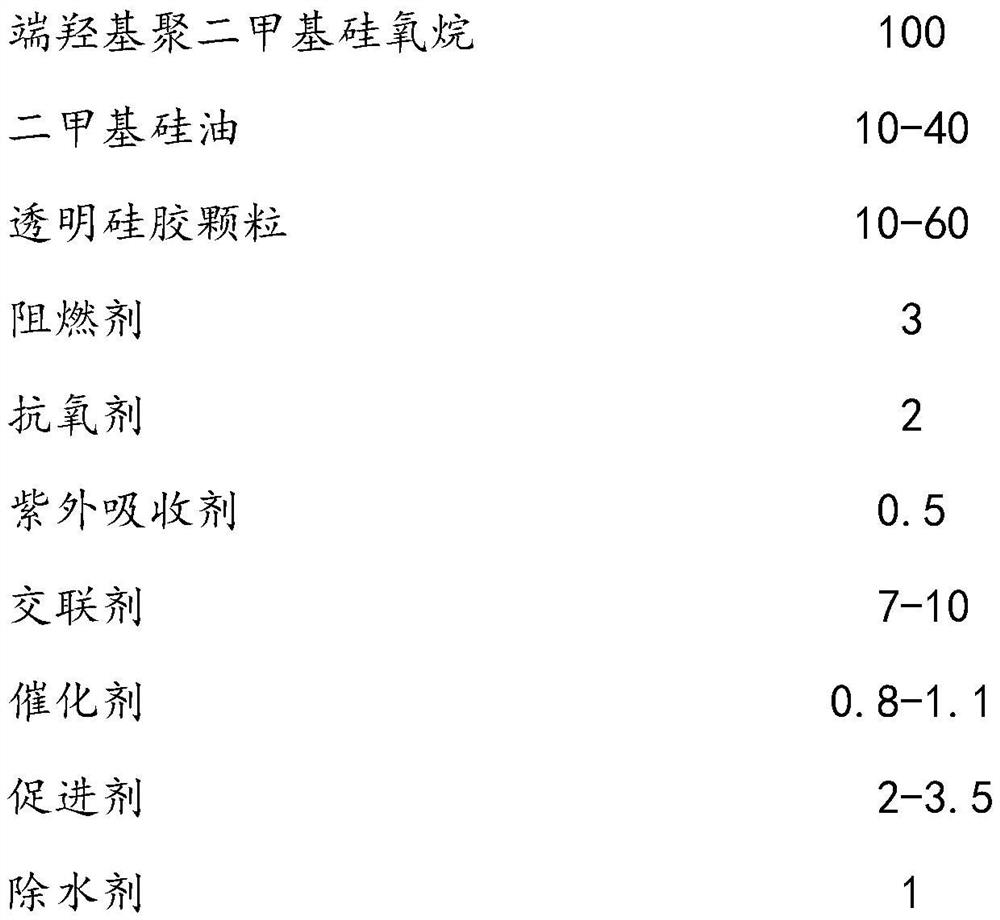

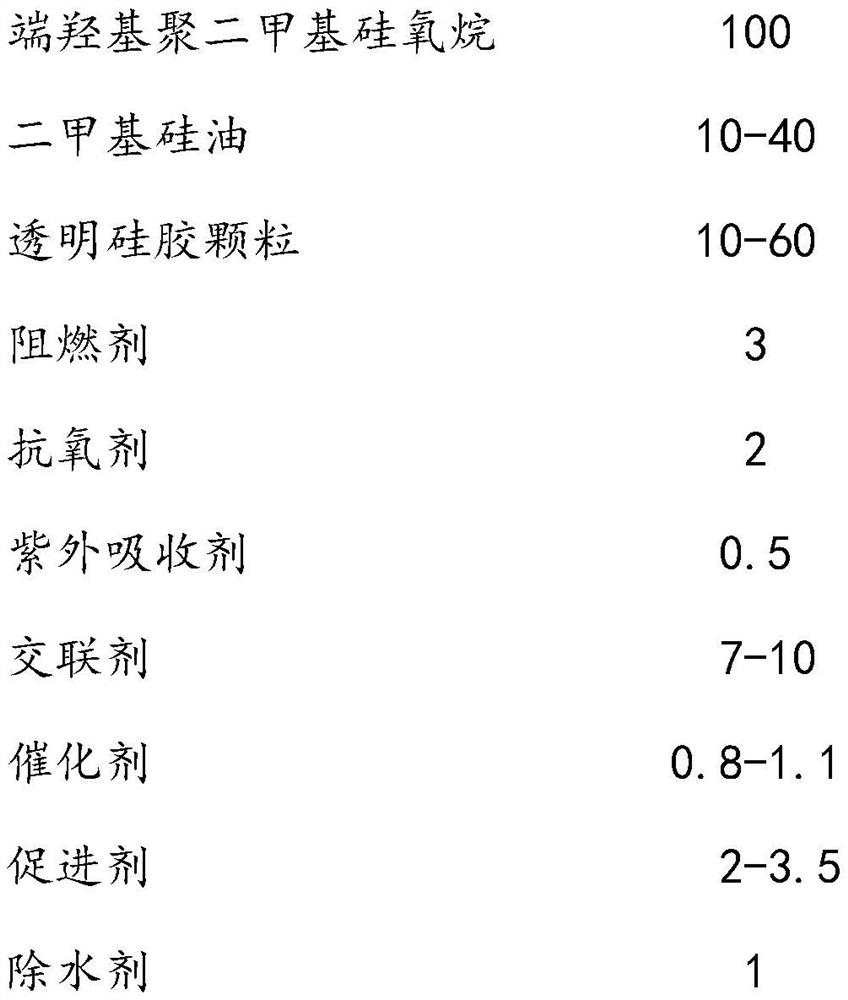

Method used

Image

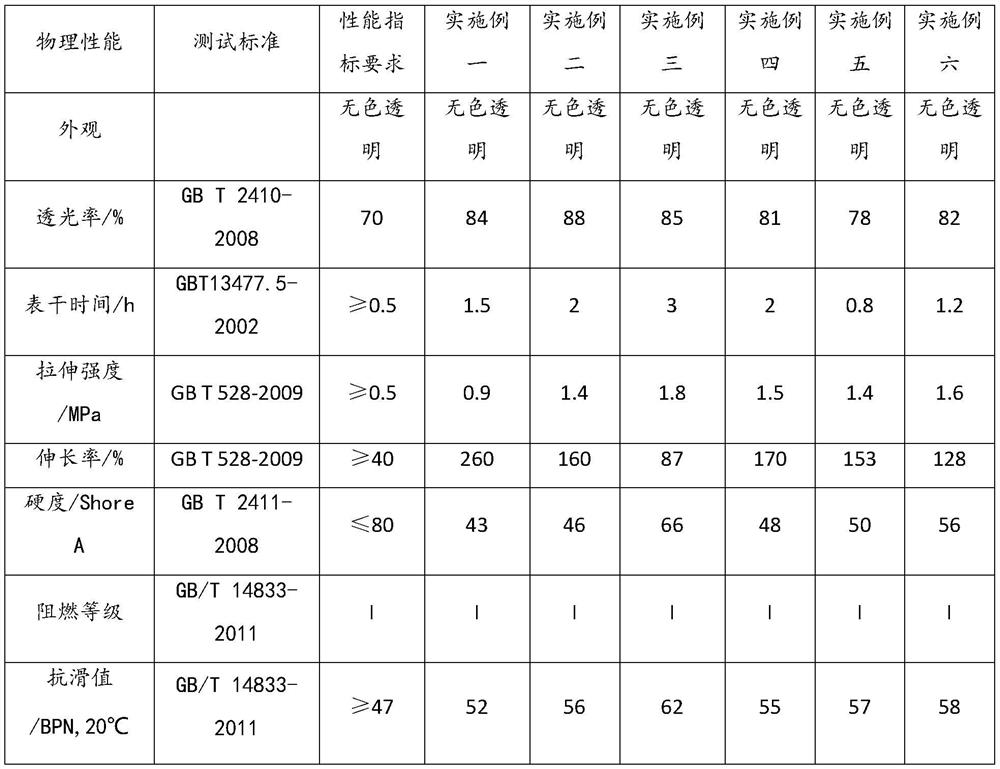

Examples

Embodiment 1

[0034] Embodiment 1 of the present invention provides a silica gel composition and silica gel prepared from the composition, specifically as follows:

[0035] Step 1: In parts by weight, weigh 100 g of hydroxyl-terminated polydimethylsiloxane (107 glue) (Zhejiang Hengyecheng Organic Silicon Co., Ltd.) with a viscosity of 80,000 mPa·s at room temperature and a viscosity of 500 mPa·s dimethyl Silicone oil (Jiangxi Xinghuo Organic Silicon Co., Ltd., 201 silicone oil-500cp) 30g, transparent silica gel particles with a particle diameter of 1-2mm (Longyu Cleaning Agent Factory in Rushan City) 50g, transparent silica gel particles with a particle diameter of 3-5mm (Longyu, Rushan City) Cleaning agent factory) 30g, nano-magnesium hydroxide (Suzhou Zemei New Material Technology Co., Ltd.) 2g, decabromodiphenyl ether (Jinan Jinyingtai Chemical Co., Ltd.) 1g, tetrakis[β-(3,5-di-tert-butyl- 4-Hydroxyphenyl) propionic acid] pentaerythritol ester (antioxidant 1010) (BASF (China) Co., Ltd.) ...

Embodiment 2

[0040] Embodiment 2 of the present invention provides a silica gel composition and silica gel prepared from the composition, specifically as follows:

[0041]Step 1: In parts by weight, weigh 80g of hydroxyl-terminated polydimethylsiloxane (107 glue) with a viscosity of 50000mPa·s at room temperature (Zhejiang Hengyecheng Silicone Co., Ltd.), and a viscosity of 8000mPa·s-terminated hydroxyl polydimethylsiloxane Methylsiloxane (107 glue) (Wuhan Tianzexin Technology Co., Ltd.) 20g, viscosity 1000mPa·s dimethyl silicone oil (Jiangxi Xinghuo Silicone Co., Ltd., 201 silicone oil-1000cp) 40g, transparent particle size 1-2mm Silica gel particles (Rushan City Longyu cleaning agent factory) 10g, transparent silica gel particles with a particle size of 2-3mm (Rushan City Longyu cleaning agent factory) 40g, transparent silica gel particles with a particle size of 3-5mm (Rushan City Longyu cleaning agent factory) ) 30g, aluminum hydroxide (Hefei Zhongke Flame Retardant New Material Co., L...

Embodiment 3

[0046] Embodiment 3 of the present invention provides a silica gel composition and silica gel prepared from the composition, specifically as follows:

[0047] Step 1: In parts by weight, weigh 60g of hydroxyl-terminated polydimethylsiloxane (107 glue) (Zhejiang Hengyecheng Silicone Co., Ltd.) with a viscosity of 50,000mPa·s at room temperature and a viscosity of 80,000mPa·s-terminated hydroxyl-polydimethylsiloxane Methylsiloxane (107 glue) (Zhejiang Hengyecheng Silicone Co., Ltd.) 40g, dimethyl silicone oil with a viscosity of 100mPa s (Jiangxi Xinghuo Silicone Co., Ltd., 201 silicone oil-100cp) 7g, with a viscosity of 1000mPa s Dimethyl silicone oil (Jiangxi Xinghuo Organic Silicon Co., Ltd., 201 silicone oil-1000cp) 3g, transparent silica gel particles with a particle diameter of 2-3mm (Rushan Longyu Cleaning Agent Factory) 60g, transparent silica gel particles with a particle diameter of 3-5mm (Rushan City Longyu Cleaning Agent Factory) 40g, nano magnesium hydroxide (Hefei ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com