Electrical element for computer data processing device and manufacturing method of electrical element

A technology for data processing devices and electrical components, applied in jewelry and other directions, can solve the problems of reducing the efficiency of tin plating, easy detachment of the tin plating layer, poor plating effect of the tin plating layer, etc. The effect of improving the binding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

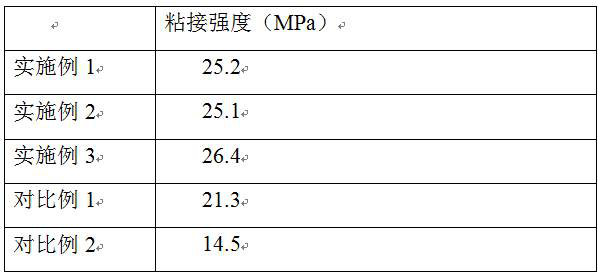

Examples

Embodiment 1

[0025] An electrical component for a computer data processing device in this embodiment includes a component base layer, and the component base layer is plated with a tin layer by an electroplating process. Dense coating;

[0026] The preparation method of the electroplating solution is: mix nickel sulfate and nickel chloride according to the weight ratio of 3:1, then send them into the reaction kettle for reaction, then add phosphoric acid to adjust the pH to 4.0, and then set the reaction temperature to 210°C The temperature reaction 10min, finally add the dispersing aid of nickel sulfate total amount 20%, continue to stir 20min, obtain electroplating solution;

[0027] The concrete preparation method of described dispersion aid is:

[0028] S1: Preparation of active liquid: put lanthanum chloride into a calciner for calcination, the calcination temperature is 800°C, the calcination time is 10min, then the temperature is lowered to 200°C at a rate of 5°C / min, and then the a...

Embodiment 2

[0038] An electrical component for a computer data processing device in this embodiment comprises a component base layer, and the component base layer is plated with a tin layer by an electroplating process. Dense coating;

[0039]The preparation method of the electroplating solution is: mix nickel sulfate and nickel chloride according to the weight ratio of 3:1, then send them into the reaction kettle for reaction, then add phosphoric acid to adjust the pH to 5.0, and then set the reaction temperature at 280°C The reaction temperature was 20min, and finally a dispersing aid of 30% of the total amount of nickel sulfate was added, and the stirring was continued for 30min to obtain an electroplating solution;

[0040] The concrete preparation method of described dispersion aid is:

[0041] S1: Preparation of active liquid: put lanthanum chloride into a calciner for calcination, the calcination temperature is 1200°C, the calcination time is 20min, then the temperature is lowered...

Embodiment 3

[0051] An electrical component for a computer data processing device in this embodiment includes a component base layer, and the component base layer is plated with a tin layer by an electroplating process. Dense coating;

[0052] The preparation method of the electroplating solution is: mix nickel sulfate and nickel chloride according to the weight ratio of 3:1, then send them into the reaction kettle for reaction, then add phosphoric acid to adjust the pH to 4.5, and then set the reaction temperature to 245°C React at a temperature of 15 minutes, and finally add a dispersing aid of 20-30% of the total amount of nickel sulfate, and continue to stir for 25 minutes to obtain an electroplating solution;

[0053] The concrete preparation method of described dispersion aid is:

[0054] S1: Preparation of active liquid: put lanthanum chloride into a calcination furnace for calcination, the calcination temperature is 1000°C, the calcination time is 15min, then the temperature is lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap