Ring cooler flue gas recycling system and method

A ring cooler and flue gas technology, applied in the field of iron and steel smelting, can solve problems such as increased costs, fire hazards, and non-utilization of flue gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

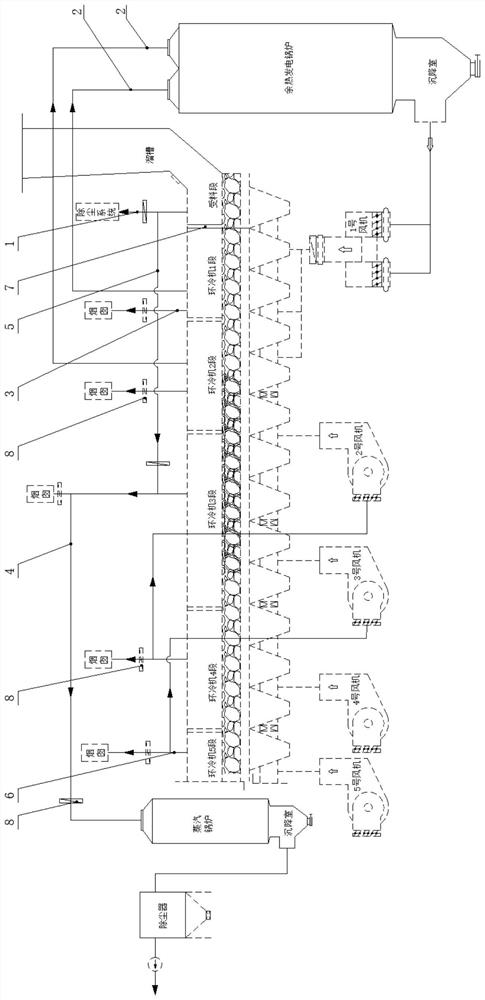

[0029] figure 1 It is a block diagram of a flue gas reuse system of an annular cooler related to an embodiment of the present invention. Shows the relationship between the various parts and links in the system.

[0030] like figure 1 As shown, in this embodiment, the annular cooler includes a chute, a material receiving section, an annular cooler 1 section, an annular cooler 2 sections, an annular cooler 3 sections, an annular cooler 4 sections, and an annular cooler 5 sections, and No. 1 fan, No. 2 fan, No. 3 fan, No. 4 fan, and No. 5 fan are arranged under the ring cooler. Among them, the 1st section of the annular cooler and the 2nd section of the annular cooler are high-temperature sections; the 3rd section of the annular cooler is a medium-temperature section; the 4th section of the annular cooler and the 5th section of the annular cooler are low-temperature sections. The No. 1 fan is used to blow cooling air into the material receiving section, the 1st section of the ...

Embodiment 2

[0045] In this embodiment, a method for reusing the flue gas of the annular cooler is provided, which is used to improve the utilization efficiency of the medium-temperature flue gas generated in the middle-temperature section of the annular cooler. The method includes:

[0046] Step S1. Collect the high-temperature flue gas generated by the material receiving section of the annular cooler, and introduce it into the flue gas collection device in the middle temperature section of the annular cooler.

[0047] Step S2, introducing the mixed flue gas in the flue gas collection device in the middle temperature section of the annular cooler into the waste heat utilization device. Preferably, the mixed flue gas is introduced into the steam boiler, and the waste heat of the mixed flue gas is used to heat the water in the boiler to generate steam.

[0048] Through this method, the calorific value of the medium-temperature flue gas collected in the flue gas collection device in the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com