Coreless optical fiber-based pumping and signal beam combiner and preparation method thereof

A coreless fiber and beam combiner technology, applied in lasers, laser parts, phonon exciters, etc., can solve the problems of high-efficiency transmission of pump light and signal light, and the inability of fiber bundles to be uniformly arranged. Achieve the effect of improving beam quality, improving signal optical coupling efficiency, high applicability and matching degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

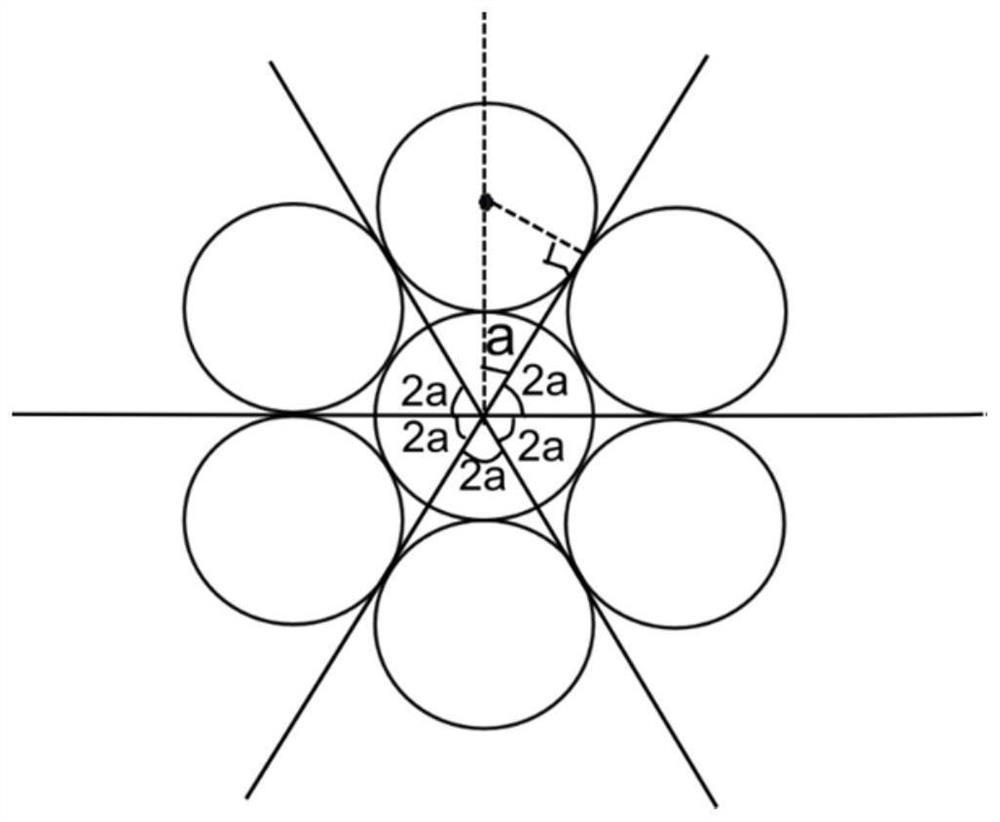

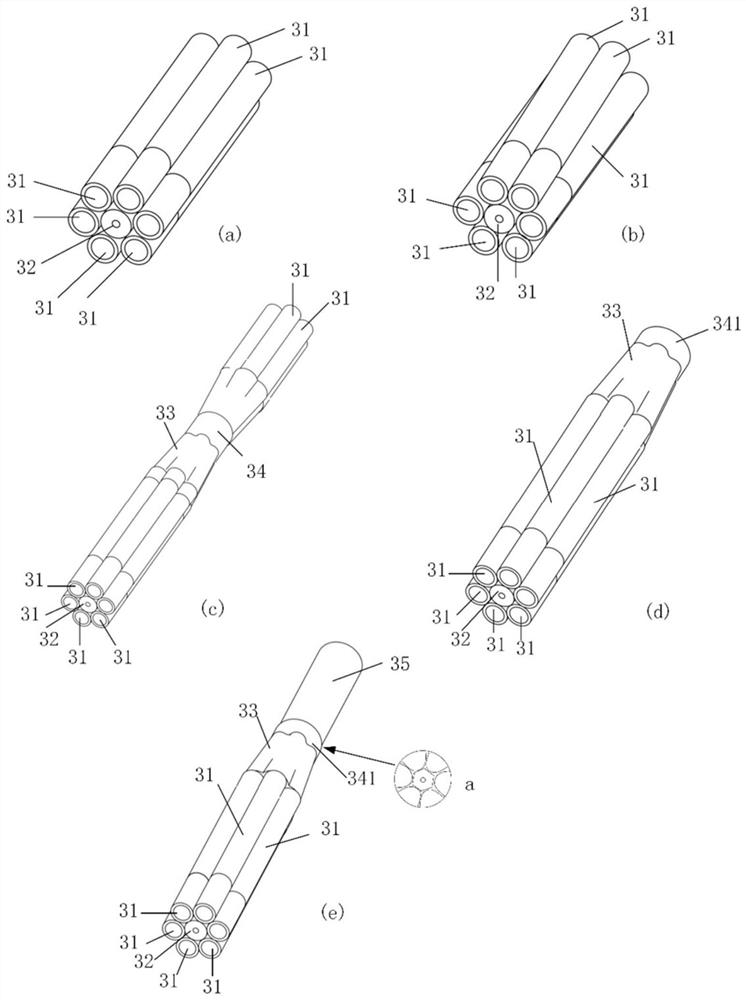

[0039]The pump and signal combiner in Embodiment 1 is (6+1)×1 type. Wherein, the original pumping fiber is a 220 / 242 μm (NA=0.22) multimode fiber. The cladding diameter of the coreless fiber can be selected between 242-250 μm, and the numerical aperture is 0.46NA. The core / cladding diameter of the signal fiber is 30 / 250 μm, corresponding to the numerical aperture (NA) of 0.06 / 0.46. The core / cladding diameter of the pump output fiber is 20 / 400 μm, and the corresponding numerical aperture (NA) is 0.06 / 0.46. The specific production steps are as follows:

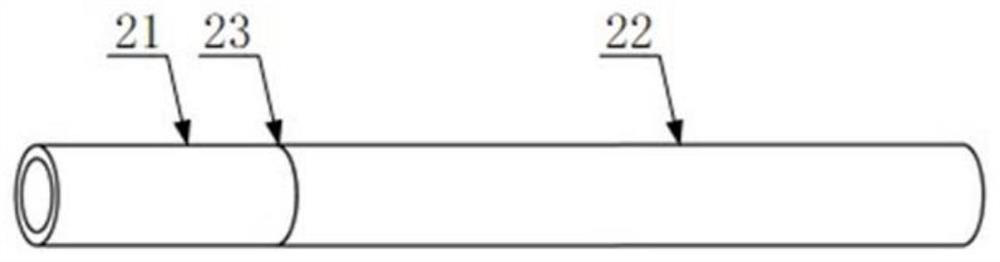

[0040] S1: The six pump injection fibers used in the preparation of the beam combiner are all formed by fusion splicing the original pump fiber and the coreless fiber. figure 2 It is a schematic diagram of the fusion splicing structure of the original pump fiber and the coreless fiber. Wherein, 21 is a schematic diagram of the original pumping fiber with the coating layer removed, and the general length is 10 mm. 22 is a s...

Embodiment 2

[0047] The pump and signal combiner in embodiment 2 is (6+1)×1 type. Wherein, the original pumping fiber is a 220 / 242 μm (NA=0.22) multimode fiber. The coreless fiber has a cladding diameter of 160 μm and a numerical aperture of 0.46NA. The core / cladding diameter of the signal fiber is 25 / 250μm, corresponding to the numerical aperture (NA) of 0.06 / 0.46. The core / cladding diameter of the pump output fiber is 20 / 400 μm, and the corresponding numerical aperture (NA) is 0.06 / 0.46. The specific production steps are as follows:

[0048] S1: The six pump injection fibers used in the preparation of the beam combiner are all formed by fusion splicing the tapered original pump fiber and the coreless fiber. Strip off the coating layer of the original pump fiber by 20-30mm, and taper the original pump fiber, so that the diameter of the fiber taper waist after tapering is about 160μm, the length of the equal diameter area is about 2mm, and the transition between the left and right sides...

Embodiment 3

[0054] The pump and signal combiner in Embodiment 3 is (6+1)×1 type. Wherein, the original pumping fiber is a 220 / 242 μm (NA=0.22) multimode fiber. The coreless fiber has a cladding diameter of 125 μm and a numerical aperture of 0.46NA. The core / cladding diameter of the signal fiber is 10 / 125μm, corresponding to the numerical aperture (NA) of 0.08 / 0.46. The core / cladding diameter of the pump output fiber is 20 / 400 μm, and the corresponding numerical aperture (NA) is 0.06 / 0.46. The specific production steps are as follows:

[0055] S1: The six pump injection fibers used in the preparation of the beam combiner are all formed by fusion splicing the tapered original pump fiber and the coreless fiber. Strip the coating layer of the original pump fiber by 20-30mm, and taper the original pump fiber, so that the diameter of the fiber taper waist after tapering is about 125μm, the length of the equal-diameter area is about 2mm, and the transition between the left and right sides Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com