Preparation method of silk mask and product

A facial mask and silk technology, applied in cosmetic preparations, dressing preparations, skin care preparations, etc., can solve the problems of increased production costs and unutilized sericin, and achieve good flexibility and excellent skin care effects , the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

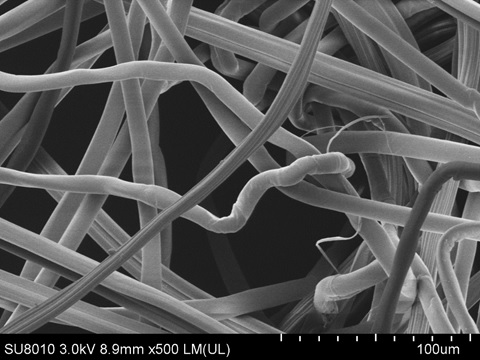

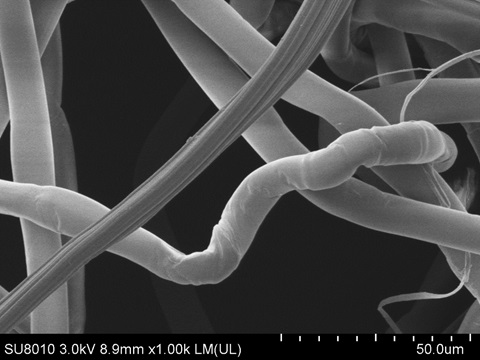

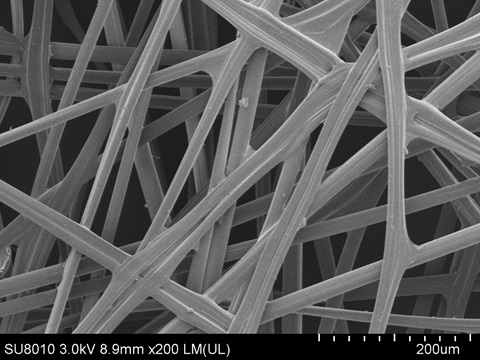

Image

Examples

Embodiment 1

[0046] A natural yellow flat silk mask made by the following steps:

[0047] (1) Place the silkworm of the natural yellow cocoon silkworm variety "Jinqiu×Chuyue" that is about to spin on a glass plate, and remove the silkworm after spinning to obtain natural yellow flat silk with a thickness of about 0.5mm, using physical methods ( Ultraviolet sterilization) cut into the shape of ordinary mask after sterilization.

[0048] (2) Soak the cut planar silk in 100ml of sterilized water for 12 hours at 4°C to fully soften it.

[0049] (3) Transfer the soaked and softened yellow planar silk into a 2% sericin essence (aqueous solution of 2% sericin protein) in a wet state (drained until no water drips), at a temperature of 4 Soak for 5 hours under the condition of ℃, take out and drain the liquid, dry in an environment with a temperature of 25 ℃ and a humidity of 40% for 1 hour, then put it into a new 2% sericin essence and soak it, repeat 4 times.

[0050] (4) After draining off exc...

Embodiment 2

[0052] A kind of flat silk mask of silkworm, is made by following steps:

[0053] (1) Place the silkworm of a common variety that is about to spin silk on a flat wooden board, remove the silkworm after silk spinning, and obtain white flat silk with a thickness of about 0.3 mm, which is cut into the shape of an eye mask after sterilization.

[0054] (2) Soak in 0.05% sodium bicarbonate solution at room temperature for 10 minutes to make the sericin fully swell, take it out and drain it, soak it in deionized water and wash it several times to remove the residual sodium bicarbonate.

[0055] (3) Soak the softened planar silk in 2% aseptic silk fibroin essence (2% silk fibroin aqueous solution) for 2 hours, take it out and drain for 10 minutes at 40% humidity and 25°C (for the first time), soak in 3% aseptic silk essence for 2 hours, take it out and drain for 10 minutes at 40% humidity and 25°C (second time), place in 4% aseptic Soak mycelium essence for 2 hours (the third time),...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com