Silica gel-based composite drying agent and preparation method thereof

A composite drying and silica gel technology, which is applied in the direction of silicon compounds, separation methods, chemical instruments and methods, etc., can solve the problems of adverse effects of weapons and equipment, poor moisture absorption and drying effect, and low moisture absorption, so as to avoid the risk of liquid decomposition, Good commercial value, simple composition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

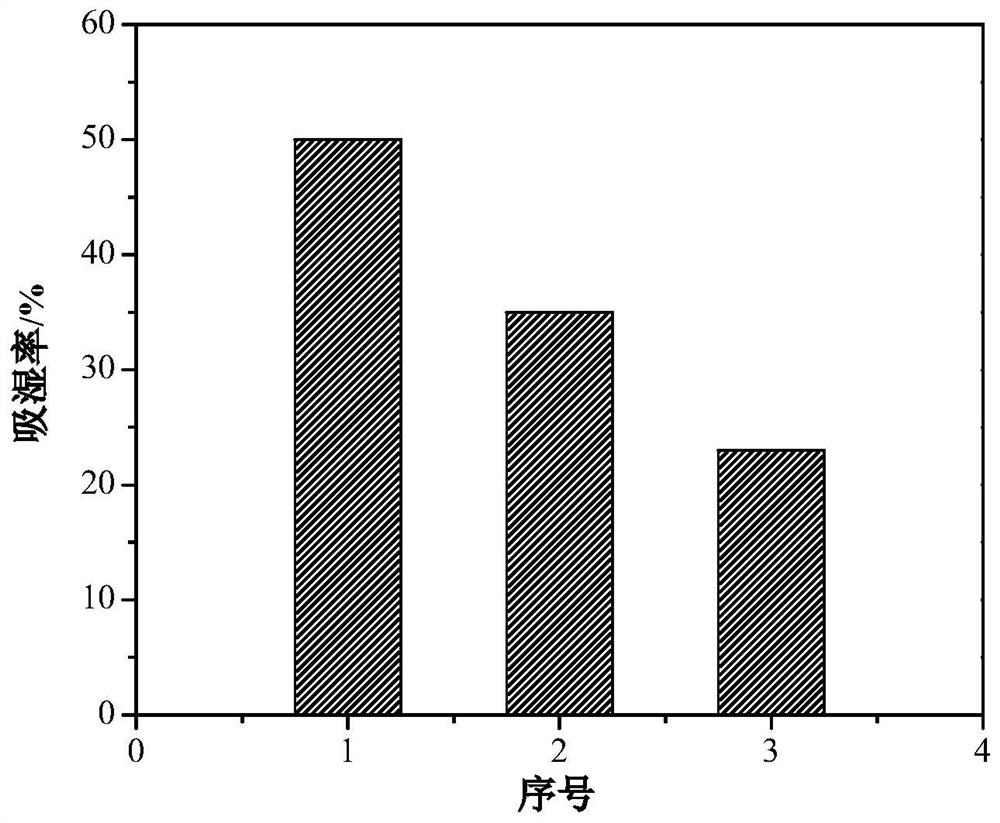

Embodiment 1

[0032] A silica gel-based composite desiccant, including a matrix and an immersion liquid,

[0033] In this embodiment, the substrate is porous silica gel, wherein the substrate includes the following components in parts by weight: 90 parts of coarse-pore silica gel, 120 parts of medium-pore silica gel, and 120 parts of fine-pore silica gel.

[0034] In this embodiment, the soaking solution is an alcoholic solution; the preparation method of the alcoholic solution is as follows: 25 parts by weight of calcium chloride, 10 parts by weight of lithium chloride, and 25 parts by weight of sodium chloride are mixed and dissolved in 400 parts of absolute ethanol and fully dissolved Get it later.

[0035] In this embodiment, a preparation method of a silica gel-based composite desiccant comprises the following steps:

[0036] (1) Calcium chloride, lithium chloride and sodium chloride are added to 400 parts of absolute ethanol according to weight and fully dissolved to obtain an alcoho...

Embodiment 2

[0041] A silica gel-based composite desiccant, including a matrix and an immersion liquid,

[0042] In this embodiment, the substrate is porous silica gel, wherein the substrate includes the following components in parts by weight: 100 parts of coarse-pore silica gel, 110 parts of medium-pore silica gel, and 110 parts of fine-pore silica gel.

[0043] In this embodiment, the soaking liquid is an alcoholic solution; the preparation method of the alcoholic solution is as follows: 25 parts by weight of calcium chloride, 25 parts by weight of lithium chloride, and 25 parts by weight of sodium chloride are mixed and dissolved in 400 parts of absolute ethanol and fully dissolved Get it later.

[0044] In this embodiment, a preparation method of a silica gel-based composite desiccant comprises the following steps:

[0045] (1) Calcium chloride, lithium chloride and sodium chloride are added to 400 parts of absolute ethanol according to weight and fully dissolved to obtain an alcohol...

Embodiment 3

[0050] A silica gel-based composite desiccant, including a matrix and an immersion liquid,

[0051]In this embodiment, the substrate is porous silica gel, wherein the substrate includes the following components in parts by weight: 120 parts of coarse-pore silica gel, 90 parts of medium-pore silica gel, and 90 parts of fine-pore silica gel.

[0052] In this embodiment, the soaking liquid is an alcoholic solution; the preparation method of the alcoholic solution is as follows: 25 parts by weight of calcium chloride, 10 parts by weight of lithium chloride, and 10 parts by weight of sodium chloride are mixed and dissolved in 400 parts of absolute ethanol and fully dissolved Get it later.

[0053] In this embodiment, a preparation method of a silica gel-based composite desiccant comprises the following steps:

[0054] (1) Calcium chloride, lithium chloride and sodium chloride are added to 400 parts of absolute ethanol according to weight and fully dissolved to obtain an alcoholic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com