Silver-loaded diatom shell antibacterial ceramic filter core and preparation method thereof

A technology of silver diatom frustule and antibacterial ceramics, which is applied in the field of silver-loaded diatom frustule antibacterial ceramic filter element and its preparation, which can solve the problems of serious damage to porous structure, low compressive strength of ceramic filter element, reduced antibacterial and water purification performance, etc. , to meet the requirements of green environmental protection and ecology, improve the effect of water purification, and the effect of excellent adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

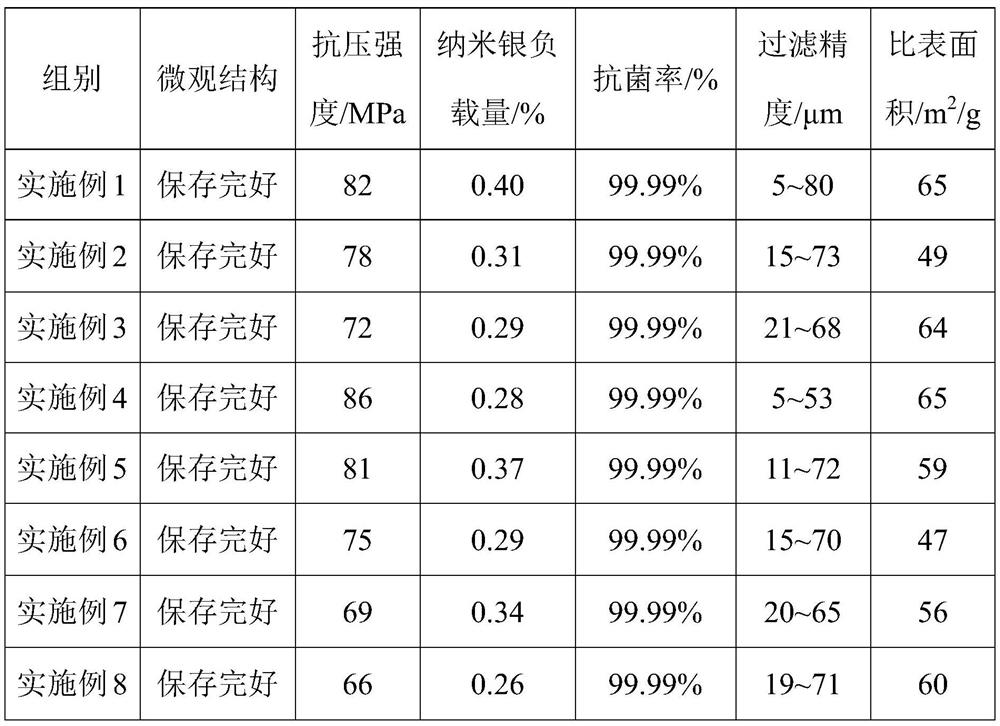

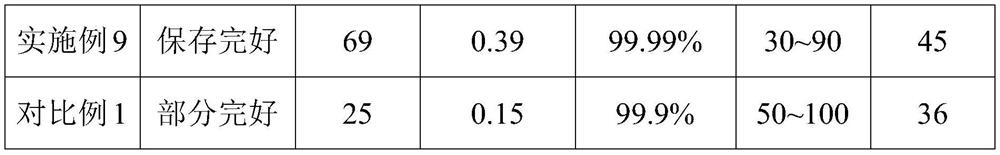

Examples

Embodiment 1

[0069] This embodiment provides a method for preparing a silver-loaded diatom frustule antibacterial ceramic filter element, the preparation method comprising the following steps:

[0070] (1) In terms of mass percentage, weigh 90% of silver-loaded diatom frustules, 4% of carbon powder as porogen, 4% of alumina powder as sintering aid, and hydroxymethyl cellulose as adhesive 2% raw material particles were mixed, and then ball milled at a speed of 300 rpm for 2 hours to obtain a mixed powder with a particle size of <45 μm;

[0071] Wherein, the preparation method of the silver-loaded diatom frustule includes: first soaking the diatom frustule produced by Shenzhen Taili Energy Company in a hydrochloric acid solution with a mass concentration of 5% for 3 hours, and then washing the filtered diatom frustule with water to pH =6.5~7.5, then dried at 70°C for 2h; then calcined in an air atmosphere at 600°C for 2h; then immersed the calcined diatom frustules in a silver nitrate soluti...

Embodiment 2

[0075] This example provides a method for preparing a silver-loaded diatom frustule antibacterial ceramic filter element, except that the temperature of hot pressing and sintering in step (3) is replaced by "900°C" from "800°C", other conditions are the same as in Example 1 exactly the same.

Embodiment 3

[0077] This example provides a method for preparing a silver-loaded diatom frustule antibacterial ceramic filter element, except that the temperature of hot pressing and sintering in step (3) is replaced by "500°C" from "800°C", other conditions are the same as in Example 1 exactly the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com