A kind of low hardness two-component addition type liquid fluorosilicone rubber and its preparation method

A liquid fluorosilicon, addition molding technology, applied in the field of rubber materials, can solve the problem of reducing the yield of base rubber, and achieve the effect of improving reactivity, excellent physical and mechanical properties, and ensuring cross-linking activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

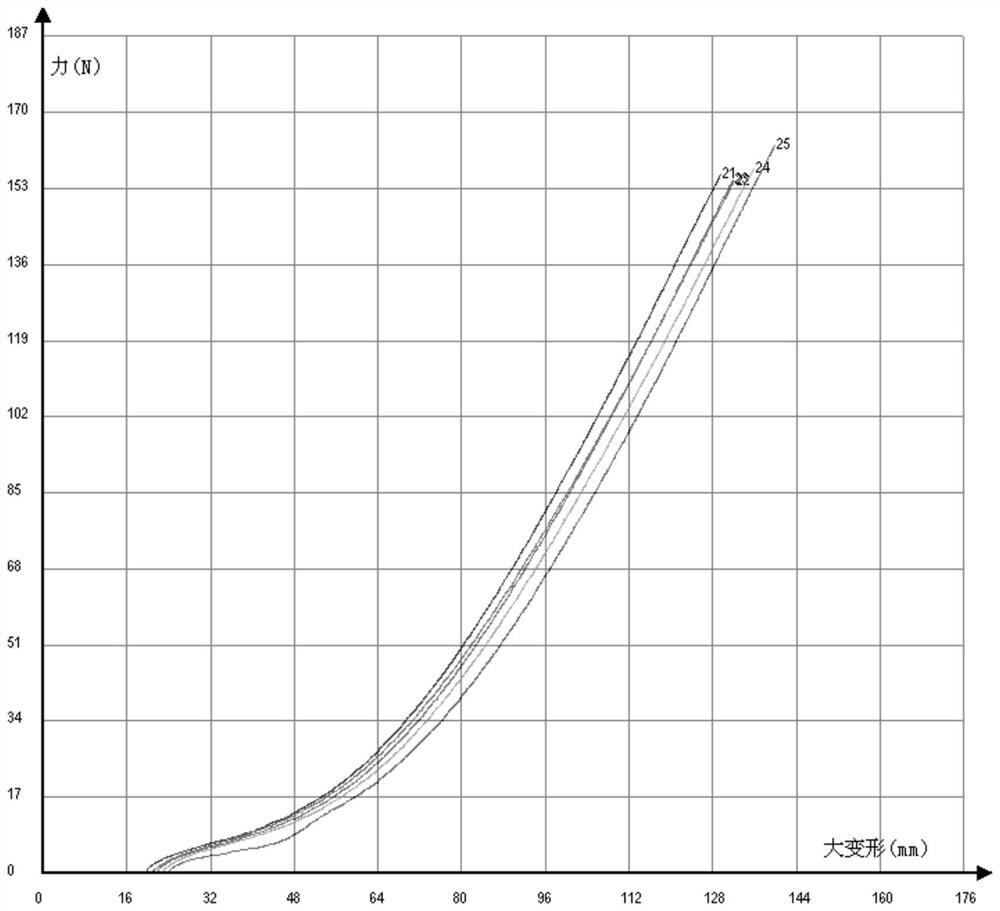

Image

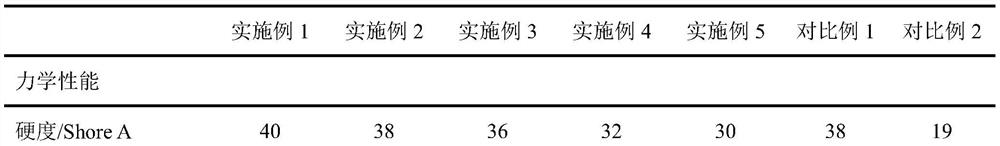

Examples

preparation example Construction

[0050] 1. Preparation of Fluorosilicone Base Rubber 1

[0051] Add 5000g of trimethyltris(3,3,3-trifluoropropyl)cyclotrisiloxane to the reaction kettle equipped with stirring and thermometer, and carry out dehydration treatment under the conditions of 60-80℃ and -0.099MPa for 2h ; After the dehydration was completed, adopt high-purity nitrogen to recover the pressure, and add 55g 1-vinyl-3-hydroxyl-1,1,3,3-tetramethyldisiloxane (purity 96%) and 4.2 g sodium fluorosiliconate catalyst (NaOH content 3.95%), turn on the heating, raise the temperature to 120-130°C for polymerization reaction, after the reaction starts, vacuumize to -0.05MPa and keep stirring for 3h; then, add 70g of 1-vinyl -3-Acetoxy-1,1,3,3-tetramethyldisiloxane (purity 98%) was neutralized and capped, and kept stirring for 8 hours; under the pressure of -0.099MPa, the system was heated to 200-220°C, remove small molecules with low boiling points, and cool down to obtain fluorosilicone base rubber 1, the structu...

Embodiment 1

[0068] The preparation of low-hardness two-component addition type liquid fluorosilicone rubber comprises the following steps:

[0069] (1) Add 1000g of fluorosilicone base rubber 1 (viscosity 30800cp, vinyl mass fraction 0.20%) into the vacuum kneader, and add 300g of fumed silica (hexamethyldisilazane hydrophobically modified , specific surface area 220m 2 / g, carbon content 3.05%) were added sequentially, and kneaded for 0.5h after each addition, then heated up to 180°C and kneaded for 1h, vacuumed to a pressure of -0.098MPa, continued kneading for 2h, and then lowered to room temperature;

[0070] (2) Take out the rubber material after kneading treatment, and use a three-roller grinder to pass it 3-5 times until the rubber material is uniform and fine, and there are no visible agglomerated particles;

[0071] (3) Take out 100g of the fully ground rubber material and place it on a three-roller grinder, add 0.7g of platinum catalyst (3000ppm of platinum content), 1g of ceri...

Embodiment 2

[0079] The preparation of low-hardness two-component addition type liquid fluorosilicone rubber comprises the following steps:

[0080] (1) Add 1000g of fluorosilicone base rubber 1 (viscosity 30800cp, vinyl mass fraction 0.20%) into the vacuum kneader, and add 300g of fumed silica (hexamethyldisilazane hydrophobically modified , specific surface area 220m 2 / g, carbon content 3.05%) were added sequentially, and kneaded for 0.5h after each addition, then heated up to 180°C and kneaded for 1h, vacuumed to a pressure of -0.098MPa, continued kneading for 2h, and then lowered to room temperature;

[0081] (2) Take out the rubber material after kneading treatment, and use a three-roller grinder to pass it 3-5 times until the rubber material is uniform and fine, and there are no visible agglomerated particles;

[0082] (3) Take out 100g of the fully ground rubber material and place it on a three-roller grinder, add 1g of platinum catalyst (3000ppm of platinum content), 1.5g of cerium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| volatile matter | aaaaa | aaaaa |

| volatile matter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com