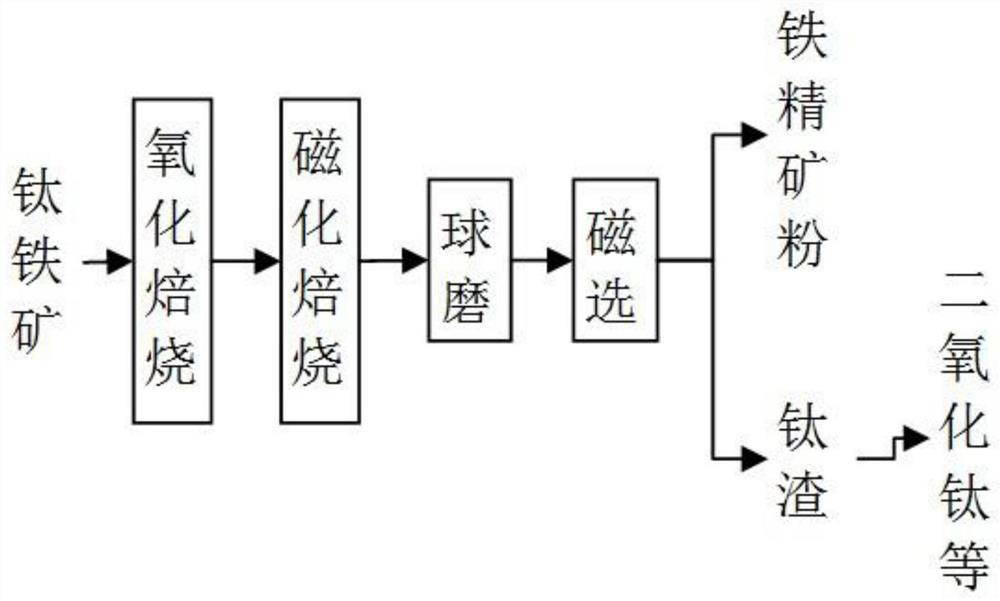

Ilmenite treatment method

A processing method, ilmenite technology, applied in chemical instruments and methods, magnetic separation, improvement of process efficiency, etc., can solve problems such as inability to obtain titanium and iron at the same time, serious environmental pollution, long process flow, etc., and achieve easy industrialization The effect of low production and smelting temperature and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

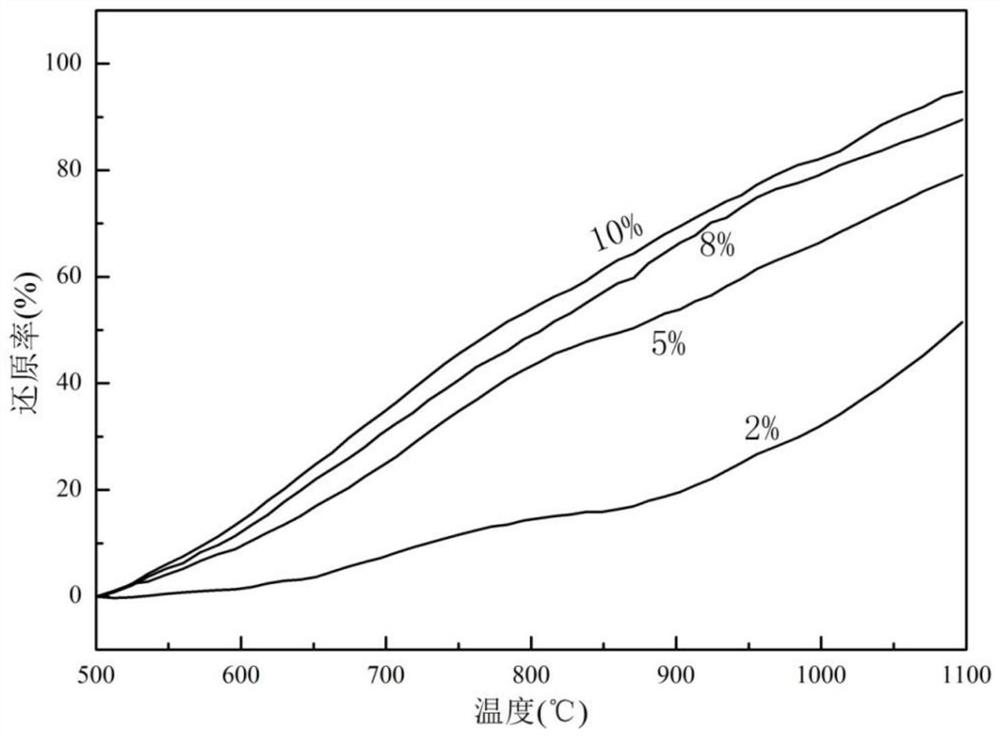

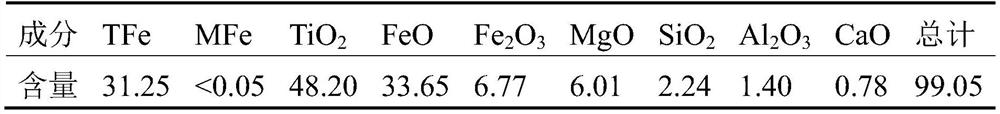

[0035] 1000g of ilmenite was oxidized and roasted in air at 900°C for 2 hours to obtain an oxidized ilmenite mixture;

[0036] Add 300g of Na to the oxidized titanium-iron mixture 2 B 4 o 7 Additives, and mixed with 100g of coal powder (carbon content 10%), put into the equipment for heating reduction, heating up to 1130 ° C, heating time 2 hours, 1130 ° C for 2 hours, after heating reduction is completed, take it out after cooling, and take it out The final product was subjected to chemical analysis.

Embodiment 2

[0038] Compared with Example 1, what is added is 150g coal powder (15% carbon content), and others are all the same.

Embodiment 3

[0040] Compared with embodiment 1, what add is 200g pulverized coal (20% of carbon content), other are all the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com