Silicon carbide crystal growth method and device

A technology of crystal growth and silicon carbide, applied in the directions of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems affecting crystal crystallization quality, affecting crystal quality, seed crystal nucleation, etc., to improve quality, avoid sublimation, avoid The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

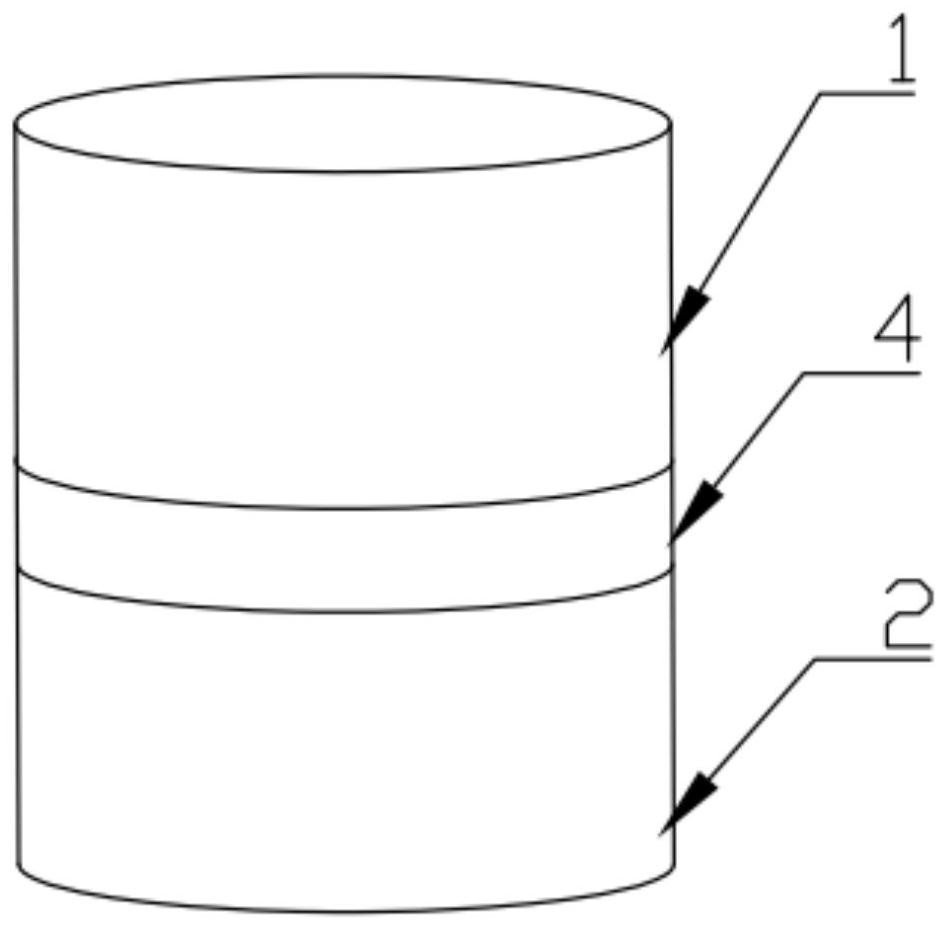

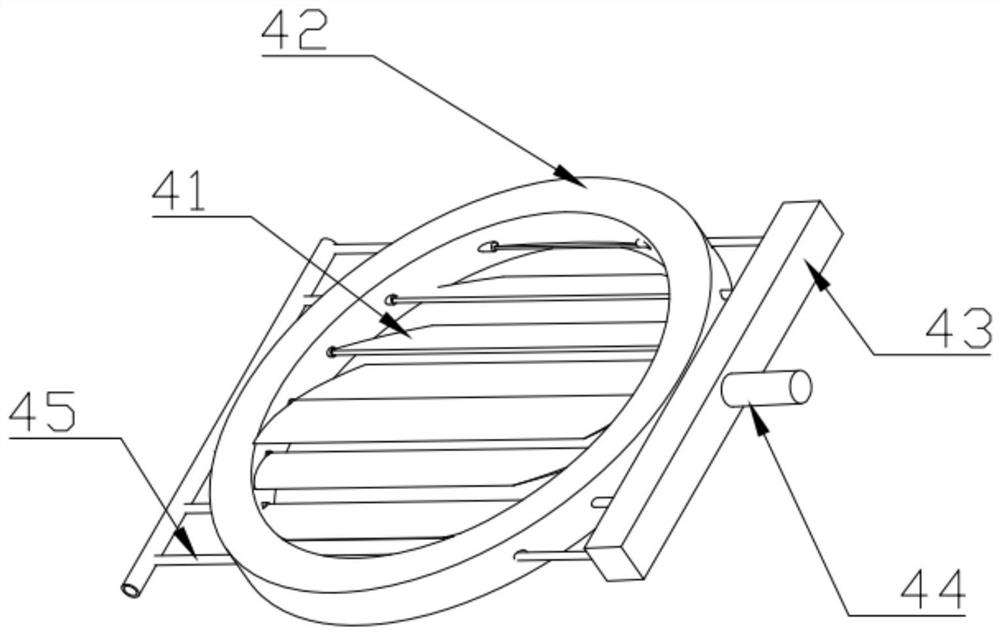

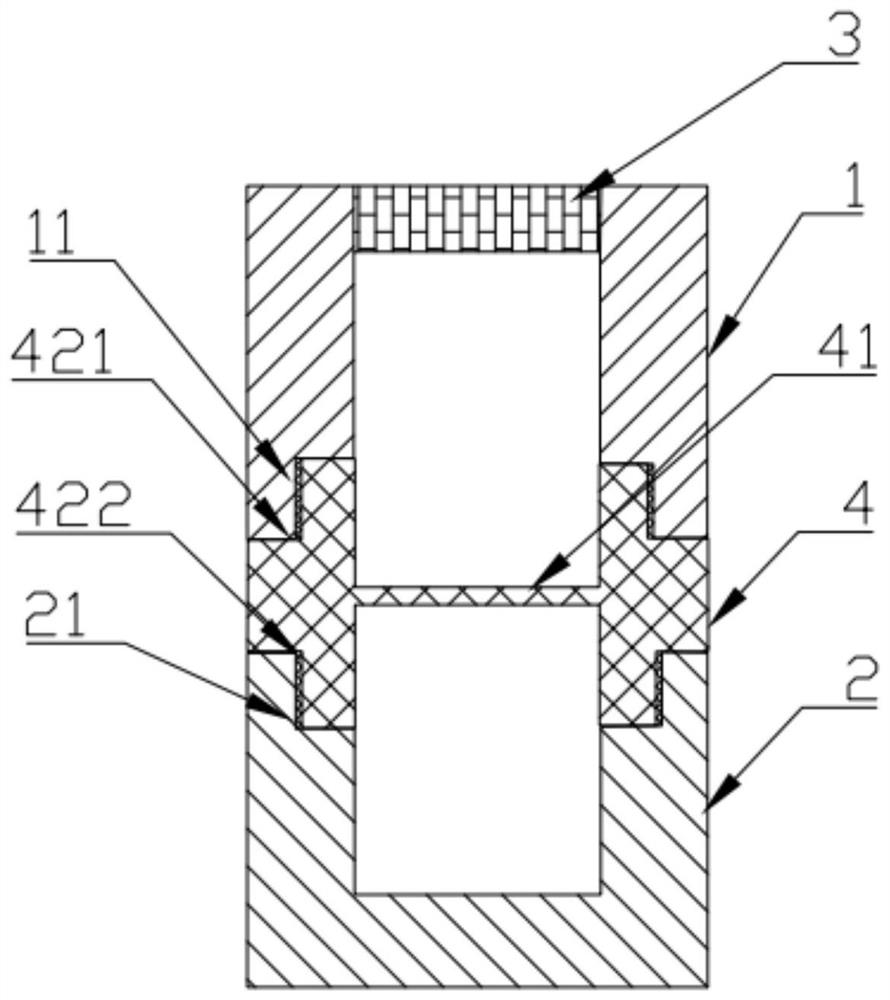

[0047] refer to Figure 1-3 , the present embodiment provides a device for growing silicon carbide crystals, the device includes a first crucible 1, a second crucible 2 and a heating device, the first crucible 1 is cylindrical with two ends open, and the second crucible 2 is arranged above There is a crucible cover 3; the second crucible 2 is cylindrical with one end open, and the second crucible 2 is located below the first crucible 1; the first crucible 1 and the second crucible 2 are connected to form an internal cavity, and a partition 41 is arranged in the cavity A plurality of partitions 41 rotate to no gap between the plurality of partitions 41 and between the partitions 41 and the cavity inner wall, then a plurality of partitions 41 cut off the first crucible 1 and the second crucible 2; a plurality of partitions 41 rotate When there are gaps between the plurality of partitions 41 and / or between the partitions 41 and the cavity, the first crucible 1 communicates with t...

Embodiment 2

[0061] In a specific embodiment, there is provided a method for preparing silicon carbide crystals using the above-mentioned silicon carbide crystal device, the method comprising the following steps:

[0062] (1) Assembly stage: bond the seed crystal on the top of the first crucible, place the silicon carbide raw material at the bottom of the second crucible, connect the first crucible and the second crucible to form an internal cavity, and set a plurality of rotatable partitions in the cavity plate;

[0063] (2) Heating and heating stage: place the assembled first crucible and second crucible in the crystal growth furnace, vacuumize the crystal growth furnace, and control the rotation of multiple partitions between the plurality of partitions and between the partitions and the There is no gap between the inner walls of the cavity, so that the first crucible is separated from the second crucible,

[0064] Heating to 1200-1800°C, and introducing protective gas, the pressure is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com