Rolling bearing fault detection method based on chromaticity theory

A rolling bearing and fault detection technology, which is applied in the testing of mechanical components, the testing of machine/structural components, and measuring devices, etc., can solve the problems of complex working conditions of rolling bearings, interference on the work site, etc., and achieves easy manual observation, good scalability, Calculation of convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

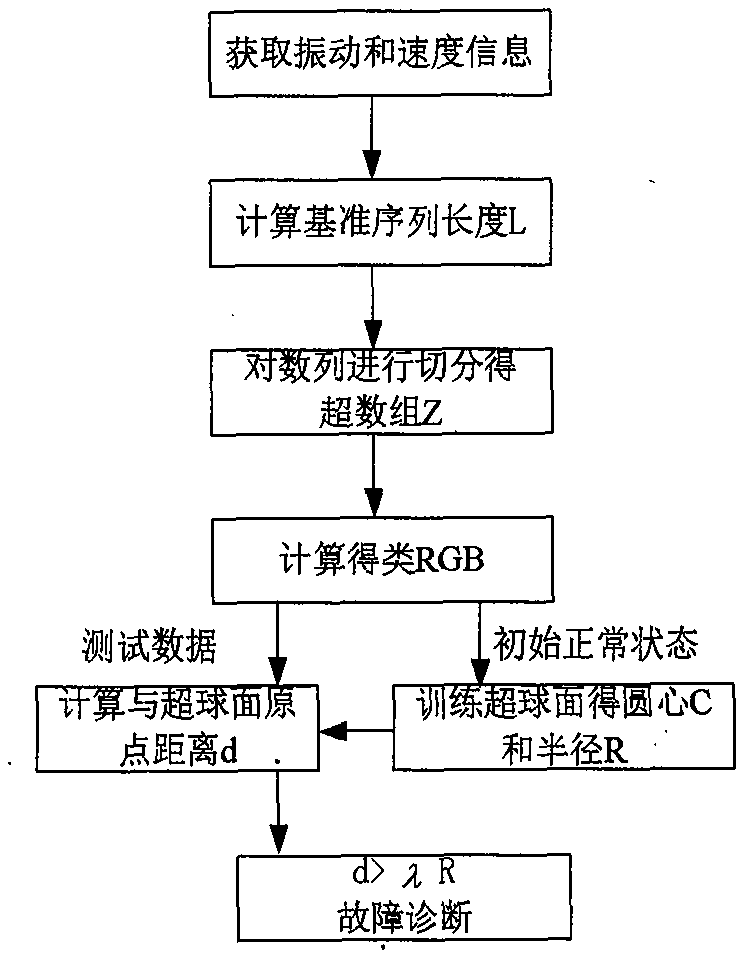

Method used

Image

Examples

Embodiment approach 1

[0043] The bearing test bench made by Case Western Reserve University includes a 2-horsepower motor, a torque sensor, a dynamometer and electronic control equipment. The bearing under test supports the motor shaft. A single point of failure was placed on the bearing using EDM technology. In the experiment, an acceleration sensor is used to collect vibration signals, and the acceleration sensor is installed at the 12 o'clock position of the drive end and the fan end of the motor housing respectively. Vibration signals are collected by a 16-channel DAT recorder. The vibration signal sampling frequency is f=12kHz. Bearing type 6205-2RS JEM SKF.

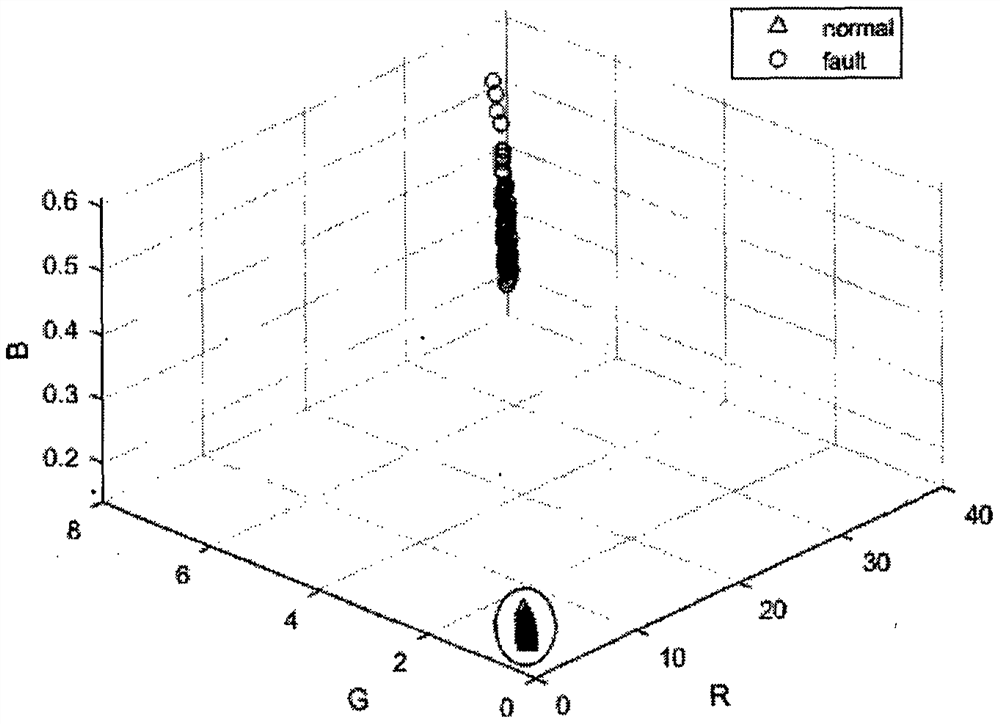

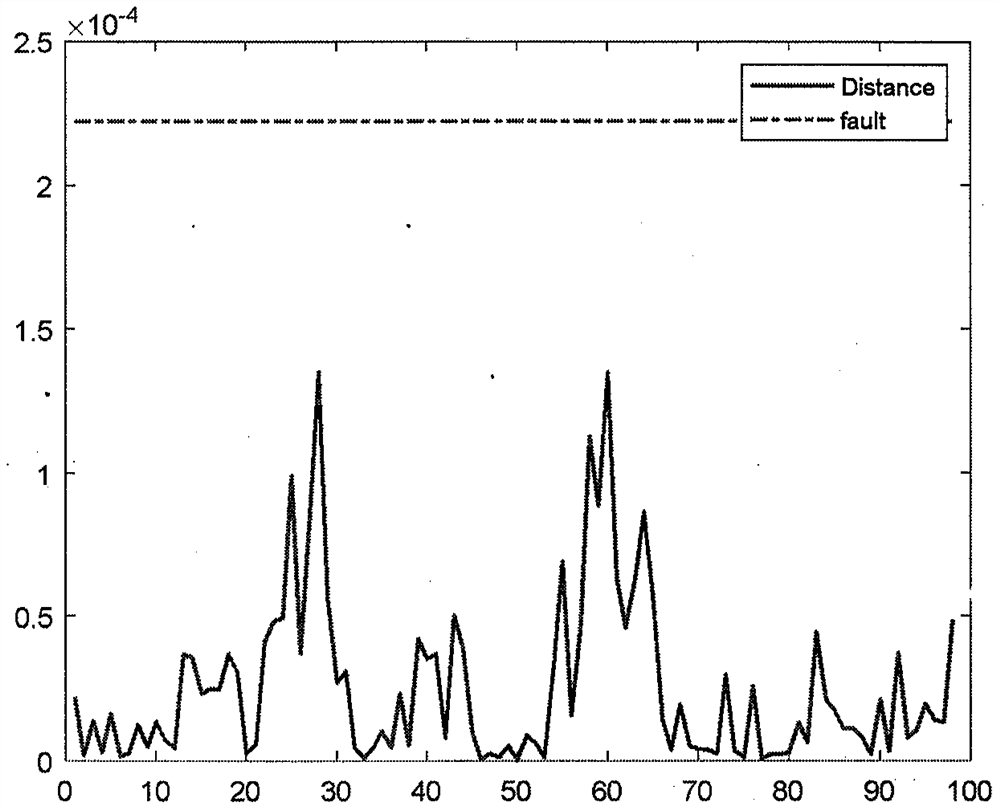

[0044] In this case, select the test data set under normal conditions without load, calculate the RGB-like value, and calculate the hypersphere in the normal state to obtain the center and radius. Then select the test data set of the drive end fault, calculate the RGB-like value, and the distance from the center of the hypersphere in...

Embodiment approach 2

[0066] The data set of the bearing test platform of Case Western Reserve University is used, including normal state Normal, inner ring fault Faultln, rolling ball fault FaultBall, outer ring fault FaultOut, 4 kinds of state data.

[0067] Steps 1 to 3 are the same as steps 1 to 3 in Embodiment 1, and the RGB-like values of the four states are calculated.

[0068] Step 4), for the 4 state data sets, use the support vector data description method to calculate the hypersphere, and get 4 sphere centers and radii. Among them, c1=[3.3931, 0.812, 0.1518] of hypersphere center in normal state, and λ=2, that is, the fault detection threshold is 0.0002223. Inner circle fault state hypersphere center c1=[31.3754, 6.4175, 0.4353], take λ=1, that is, the threshold value is 0.0261. In the fault state of the rolling ball, the hypersphere center c1=[7.0926, 1.2328, 0.1373], and λ=1, that is, the threshold value is 0.0003906. Outer ring fault state hypersphere center c1=[38.6083, 7.7409, 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com