Interface-modified solid garnet type battery and preparation method thereof

A garnet type, interface modification technology, applied in the field of electrochemistry, to achieve the effect of improving contact, improving cycle and rate performance, and reducing interface impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

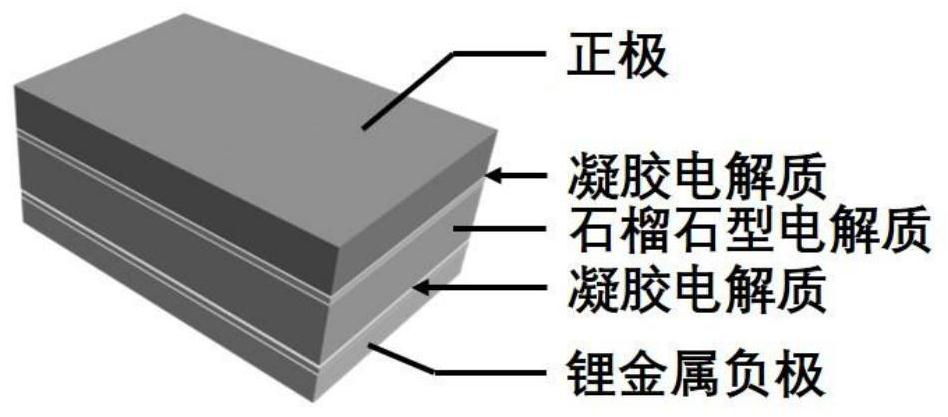

Method used

Image

Examples

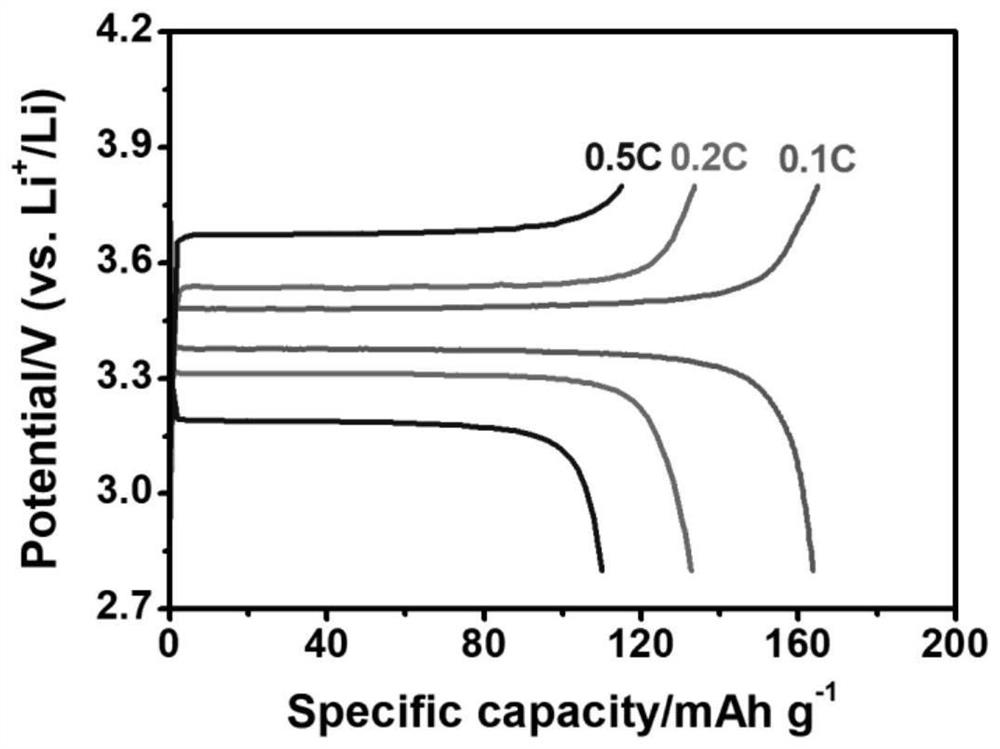

Embodiment 1

[0039] In this example, the preparation process of a solid-state garnet-type battery using an in-situ polymerized gel electrolyte for interface modification includes the following steps:

[0040] (1) Evenly disperse 0.7g of LFP positive electrode powder, 0.15g of PVDF binder and 0.15g of Super P electronic conductivity agent in NMP solvent, and magnetically stir for 2h to obtain positive electrode slurry; apply the positive electrode slurry to the current collector aluminum foil On the above, the positive electrode slurry was dried at 60°C for 48 hours to obtain the positive electrode; then the positive electrode was cut into discs with a diameter of 10mm for later use;

[0041] (2) Mix 1g ETPTA, 5g LB-303 and 0.01g AIBN, and magnetically stir for 3 hours at room temperature to obtain the precursor of the gel electrolyte;

[0042] (3) Apply 1 microliter of the precursor of the gel electrolyte to the Li 6.4 La 3 Zr 1.4 Ta 0.6 o 12 One side of the ceramic electrolyte, and t...

Embodiment 2

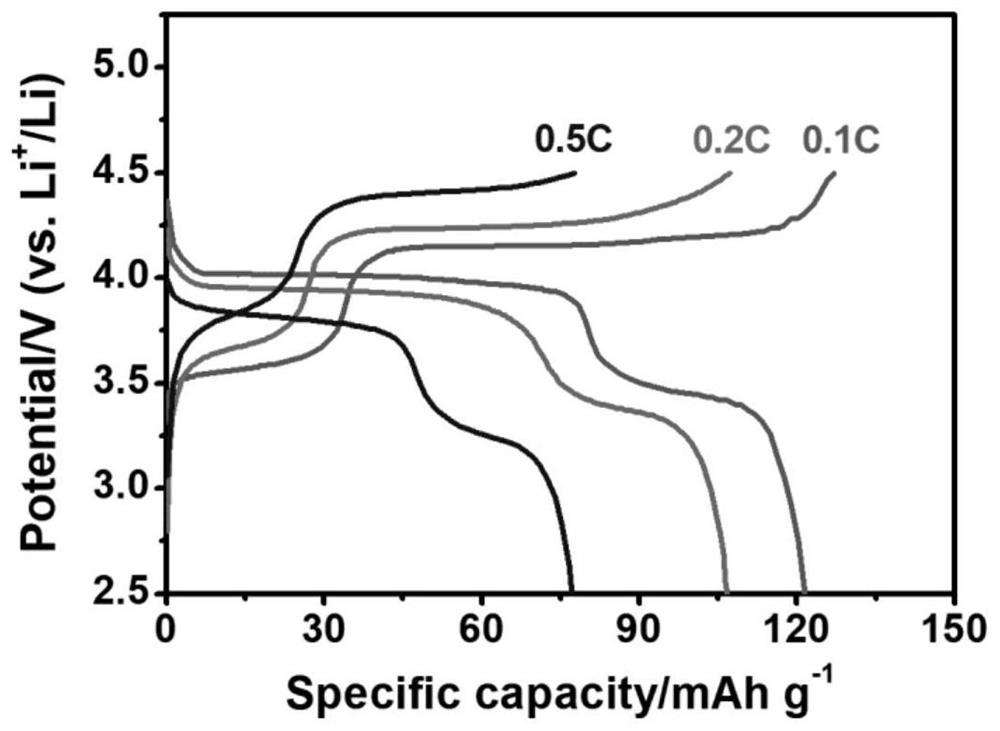

[0048] In this example, the preparation method of lithium manganese iron phosphate-based solid-state garnet battery using in-situ polymer gel electrolyte for interface modification is basically the same as that of Example 1, the difference is that the step (1) of this example is: 0.7g LFMP Positive electrode powder, 0.15g PVDF binder and 0.15g Super P electronic conductivity agent were evenly dispersed in NMP solvent, and magnetically stirred for 2h to obtain positive electrode slurry; the positive electrode slurry was coated on the current collector aluminum foil, and the positive electrode slurry was placed on the After drying at 60° C. for 48 hours, the positive electrode was obtained; and the positive electrode was cut into discs with a diameter of 10 mm for future use.

[0049] image 3 It is the charge-discharge curve of the manganese iron phosphate lithium-based solid-state garnet battery using the in-situ polymer gel electrolyte to modify the interface of the positive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com