Lead raw material and shell separation device for lead-acid battery recycling

A lead-acid battery and separation device technology, which is used in the separation of solids from solids by air flow, solid separation, wet separation, etc. Achieve separation and recovery, improve the effect of separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

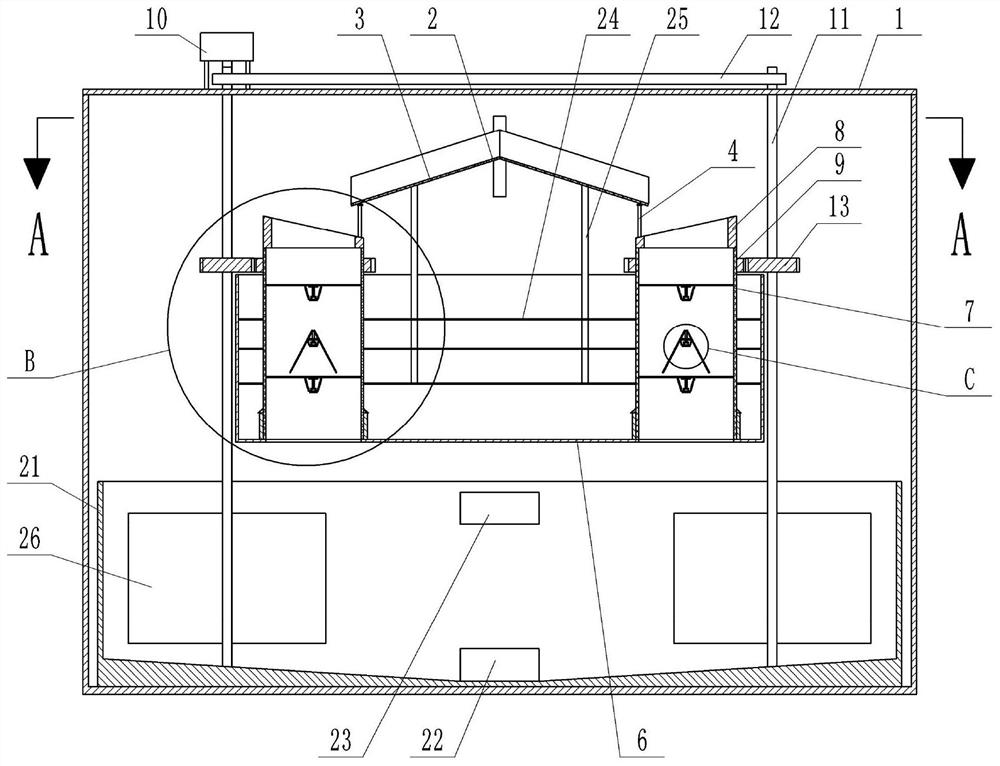

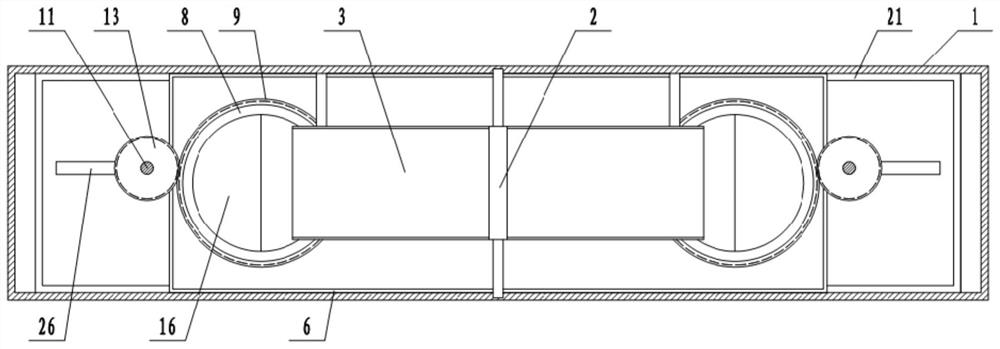

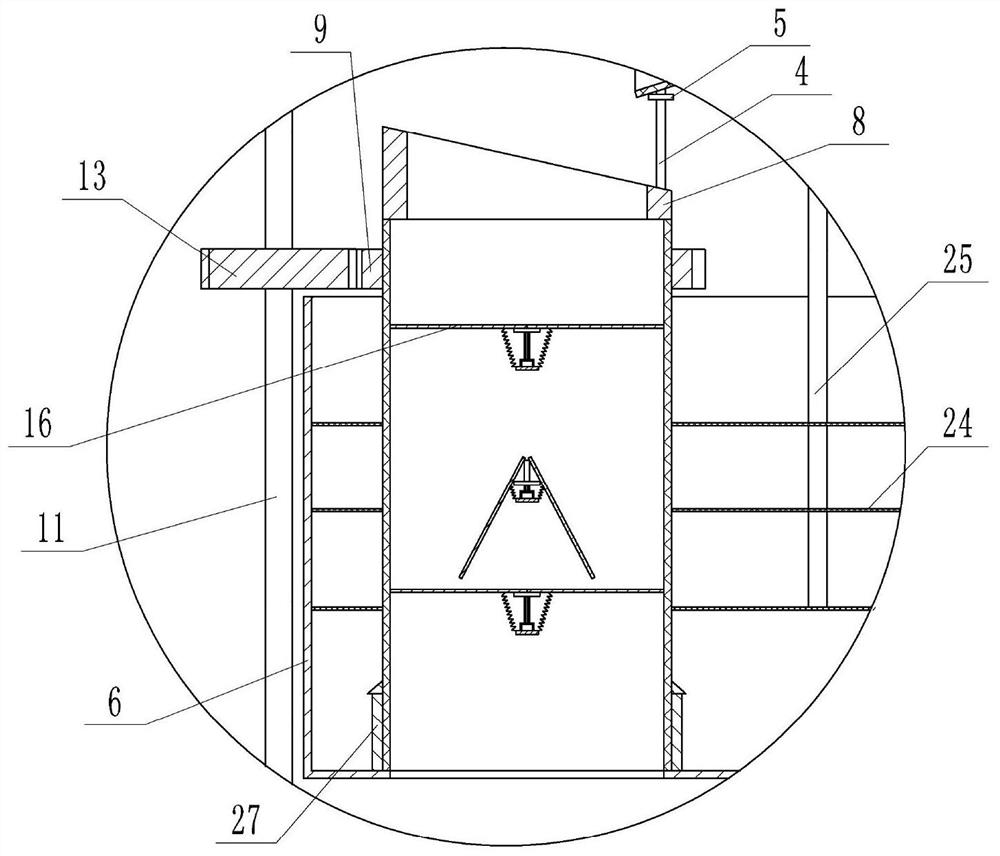

[0038] The device for separating lead raw materials and shells used for recycling lead-acid batteries includes a box body 1, and a feeding port is opened on the upper part of the box body 1, and the feeding port communicates with the output port of the crushing device. There is a material distribution platform 2 below the feed inlet, the material distribution platform 2 is V-shaped, and the material distribution platform 2 is slidably connected to the inner wall of the box body 1, specifically: the front and rear inner walls of the box body 1 are both A chute is provided in the longitudinal direction, and a slide bar is welded on the bottom of the material distribution platform 2, and the two ends of the slide bar are slidably connected in the two chute respectively, thereby guiding the longitudinal movement of the material distribution platform 2. combined with figure 1 And attached figure 2 As shown, the left and right sides of the material distributing platform 2 are weld...

Embodiment 2

[0052] The difference between this embodiment and Embodiment 1 is that the bottoms of the two rotating shafts 11 extend into the flotation cell 21 and are welded with several stirring plates 26 for stirring the separation liquid and allowing the materials to disperse, thereby allowing the It is easier for the shell to float up and separate. The stirring plate 26 extends along the axial direction of the rotating shaft 11 . The stirring plate 26 has a mesh structure, and the length of the stirring plate 26 is not less than the distance from the rotating shaft 11 to the central axis of the drum 7 .

[0053] When the material falls from the bottom of the drum 7 into the flotation tank 21, the rotating shaft 11 continuously drives the separation liquid and the material to move through the stirring plate 26, so that the material falling into the flotation tank 21 is dispersed and the shell is easier to float come up to achieve separation. The length of the agitating plate 26 is not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com