Recycling Lead Raw Material System Using Waste Lead-acid Batteries

A battery recycling and waste lead-acid technology, which is applied in battery recycling, lead-acid batteries, lead-acid battery construction, etc., can solve the problems of easy-to-produce materials, accumulation, and poor separation effect of lead raw materials, so as to achieve separation and recycling, Improve the effect of the separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

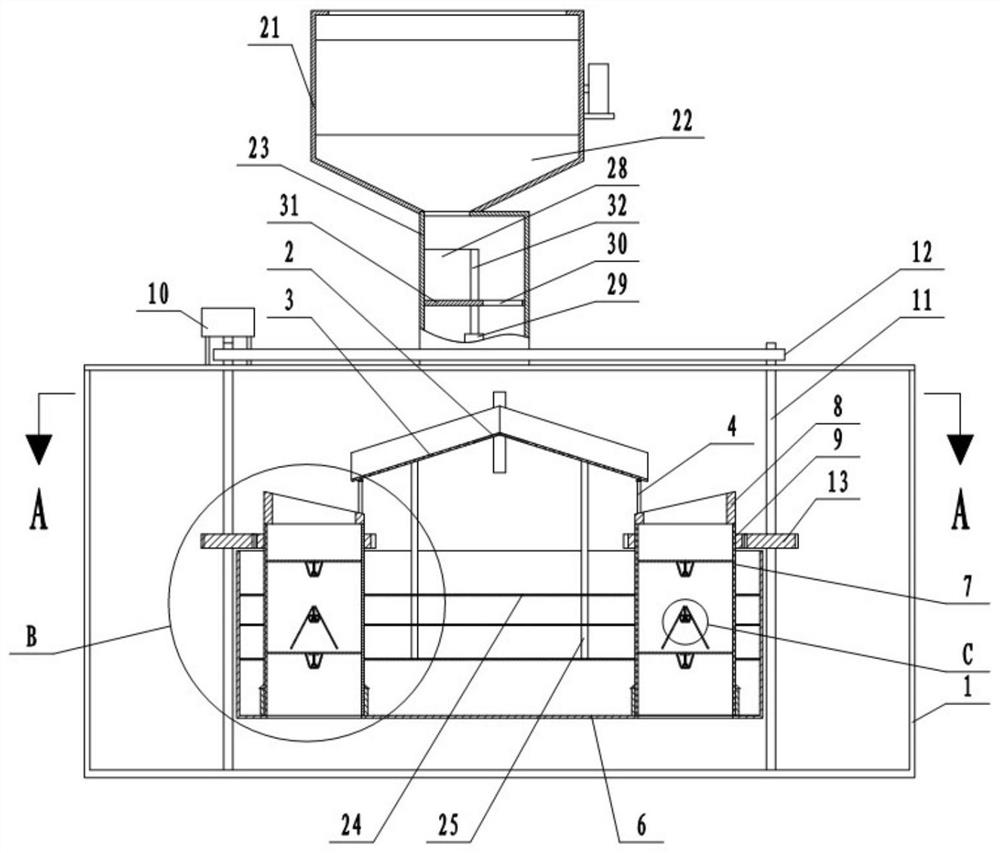

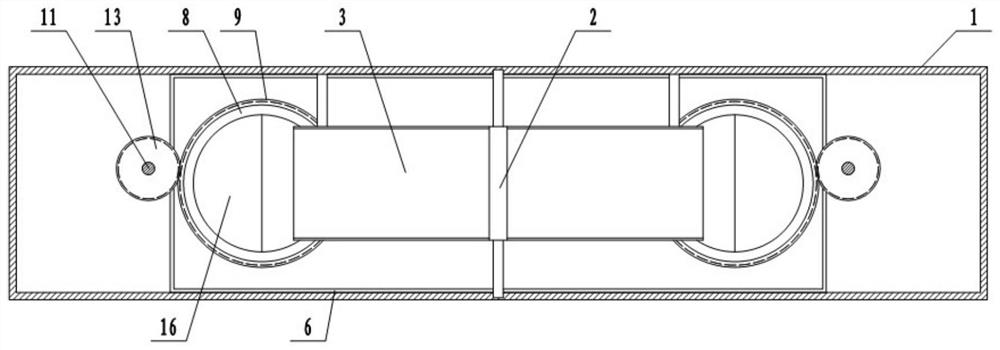

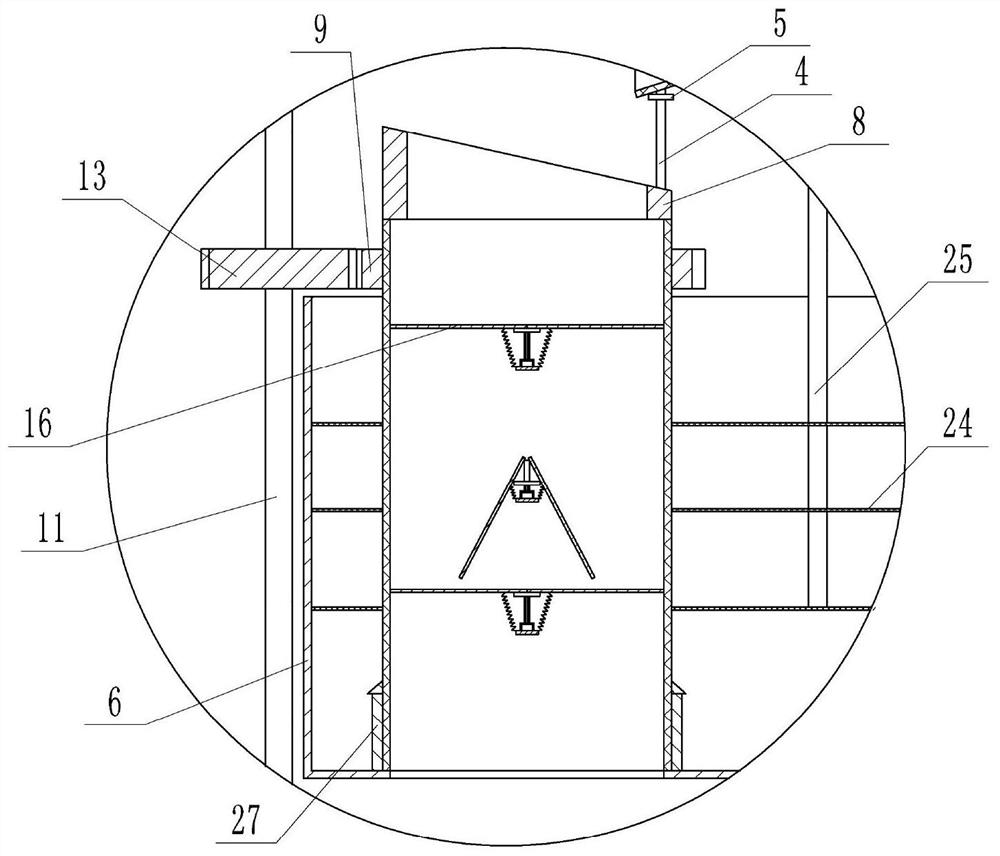

[0037] Utilize waste lead-acid batteries to recover lead raw material system, mainly include crushing device, sorting device, desulfurization treatment device, smelting device and crude lead copper removal device, wherein crushing device includes crushing box 21, is installed in the crushing box 21 and is used for scrap lead Acid battery for crushing the rollers and a drive motor for driving the rollers; the bottom of the crushing box 21 is provided with a material output port 22 . The lead raw material sorting device includes a sorting box 1, and the upper part of the sorting box 1 is provided with a feeding port, and the feeding port communicates with the material output port 22 of the crushing device. There is a material distributing platform 2 below the feed inlet, the material distributing platform 2 is V-shaped, and the material distributing platform 2 is slidably connected to the inner wall of the sorting box 1, specifically: the front and rear inner walls of the sorting...

Embodiment 2

[0049] The difference between this embodiment and Embodiment 1 is that the bottom of the crushing box 21 is provided with an intermittent feeding unit, which is used to intermittently feed the crushed materials into the lead raw material sorting device to reduce the accumulation of materials. probability. The intermittent feeding unit includes a cylinder 23 , the top of which is welded to the bottom of the crushing box 21 , and the bottom of the cylinder 23 is welded or abuts against the top surface of the sorting box 1 . The diameter of the barrel body 23 is larger than the bottom port of the material output port 22 of the crushing box 21 . A fixed plate 31 arranged horizontally is welded in the cylinder body 23, the left side of the fixed plate 31 is located below the material output port 22, and the right side of the fixed plate 31 is provided with a blanking port 30, which is located at the lead raw material point. The top of the feed port of the selection device is oppos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com