High-quality processing technology of glass mold

A glass mold and processing technology, applied in the field of high-quality glass mold processing technology, can solve the problems of long production cycle of process steps, affecting the matching accuracy of glass mold mating surfaces, affecting product scrap rate, etc., to achieve good economic benefits, processing The effect of high precision and increased service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

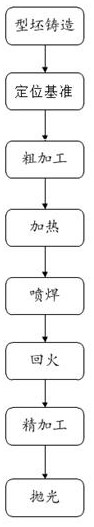

[0024] A high-quality processing technology for a glass mould, comprising the following specific steps:

[0025] a. Blank casting: casting a billet by casting, and then annealing to obtain a glass mold parison;

[0026] b. Positioning reference: Carry out plane processing on the Hough surface of the cast glass mold parison, and take the processed Hough surface as the positioning reference;

[0027] c. Rough machining: the outer surface and inner surface of the glass mold parison are subjected to rough machining;

[0028] d. Heating: heat the glass mold, the heating temperature is 560°C, and the heating time is 0.5h;

[0029] e. Spray welding: Spray welding the outer surface and inner surface of the heated glass mold with tungsten carbide nickel-based powder, and the thickness of the spray welding is 0.3mm;

[0030] f. Tempering: Temper the heated glass mold at a tempering temperature of 320°C

[0031] g. Finishing: After the glass mold is cooled naturally, the mold is finel...

Embodiment 2

[0038] A high-quality processing technology for a glass mould, comprising the following specific steps:

[0039] a. Blank casting: casting a billet by casting, and then annealing to obtain a glass mold parison;

[0040] b. Positioning reference: Carry out plane processing on the Hough surface of the cast glass mold parison, and take the processed Hough surface as the positioning reference;

[0041] c. Rough machining: the outer surface and inner surface of the glass mold parison are subjected to rough machining;

[0042] d. Heating: heat the glass mold, the heating temperature is 665°C, and the heating time is 1h;

[0043] e. Spray welding: Spray welding the outer surface and inner surface of the heated glass mold with tungsten carbide nickel-based powder, and the thickness of the spray welding is 0.5mm;

[0044] f. Tempering: Temper the heated glass mold at a tempering temperature of 415°C

[0045] g. Finishing: After the glass mold is cooled naturally, the mold is finely ...

Embodiment 3

[0052] A high-quality processing technology for a glass mould, comprising the following specific steps:

[0053] a. Blank casting: casting a billet by casting, and then annealing to obtain a glass mold parison;

[0054] b. Positioning reference: Carry out plane processing on the Hough surface of the cast glass mold parison, and take the processed Hough surface as the positioning reference;

[0055] c. Rough machining: the outer surface and inner surface of the glass mold parison are subjected to rough machining;

[0056] d. Heating: heat the glass mold, the heating temperature is 780°C, and the heating time is 1.5h;

[0057] e. Spray welding: Spray welding the outer surface and inner surface of the heated glass mold with tungsten carbide nickel-based powder, and the thickness of the spray welding is 0.8mm;

[0058] f. Tempering: Temper the heated glass mold at a tempering temperature of 480°C

[0059] g. Finishing: After the glass mold is cooled naturally, the mold is finel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com