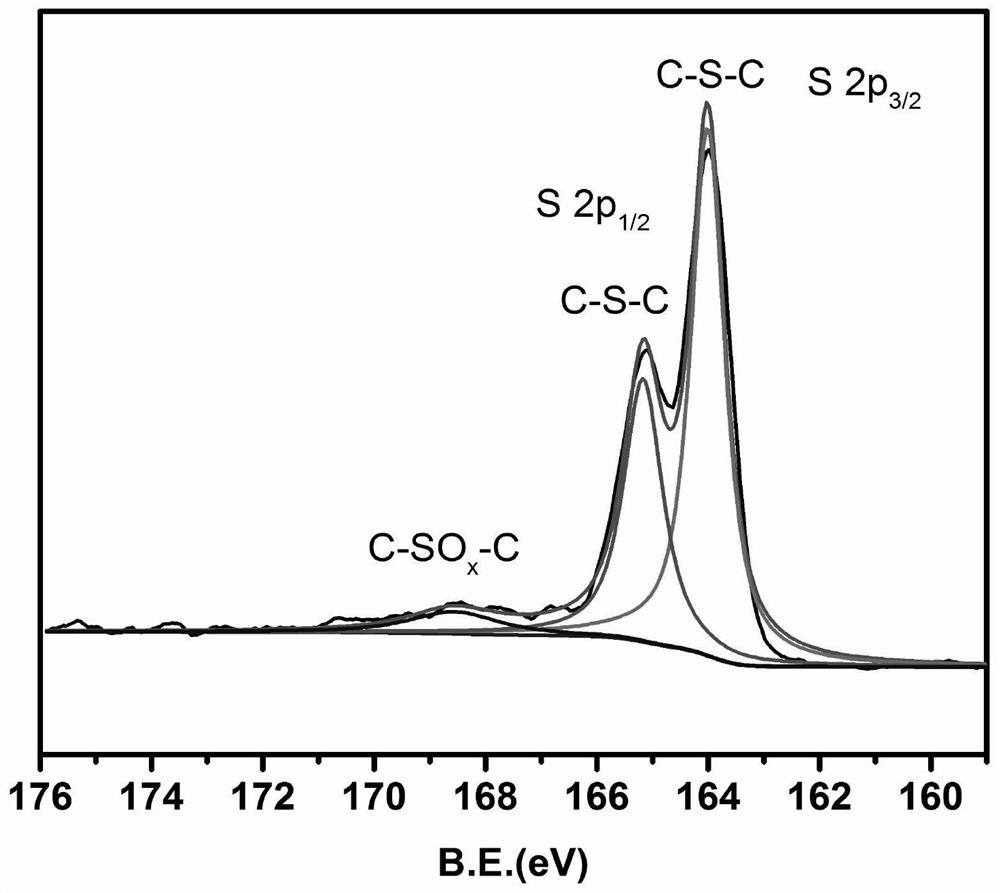

Method for preparing sulfur-doped carbon material from biomass

A biomass, sulfur doping technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problem of no rapid pyrolysis, and achieve the effect of reducing processing time, wide source, and less time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

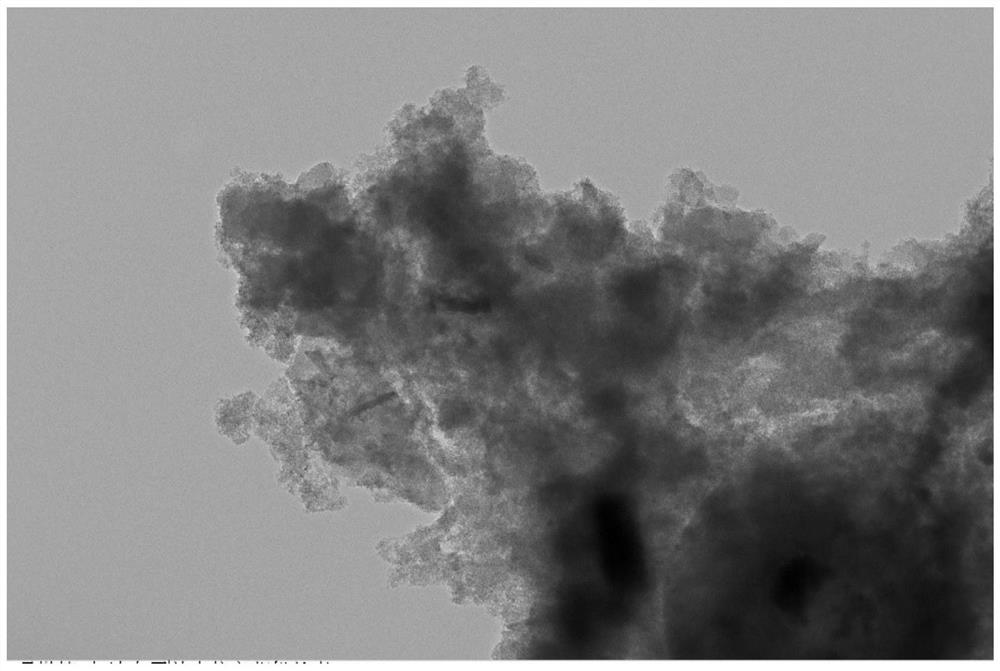

[0057] In this example, four different types of biomass, namely cellulose, glucose, sawdust, and waste paper, were selected for crushing, and 5 g of the above-mentioned biomass particles were weighed for use, and sulfur-doped carbon was prepared according to the following preparation method Material;

[0058] A method for preparing sulfur-doped carbon materials from biomass, comprising the following steps:

[0059] Step 1, crushing the biomass into fine particles;

[0060] Step 2, selecting 5 g of the pulverized biomass particles and mixing them with sulfuric acid solution at a ratio of 1:1 by sulfur / carbon mass ratio to form a homogeneous mixture,

[0061] Step 3, put the mixture into a hydrothermal reaction kettle with a volume of 100ml, seal the reaction kettle and place it in an oven at 200°C for 12 hours;

[0062] Step 4. After the hydrothermal reaction, take out the reaction kettle, and after the reaction kettle is cooled to room temperature, transfer the hydrothermal ...

Embodiment 2

[0068] In this embodiment, the influence of different sulfur sources and acid sources on the properties of boron-doped biomass carbon materials was tested, only the types of sulfur sources and acid sources were changed, and the amount of added acid sources was used to control the pH<3 of the solution, and follow the steps below The preparation method prepares the material;

[0069] A method for preparing sulfur-doped carbon materials from biomass, comprising the following steps:

[0070] Step 1, crushing the sawdust biomass into fine particles;

[0071] Step 2, selecting 5 g of the pulverized biomass particles and mixing them with a sulfuric acid solution at a ratio of 1:1 by sulfur / carbon mass ratio to form a homogeneous mixture;

[0072] Step 3, put the mixture into a hydrothermal reaction kettle with a volume of 100ml, seal the reaction kettle and place it in an oven at 200°C for 12 hours;

[0073] Step 4. After the hydrothermal reaction, take out the reaction kettle, and...

Embodiment 3

[0079] In this example, the influence of different sulfur-carbon ratios on the properties of sulfur-doped carbon materials was tested, only the ratio of sulfur-carbon was changed, and the materials were prepared according to the following preparation method;

[0080] A method for preparing sulfur-doped carbon materials from biomass, comprising the following steps:

[0081] Step 1, crushing the sawdust biomass into fine particles;

[0082] Step 2, selecting 5 g of the pulverized biomass particles and sulfuric acid solution to mix according to the ratio of 0.05:1, 0.2:1, 1:1, 4:1 according to the sulfur / carbon mass ratio to form a uniform mixture;

[0083] Step 3, put the mixture into a hydrothermal reaction kettle with a volume of 100ml, seal the reaction kettle and place it in an oven at 200°C for 12 hours;

[0084] Step 4. After the hydrothermal reaction, take out the reaction kettle, and after the reaction kettle is cooled to room temperature, transfer the hydrothermal prod...

PUM

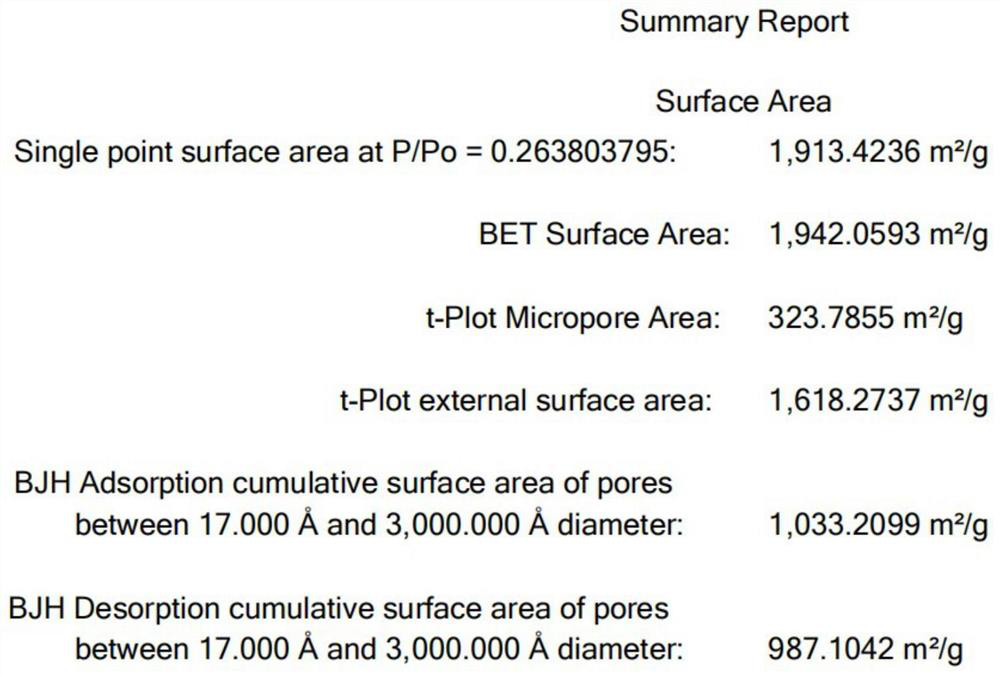

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com