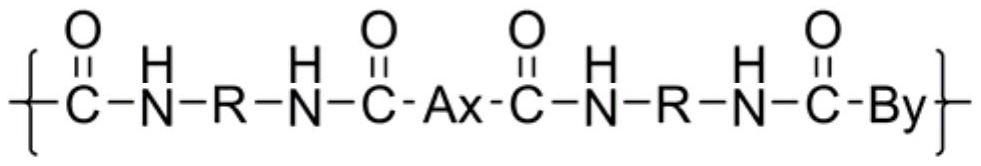

A flame-retardant and toughened bifunctional ionomer additive and its preparation method and application

An ionomer and dual-function technology, which is applied in the field of polymer compound preparation, can solve the problem that it is difficult to effectively improve the flame retardancy and toughening effect of polylactic acid at the same time, and achieve the effect of improving flame retardancy, low investment, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

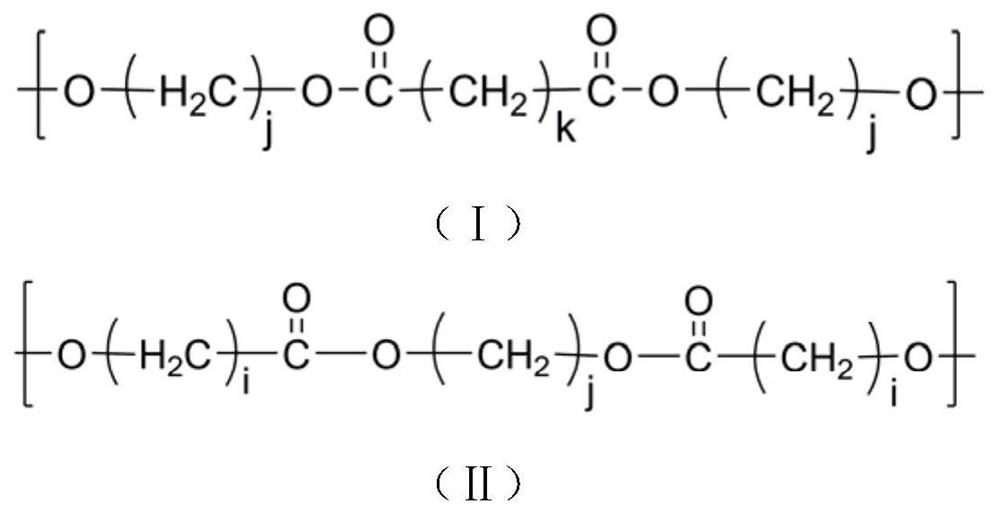

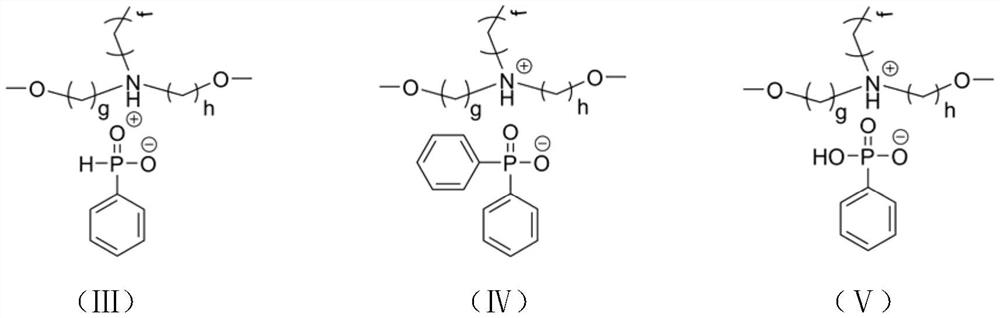

[0039] This embodiment is used to illustrate the preparation method of flame-retardant and toughened bifunctional ionomer additives in the present invention:

[0040] Put about 2000g / mol of hydroxyl-terminated polydecanediol malonate and N-methyldiethanolamine in the reaction device at a mass ratio of 9:1, stir and heat up to its complete melting under the protection of nitrogen, and then add bicyclic Hexylmethane diisocyanate, and the amount of dicyclohexylmethane diisocyanate added is 0.9 times the total hydroxyl molar ratio of hydroxyl-terminated polydecanediol malonate and N-methyldiethanolamine, reacted at 150°C for 0.5 hours to obtain chain extension product. Subsequently, after cooling down to room temperature, dichloromethane was added to the reaction device to dissolve the chain extension product, and then phenylphosphonic acid in an equimolar ratio to N-methyldiethanolamine was added, and an acid-base reaction was carried out at 20°C for 0.5h to obtain the isolated ...

Embodiment 2

[0042] This embodiment is used to illustrate the preparation method of flame-retardant and toughened bifunctional ionomer additives in the present invention:

[0043] Put about 4000g / mol hydroxyl-terminated polybutylene sebacate and N-butyldiethanolamine in the reaction device at a mass ratio of 5:5, stir and heat up to its complete melting under nitrogen protection, then add 1,6-hexamethylene diisocyanate, and the amount of 1,6-hexamethylene diisocyanate added is 1 times the total hydroxyl molar ratio of hydroxyl-terminated polybutylene sebacate and N-butyldiethanolamine , and reacted at 80°C for 1 hour to obtain chain extension products. Subsequently, after cooling down to room temperature, chloroform was added to the reaction device to dissolve the chain extension product, and then phenylphosphinic acid in an equimolar ratio to N-butyldiethanolamine was added, and an acid-base reaction was carried out at 20°C for 5 hours to obtain an ionomer Auxiliary agent, the yield is 9...

Embodiment 3

[0045]This embodiment is used to illustrate the preparation method of flame-retardant and toughened bifunctional ionomer additives in the present invention:

[0046] Put about 6000g / mol hydroxyl-terminated poly(trimethylene sebacate) and N-hexadecyldiethanolamine in the reaction device at a mass ratio of 9:1, stir and heat up to its complete melting under the protection of nitrogen, then add Diphenylmethane diisocyanate, and the addition amount of diphenylmethane diisocyanate is 1 time of the total hydroxyl molar ratio of hydroxyl-terminated polypropylene sebacate and N-hexadecyldiethanolamine, reacted at 160 ° C for 3 hours, and obtained expanded chain product. Then, cool down to room temperature, add dimethyl sulfoxide to the reaction device to dissolve the chain extension product, then add diphenylphosphinic acid in an equimolar ratio to N-hexadecyldiethanolamine, and carry out acid-base reaction at 40°C for 24h , the ionomer additive was obtained with a yield of 96% and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com