Poly(4-hydroxybutyrate) biodegradable packaging film and preparation method thereof

A technology of hydroxybutyrate and packaging film, which is applied in the field of preparation of biodegradable poly packaging film, can solve the problems of complex biological fermentation process, difficult product purification, poor stability, etc., and achieve cost reduction of degradation cycle, strength and Similar toughness and large blow-up ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

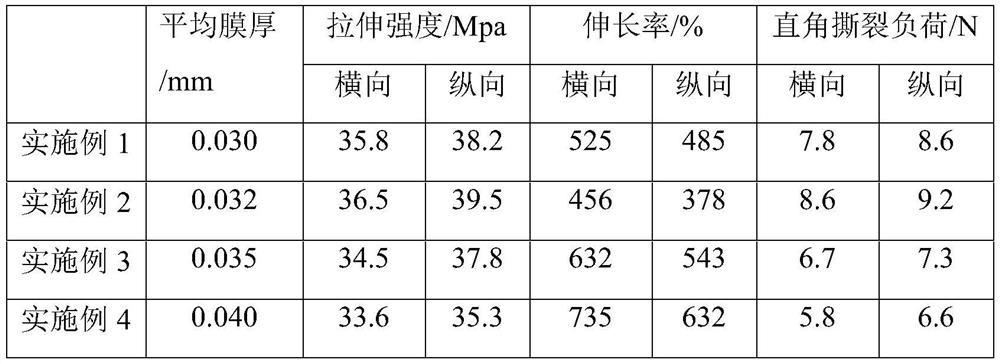

Examples

Embodiment 1

[0034] A biodegradable P4HB packaging film is made of the following raw materials in parts by weight:

[0035] P4HB (molecular weight 80,000, molecular weight 100,000) 70 parts, talc powder 20 parts, TMC200 1 part, erucamide 2 parts, antioxidant 1076 1 part, ADR-4468 2 parts, PEG-4000 3 parts, titanate 1 part of coupling agent.

[0036] The preparation method of above-mentioned biodegradable P4HB packaging film, comprises the following steps:

[0037]Step 1. Weigh a small amount of low molecular weight P4HB, talc powder, PEG-4000, titanate coupling agent, antioxidant 1076, and erucamide according to the formula and put them into a high-speed mixer, stir and blend evenly to obtain a blend The filled masterbatches were prepared by a twin-screw extruder. The processing temperature of the twin-screw extruder is 80°C, 100°C, 100°C, 120°C, 120°C, 120°C, 100°C, the screw speed is 150rpm, the screw combination is high shear, and the cooling water temperature is 7°C.

[0038] Step 2...

Embodiment 2

[0041] A biodegradable P4HB packaging film is made of the following raw materials in parts by weight:

[0042] P4HB (molecular weight 120,000, molecular weight 80,000) 75 parts, chitosan 15 parts, talcum powder 3 parts, EBS 2 parts, antioxidant 1076 1 part, ADR-4468 2 parts, silane coupling agent KH550 2 parts.

[0043] The preparation method of above-mentioned biodegradable P4HB packaging film, comprises the following steps:

[0044] Step 1. Weigh a small amount of low-molecular-weight P4HB, chitosan, KH550, EBS, and antioxidant 1076 according to the formula, put them into a high-speed mixer, stir and blend evenly, and prepare the filled masterbatch from the obtained blend through a twin-screw extruder . The processing temperature of the twin-screw extruder is the same as in the first embodiment, the screw speed is 200 rpm, the screw combination is high shear, and the cooling water temperature is 7°C.

[0045] Step 2. Weigh P4HB according to the formula, fill masterbatch pr...

Embodiment 3

[0048] A biodegradable P4HB packaging film is made of the following raw materials in parts by weight:

[0049] 80 parts of P4HB (molecular weight 150,000, molecular weight 80,000), 10 parts of cellulose, 4 parts of cellulose-g-PCL, 2 parts of ethylene bisstearamide, 1 part of antioxidant 1076, 2 parts of ADR-4468, horse 1 part of anhydride.

[0050] The preparation method of above-mentioned biodegradable P4HB packaging film, comprises the following steps:

[0051] Step 1. Weigh a small amount of P4HB, cellulose, cellulose-g-PCL, ethylene bisstearamide, and antioxidant 1076 according to the formula and put them into a high-speed mixer, stir and blend evenly, and the obtained blend is passed through a twin-screw The extruder prepares the filler masterbatch. The processing temperature of the twin-screw extruder is the same as in Example 1, the screw speed is 150 rpm, the screw combination is high shear, and the cooling water temperature is 7°C.

[0052] Step 2. Weigh P4HB acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com