Iron pot rich in various trace elements and preparation method thereof

A technology of trace elements and iron pots, applied in the direction of special materials for cooking utensils, etc., can solve the problems of waste of selenium raw materials, unsatisfactory selenium recovery rate, etc., and achieve the effect of ensuring the release speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] In the embodiment of the present invention, the preparation method of the iron pot rich in various trace elements includes:

[0061] (1) Using a metal mold with adjustable thickness, pig iron, manganese-selenium alloy, iron-zinc alloy, iron-copper alloy, and iron-molybdenum alloy are mixed and smelted according to the required weight ratio of each layer to obtain molten iron with different alloying elements. After obtaining each layer During the process of making molten iron, ensure uniform mixing and stirring so that each element is evenly distributed in each layer; take out the furnace at 1600°C and cast at 1490°C; cast the molten iron containing each layer in turn, and the casting sequence is: the fourth layer, the second The third floor, the second floor and the first floor;

[0062] After casting the fourth layer, when the fourth layer is cooled to 400-600°C, start casting the third layer;

[0063] After casting the third layer, when both the fourth and third laye...

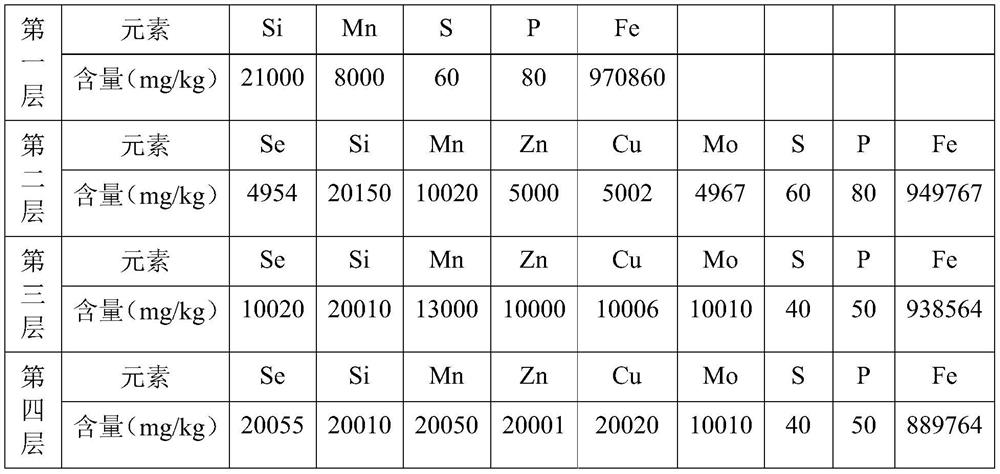

Embodiment 1

[0070] This embodiment provides an iron pan rich in various trace elements.

[0071] The fourth layer uses 428.9 grams of pig iron, 17.0 grams of manganese-selenium alloy, 22.8 grams of iron-zinc alloy, 18.8 grams of iron-copper alloy, and 12.5 grams of iron-molybdenum alloy; the third layer uses 458.2 grams of pig iron, 8.5 grams of manganese-selenium alloy, iron-zinc alloy 11.4 grams of alloy, 9.4 grams of iron-copper alloy, 12.5 grams of iron-molybdenum alloy; the second layer uses 479.2 grams of pig iron, 4.2 grams of manganese-selenium alloy, 5.7 grams of iron-zinc alloy, 4.7 grams of iron-copper alloy, and 6.2 grams of iron-molybdenum alloy; One layer, 500 grams of pig iron.

[0072] That is to say:

[0073] In terms of mass percentage, the composition of the first layer is:

[0074] C: 3.25%-3.35%, Si: 2.1%-2.4%, Mn: 0.6%-0.8%, S≤0.12%, P≤0.15%, the balance is Fe;

[0075] In terms of mass percentage, the composition of the second layer is:

[0076] C: 3.1148%-3.210...

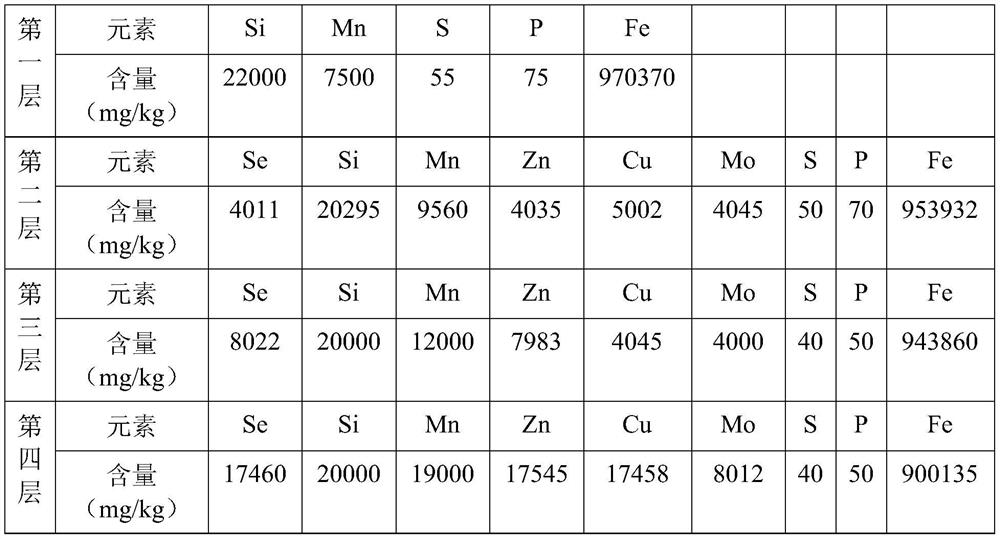

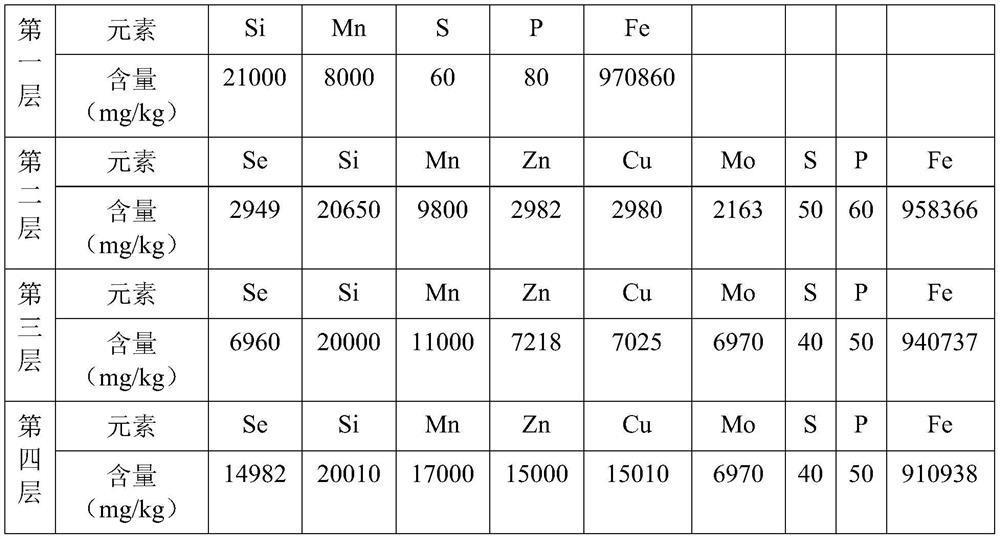

Embodiment 2

[0082] This embodiment provides an iron pan rich in various trace elements.

[0083] The fourth layer uses 438.8 grams of pig iron, 14.8 grams of manganese-selenium alloy, 20.0 grams of iron-zinc alloy, 16.4 grams of iron-copper alloy, and 10.0 grams of iron-molybdenum alloy; the third layer uses 466.6 grams of pig iron, 6.8 grams of manganese-selenium alloy, iron-zinc alloy 9.1 grams of alloy, 7.5 grams of iron-copper alloy, and 10.0 grams of iron-molybdenum alloy; the second layer adopts 483.2 grams of pig iron, 3.4 grams of manganese-selenium alloy, 4.6 grams of iron-zinc alloy, 3.8 grams of iron-copper alloy, and 5.0 grams of iron-molybdenum alloy; One layer, 500 grams of pig iron.

[0084] That is to say:

[0085] In terms of mass percentage, the composition of the first layer is:

[0086] C: 3.25%-3.35%, Si: 2.1%-2.4%, Mn: 0.6%-0.8%, S≤0.12%, P≤0.15%, the balance is Fe;

[0087] In terms of mass percentage, the composition of the second layer is:

[0088] C: 3.1408%-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com