Anode active material for secondary battery, anode comprising same, and method for manufacturing same

A negative electrode active material, secondary battery technology, applied in secondary batteries, battery electrodes, active material electrodes, etc., can solve the problems of poor cyclic expansion and fast charging performance, weakening of electrode mechanical strength, electrode expansion, etc., to improve The effect of the cycle feature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

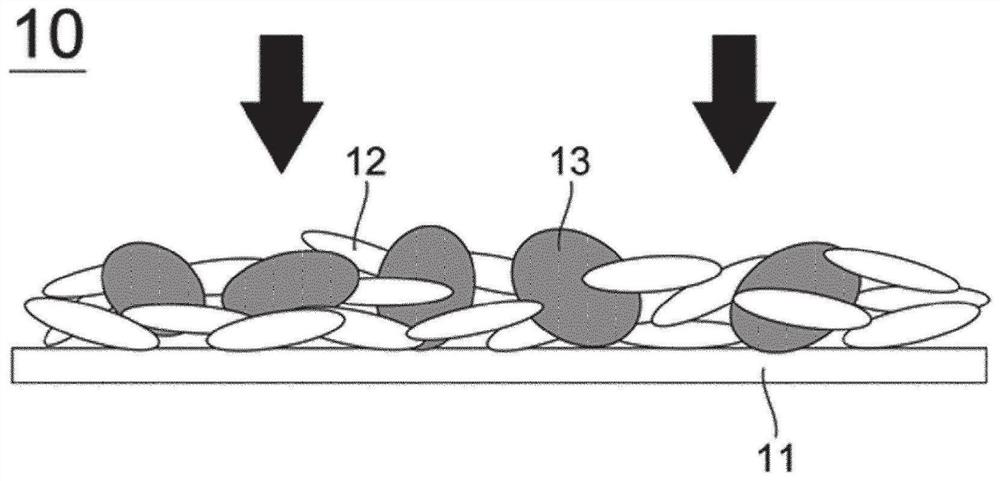

Image

Examples

Embodiment 1

[0104] Preparation of negative electrode

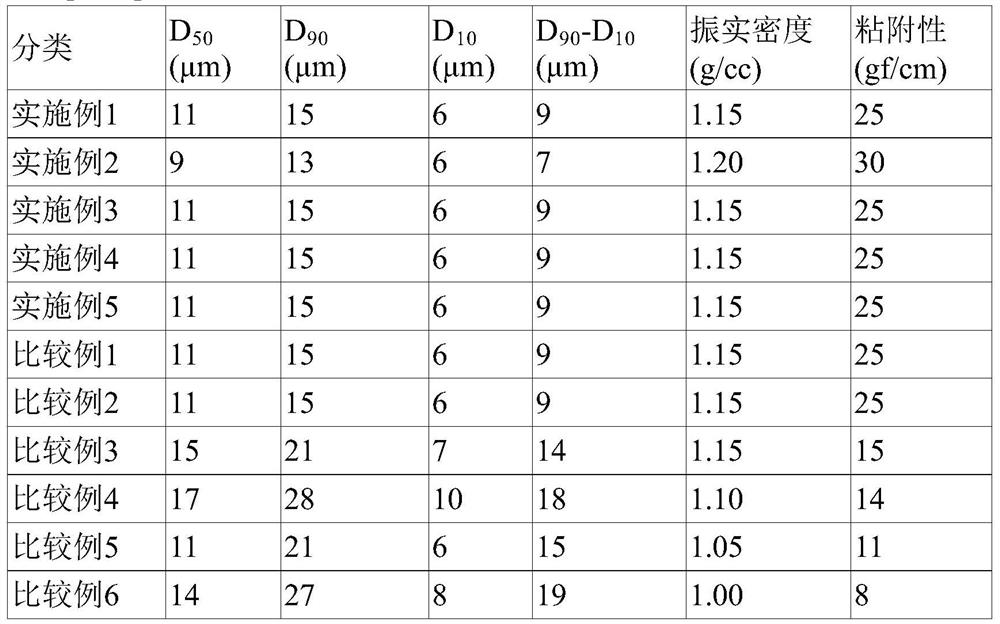

[0105] The negative electrode was prepared using a negative electrode active material containing 80% by weight of artificial graphite and 20% by weight of spherical natural graphite. Specifically, natural graphite with a small particle size and uniform particle size is used for the negative electrode active material, and the natural graphite has a particle size distribution (D 50 ) is 11μm, D 90 5μm, D 10 6μm and D 90 -D 10 The average particle size is 9 μm. In addition, the tap density of spherical natural graphite was 1.15 g / cc (measured by performing 2000 taps using a tap density measuring instrument (TAP-2S manufactured by LOGAN)), and the electrode adhesion after roll pressing was 25gf / cm. As artificial graphite, the average particle size (D 50 ) is flake artificial graphite of 15.5 μm (tap density: 0.90 g / cc).

[0106] Natural graphite used as negative electrode active material, SuperC65 used as conductive material, st...

Embodiment 2

[0112] Preparation of negative electrode

[0113] The negative electrode was prepared using a negative electrode active material containing 80% by weight of artificial graphite and 20% by weight of spherical natural graphite. Specifically, natural graphite with a small particle size and uniform particle size is used for the negative electrode active material, and the natural graphite has a particle size distribution (D 50 ) is 9μm, D 90 13μm, D 10 6μm and D 90 -D 10 The average particle size is 7 μm. In addition, the tap density of the spherical natural graphite was 1.20 g / cc, so the electrode adhesion after rolling was 30 gf / cm. As artificial graphite, the average particle size (D 50 ) is flake artificial graphite (tap density: 0.93 g / cc) of 14.5 μm.

[0114] Natural graphite used as negative electrode active material, SuperC65 used as conductive material, styrene butadiene high component (SBR) used as binder and carboxymethyl cellulose (CMC) used as thickener were r...

Embodiment 3

[0119] Except using the negative electrode active material containing the artificial graphite of 85% by weight of Example 1 and the spherical natural graphite of 15% by weight of Example 1, negative electrodes and batteries (coin-type full cells and full batteries) were prepared in the same manner as in Example 1 half battery).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com