Titanium-based heterogeneous amination composite catalyst as well as preparation method and application thereof

一种复合催化剂、催化剂载体的技术,应用在催化剂活化/制备、物理/化学过程催化剂、化学仪器和方法等方向,能够解决操作过程复杂、操作控制困难、效率低等问题,达到优化反应历程、比表面积大、防止漏流的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

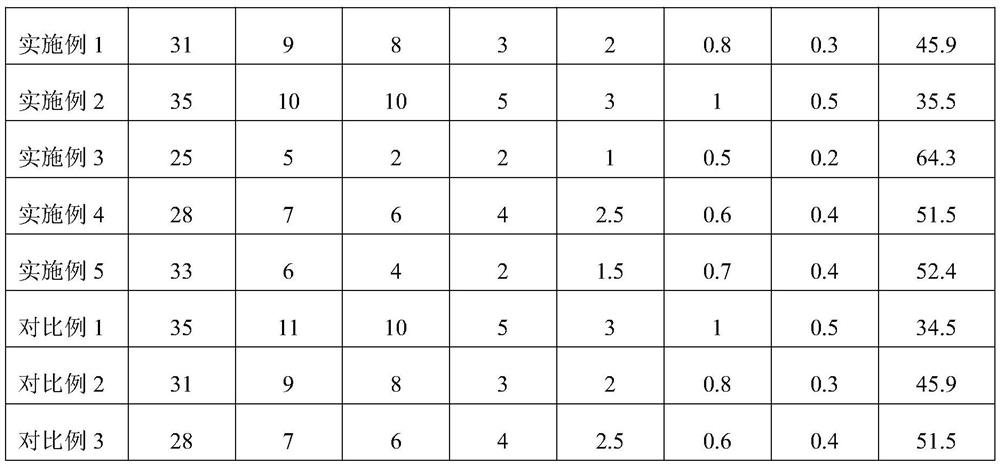

Embodiment 1

[0107] Embodiment 1 of the present invention discloses a titanium-based heterogeneous amination composite catalyst, which is prepared by the following method:

[0108] (1) Al(NO 3 ) 3 9H 2 O, Mo(NO 3 ) 3 ·5H 2 O, Ni(NO 3 ) 2 ·6H 2 Dissolve O in deionized water, prepare a 0.5mol / L solution, raise the temperature to 60°C, add the carrier and stir well, gradually add 0.02mol / L dilute nitric acid or dilute sulfuric acid dropwise during the stirring process, mix well, and control the pH value 5 to 6, and gradually lowered to room temperature to obtain mixed solution A; Al(NO 3 ) 3 9H 2 O, Mo(NO 3 ) 3 ·5H 2 O, Ni(NO 3 ) 2 ·6H 2 The molar ratio of Al, Mo and Ni in O is 1:1.2:0.5;

[0109] (2) put C 16 h 36 o 4 Dissolve Si in 0.02mol / L dilute nitric acid or dilute sulfuric acid, control the temperature at 20-30°C, add C 16 h 36 o 4 Ti, stir, add ammonia water dropwise, control the pH value to 6.5~7.5, continue to stir for 10h, move to the hydration heat reaction...

Embodiment 2

[0113] Embodiment 2 of the present invention discloses a titanium-based heterogeneous amination composite catalyst, which is prepared by the following method:

[0114] (1) Al(NO 3 ) 3 9H 2 O, Mo(NO 3 ) 3 ·5H 2 Dissolve O in deionized water, prepare a 1mol / L solution, raise the temperature to 60-80°C, add the carrier and stir well, gradually add 0.5mol / L dilute nitric acid or dilute sulfuric acid dropwise during the stirring process, mix well, and control the pH The value is 5-6, gradually lowered to room temperature, and mixed solution A is obtained; Al(NO 3 ) 3 9H 2 O, Mo(NO 3 ) 3 ·5H 2 The molar ratio between Al and Mo components in O is 1:0.9;

[0115] (2) put C 16 h 36 o 4 Dissolve Si in 0.02mol / L dilute nitric acid or dilute sulfuric acid, control the temperature at 20-30°C, add C 16 h 36 o 4 Ti, stir, add ammonia water dropwise, control the pH value to 6.5~7.5, continue to stir for 15h, move to the hydration heat reaction kettle and react at 200°C for 24...

Embodiment 3

[0119] Embodiment 3 of the present invention discloses a titanium-based heterogeneous amination composite catalyst, which is prepared by the following method:

[0120] (1) Al(NO 3 ) 3 9H 2 O, Mo(NO 3 ) 3 ·5H 2 O, H 2 PtC l6 ·6H 2 Dissolve O in deionized water, prepare a 0.8mol / L solution, raise the temperature to 70°C, add the carrier and stir well, gradually add 0.3mol / L dilute nitric acid or dilute sulfuric acid dropwise during the stirring process, mix well, and control the pH value 5 to 6, and gradually lowered to room temperature to obtain mixed solution A; Al(NO 3 ) 3 9H 2 O, Mo(NO 3 ) 3 ·5H 2 O, H 2 PtC l6 ·6H 2 The molar ratio of Al, Mo and Pt in O is 1:1.1:0.05;

[0121] (2) put C 16 h 36 o 4 Dissolve Si in 0.02mol / L dilute nitric acid or dilute sulfuric acid, control the temperature at 20-30°C, add C 16 h 36 o 4 Ti, stir, add ammonia water dropwise, control the pH value to 6.5~7.5, continue to stir for 12h, move to the hydration heat reaction k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com