N-methyl pyrrolidone for liquid crystal display panel and production process thereof

A technology of methylpyrrolidone and liquid crystal panels, applied in the field of N-methylpyrrolidone for liquid crystal panels and its production process, can solve the problems of difficult operation and control, large waste of materials, low efficiency, etc. Facilitate the control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

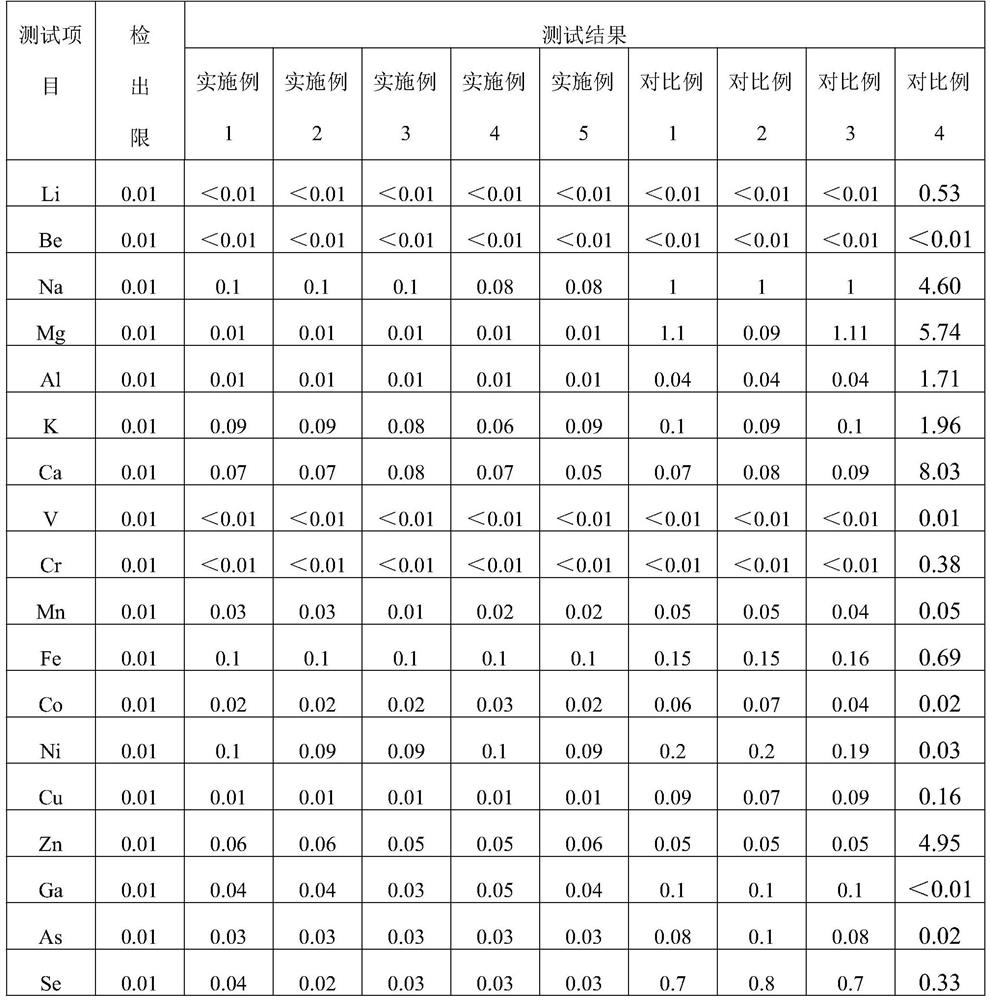

Embodiment 1

[0097] A kind of production technology of N-methylpyrrolidone for liquid crystal panel, comprises the following steps:

[0098] 1. Reaction section: including two-step reaction.

[0099]The first step of amination reaction: First, inject monomethylamine and γ-butyrolactone with a molar ratio of 1.2:1 into the mixing tank respectively by the feed pump, control the stirring preheating temperature at 30°C, stir for 5 minutes, and carry out another Preheating, the preheating temperature is 120°C, and then pumped into a fixed-bed reactor filled with catalyst for amination reaction through a metering pump, the reaction temperature is 200°C, the reaction pressure is 5MPa; the liquid hourly space velocity is 0.5h -1 , to obtain N-methylpyrrolidone crude liquid, the crude liquid is discharged through the material outlet of the reactor, and the content of gamma-butyrolactone in the crude liquid discharged through the discharge port is controlled to be less than or equal to 0.01%;

[01...

Embodiment 2

[0107] A kind of production technology of N-methylpyrrolidone for liquid crystal panel, comprises the following steps:

[0108] 1. Reaction section: including two-step reaction.

[0109] The first step of amination reaction: First, inject monomethylamine and γ-butyrolactone with a molar ratio of 1.3:1 into the mixing tank respectively by the feed pump, control the stirring preheating temperature at 35°C, stir for 8 minutes, and carry out another Preheating, the preheating temperature is 160°C, and then pumped into a fixed bed reactor filled with catalyst for amination reaction through a metering pump, the reaction temperature is 230°C, the reaction pressure is 5.5MPa; the liquid hourly space velocity is 5h -1 , to obtain N-methylpyrrolidone crude liquid, the crude liquid is discharged through the material outlet of the reactor, and the content of gamma-butyrolactone in the crude liquid discharged through the discharge port is controlled to be less than or equal to 0.01%;

[0...

Embodiment 3

[0117] A kind of production technology of N-methylpyrrolidone for liquid crystal panel, comprises the following steps:

[0118] 1. Reaction section: including two-step reaction.

[0119]The first step of amination reaction: First, inject monomethylamine and γ-butyrolactone with a molar ratio of 1.5:1 into the mixing tank by the feed pump, control the stirring preheating temperature at 40°C, stir for 10 minutes, and carry out another Preheating, the preheating temperature is 200°C, and then pumped into a fixed-bed reactor filled with catalyst for amination reaction through a metering pump, the reaction temperature is 260°C, the reaction pressure is 6MPa; the liquid hourly space velocity is 10h -1 , to obtain N-methylpyrrolidone crude liquid, the crude liquid is discharged through the material outlet of the reactor, and the content of gamma-butyrolactone in the crude liquid discharged through the discharge port is controlled to be less than or equal to 0.01%;

[0120] The secon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voidage | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com