Method for preparing cadmium-based alloy nanomaterials

A nanomaterial, cadmium-based alloy technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., to achieve mild conditions, wide application value, and precise and controllable components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

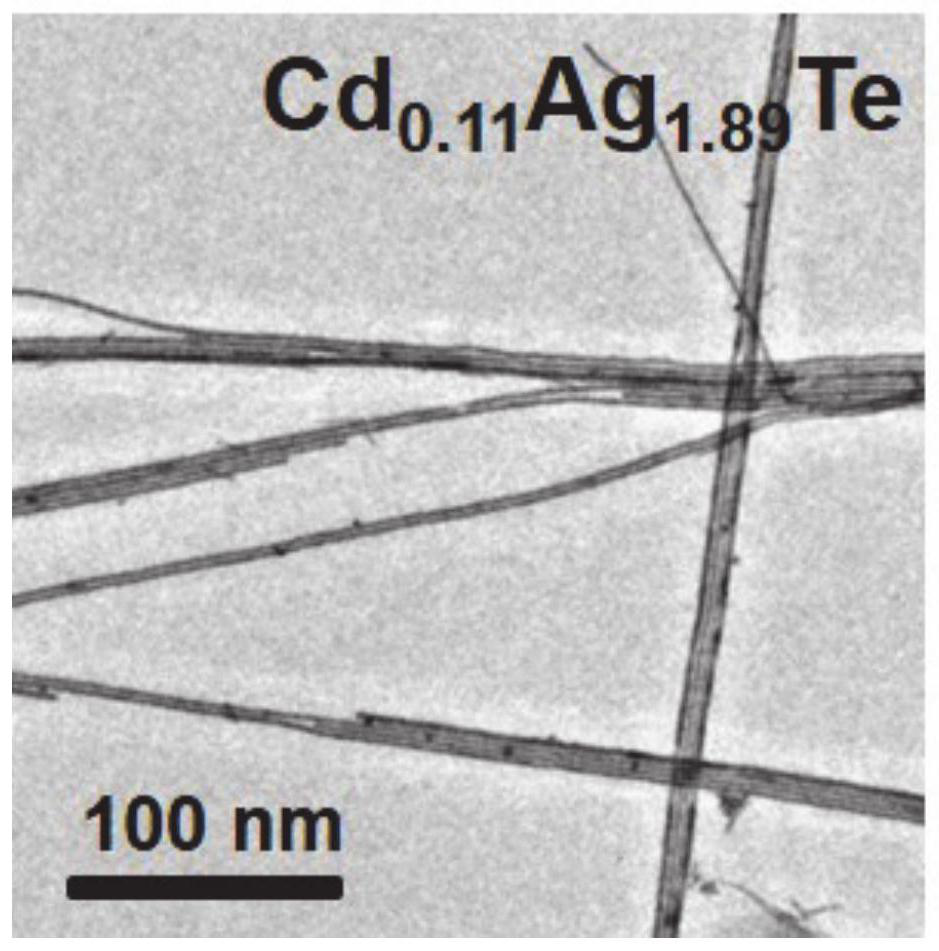

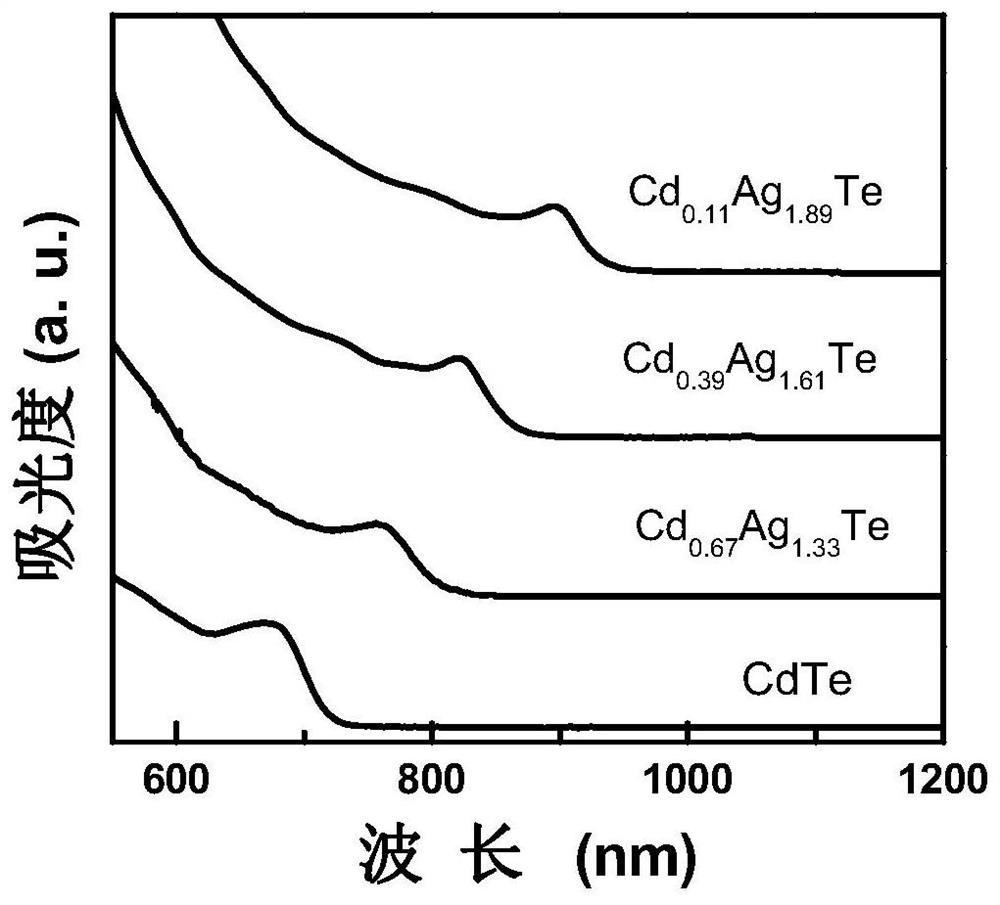

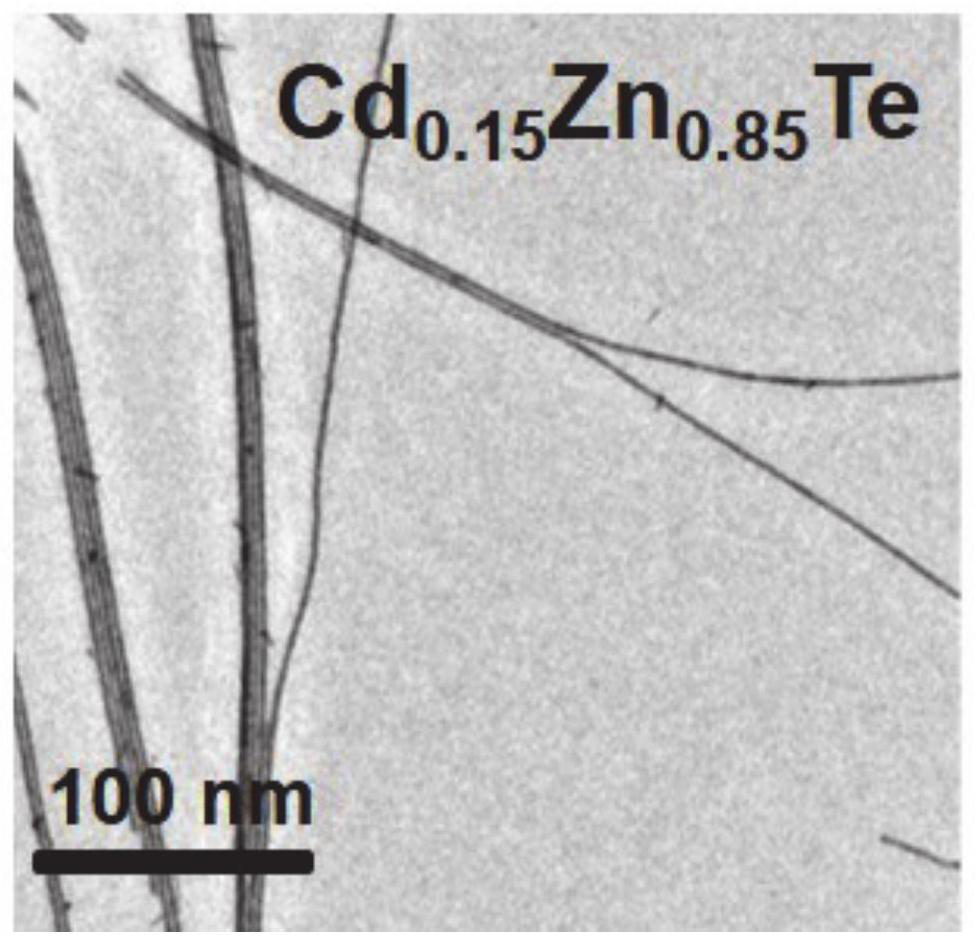

[0127] Cd x m 2 / m-x The preparation of Te alloy semiconductor nanowires, the preparation method comprises the following steps:

[0128] 1) Dissolving the alcohol-soluble CdTe nanowire powder in polar solvent I, under the protection of an inert gas, stirred until clear to obtain an alcohol-soluble CdTe nanowire solution. The polar solvent environment is ethanol, ethylene glycol, N,N-dimethylformamide or dimethyl sulfoxide. The ratio of the alcohol-soluble CdTe nanowires to the polar solvent is 1:2-5.

[0129] 2) Dissolving M-doped metal ions in polar solvent I, under the protection of an inert gas, stirred until clear to obtain M-doped metal ion solutions with different molar concentrations. Wherein, the M-doped metal ions include: one of Ag, Pb, Zn, Ge, Sn, Sb, Bi, Cu, Mn, Eu, Sr, In, Tl and other metal ions. When doping metal ions (Pb, Zn, Ge, Sr, In) in the organic polar solvent and the cadmium ion binding energy in the CdTe nanowire are larger, use organic phosphorus r...

Embodiment 1

[0134] The preparation of embodiment 1 alcohol-soluble CdTe nanowires

[0135] 1) According to the method of the authorized Chinese invention patent (patent number: 201110050390.X), an oil-soluble CdTe nanowire with a diameter of about 7 nm and a length of more than 1 μm was prepared.

[0136] 2) Dilute the above-mentioned oil-soluble CdTe nanowires with toluene, add a mixture of acetone and methanol (the volume ratio of the quality of the nanowires to the mixture of acetone and methanol is 20mg / mL) to precipitate the nanowires, and centrifuge at 7000rpm*3min Finally, the supernatant was discarded to obtain oil-soluble nanowire precipitates, and the above cleaning process was repeated three times to obtain high-purity oil-soluble nanowire materials. Finally, the nanowire precipitates were vacuum-dried at 60°C and ground to obtain oil-soluble nanowire thread powder.

[0137] 3) Blend 100mg of oil-soluble CdTe nanowire powder with 2mL of mercaptohexanol and 15mL of organic polar ...

Embodiment 2

[0138] The preparation of embodiment 2 alcohol-soluble CdTe nanowires

[0139] The difference from Example 1 is that 80 mg of oil-soluble CdTe nanowire powder is blended with 6 mL of mercaptohexanol and 10 mL of polar solvent into a three-necked flask and continuously stirred to form a suspension, and the reaction temperature is controlled at 10 °C and The reaction time is 50min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com