Environment-friendly ink for carton printing and preparation process thereof

A carton printing and environment-friendly technology, applied in the field of environment-friendly ink and its preparation technology, can solve the problems of accelerated ink surface oxidation-reduction reaction, poor ink printing effect, decreased ink adsorption capacity, etc., so as to improve the ink transfer performance, improve the The effect of improving the finish and ink adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

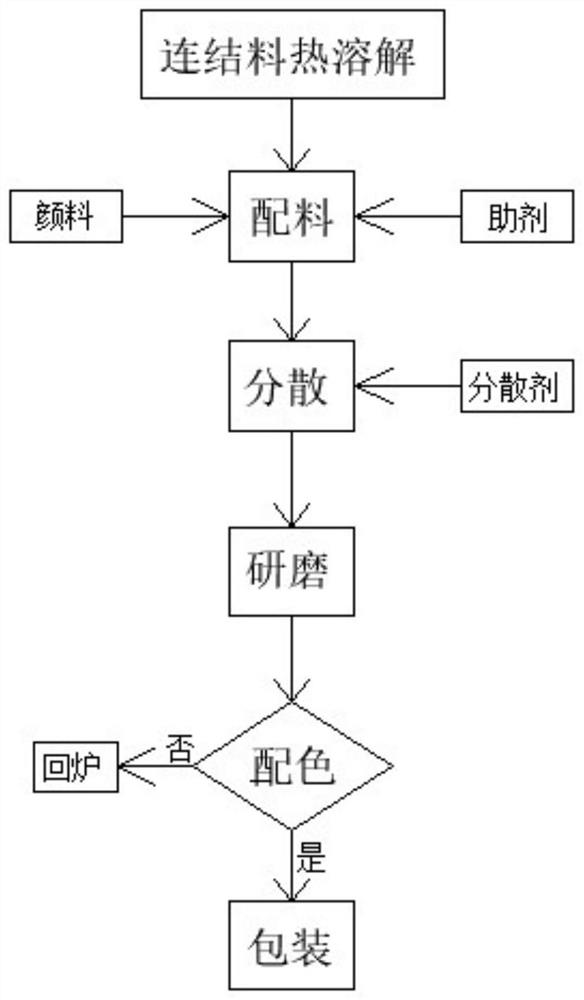

Image

Examples

Embodiment 1

[0025] A preparation process for an environmentally friendly printing ink for carton printing, comprising the steps of:

[0026] Step 1: Select 60 equal parts of synthetic resin and isopropanol and put them into the reaction furnace, heat the reaction furnace, and ensure that the temperature inside the reaction furnace is kept at 50 ° C, and conduct the material in the reaction furnace Stir, thoroughly dissolve and mix the added synthetic resin and isopropanol, and control the heating and dissolving time within 2 to 3 hours. At this time, the mixed solution A is obtained;

[0027] Step 2: Select 15 equal parts of aluminum hydroxide for grinding, and make it into aluminum hydroxide powder state, select 10 parts of phthalocyanine pigments, 13 parts of linseed oil, 3 parts of organic reducing agent and antioxidant, 5 parts of 1 part of cornstarch, 8 parts of synthetic wax, 3 parts of tea dry, 10 parts of calcium sulfate and 1 part of phosphite are added together in the reaction f...

Embodiment 2

[0033] A preparation process for an environmentally friendly printing ink for carton printing, comprising the steps of:

[0034] Step 1: Select 65 equal parts of synthetic resin and isopropanol and put them into the reaction furnace, heat the reaction furnace, and ensure that the temperature inside the reaction furnace is kept at 50°C, and heat the materials in the reaction furnace Stir, thoroughly dissolve and mix the added synthetic resin and isopropanol, and control the heating and dissolving time within 2 to 3 hours. At this time, the mixed solution A is obtained;

[0035]Step 2: Select 18 equal parts of aluminum hydroxide for grinding, and make it into aluminum hydroxide powder state, select 13 parts of phthalocyanine pigments, 17 parts of linseed oil, 4 parts of organic reducing agent and antioxidant, 8 parts of 1 part of cornstarch, 9 parts of synthetic wax, 4 parts of tea dry, 13 parts of calcium sulfate and 1.5 parts of phosphite are added together in the reaction fur...

Embodiment 3

[0041] A preparation process for an environmentally friendly printing ink for carton printing, comprising the steps of:

[0042] Step 1: Select 70 equal parts of synthetic resin and isopropanol and put them into the reaction furnace, heat the reaction furnace, and ensure that the temperature inside the reaction furnace is kept at 50°C, and heat the materials in the reaction furnace Stir, thoroughly dissolve and mix the added synthetic resin and isopropanol, and control the heating and dissolving time within 2 to 3 hours. At this time, the mixed solution A is obtained;

[0043] Step 2: Select 20 equal parts of aluminum hydroxide for grinding, make it into aluminum hydroxide powder state, select 15 parts of phthalocyanine pigments, 20 parts of linseed oil, 5 parts of organic reducing agent and antioxidant, 10 parts of 1 part of cornstarch, 10 parts of synthetic wax, 5 parts of tea cumin, 15 parts of calcium sulfate and 2 parts of phosphite are added together in the reaction furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com