Device and method for aligning optical axis of collimator with optical axis of optical mechanical system in stray light test

A technology of collimating light pipe and aligning device, which is applied in the directions of measuring device, optical instrument testing, testing optical performance, etc., can solve the problems of low efficiency of optical axis method, complicated device structure, difficult operation, etc., and achieves low development cost, Small size and simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with accompanying drawing.

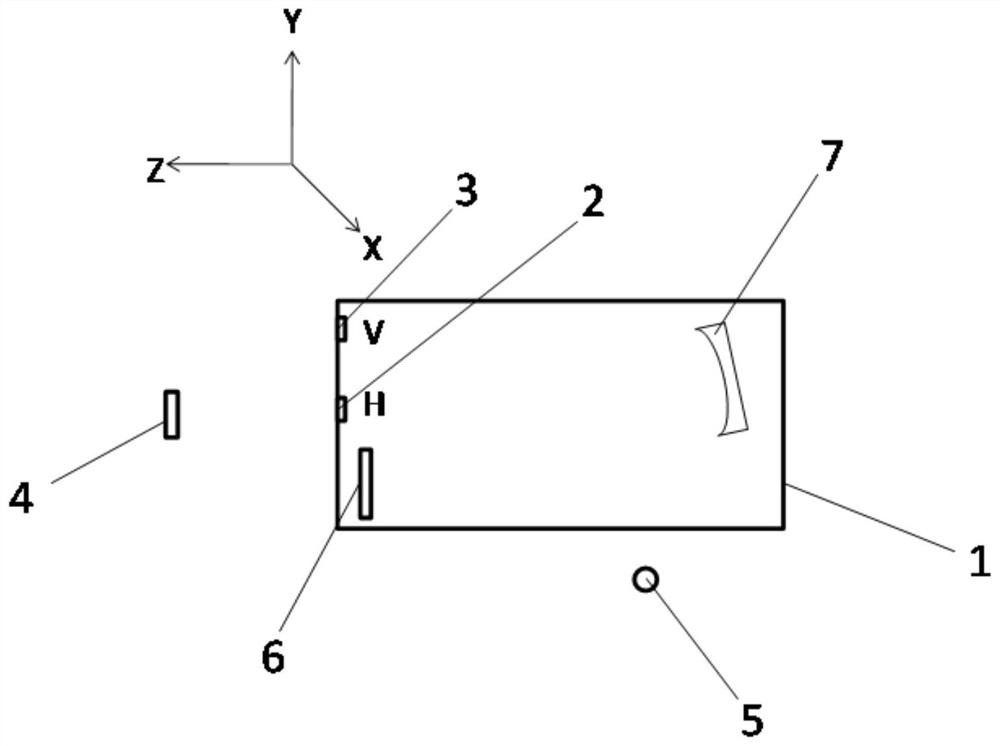

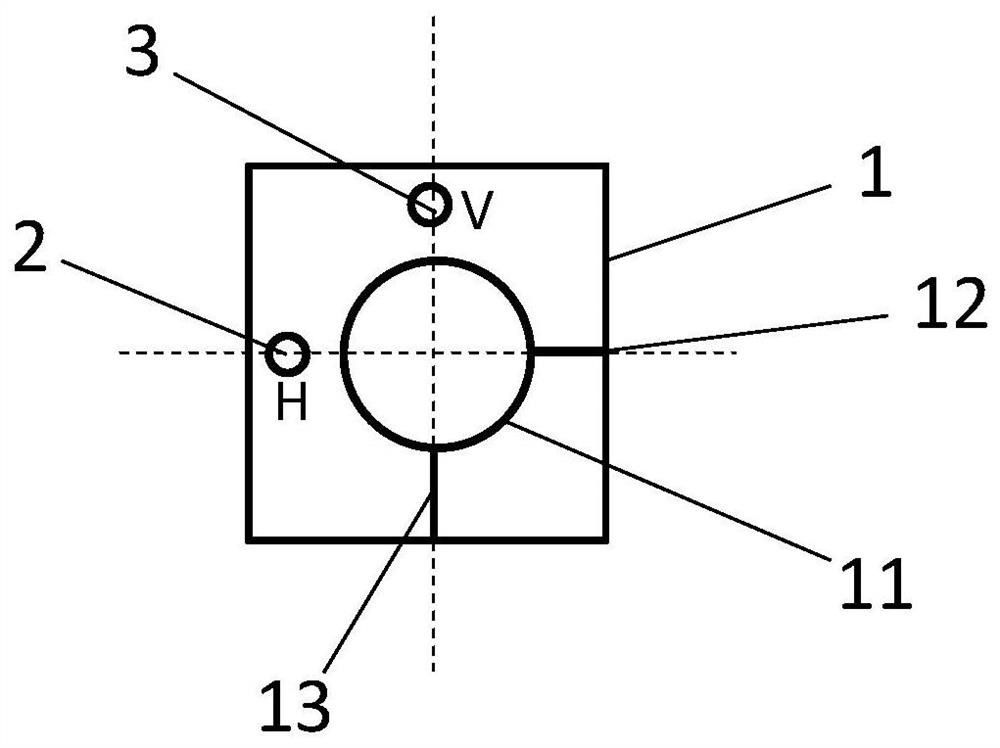

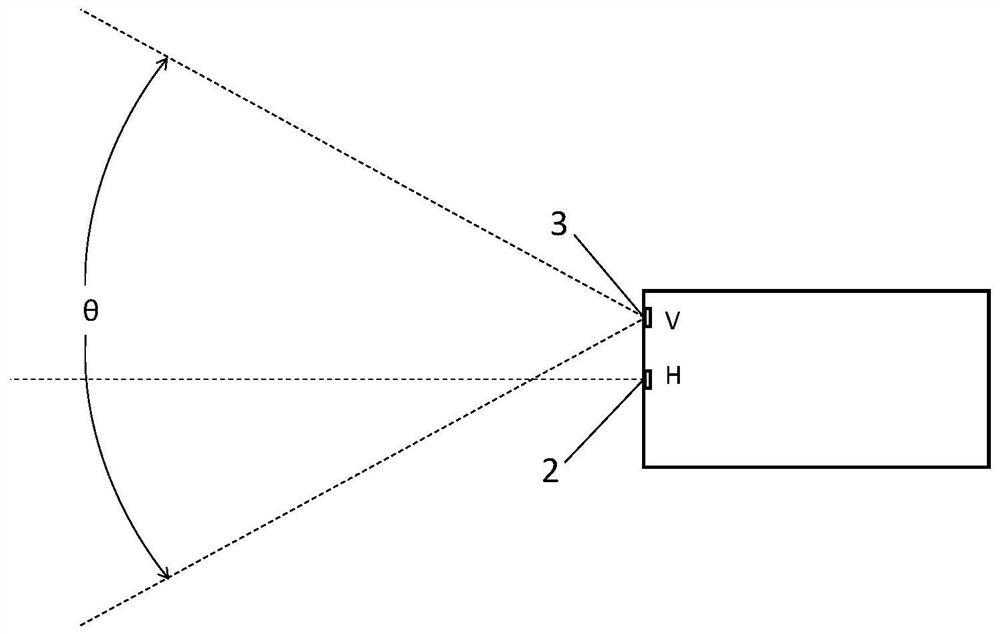

[0056] In the stray light test provided by the present invention, the optical axis of the collimator and the optical axis of the optical mechanical system are aligned, such as Figures 1 to 6 As shown, it includes structural frame 1, horizontal line laser (indicated by H in the figure, the outgoing horizontal laser line is consistent with the X direction) 2, vertical line laser (indicated by V in the figure, the outgoing vertical laser line is consistent with the Y direction) 3 , a receiving screen 4, and an interferometer 5, a plane folding mirror 6 and a parabolic mirror 7 arranged in sequence along the optical path; the plane folding mirror 6 and the parabolic mirror 7 form a collimator; the collimator is arranged on a structural frame 1; the interferometer 5 is arranged at the focal point of the collimator; the exit end face of the structural frame 1 is provided with an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com