Preparation method and application of lithium/lithiated metal oxide frame composite negative electrode

A composite structure and oxide technology, applied in the direction of negative electrodes, structural parts, active material electrodes, etc., can solve the problems of insufficient lithium dendrite inhibition and insignificant effects, achieve uniform lithium flux, low price, and avoid safety The effect of the accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

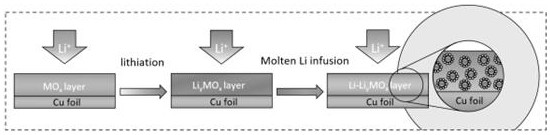

[0025] The present embodiment provides a method for preparing a fast ion transport type lithium / lithene metal oxide frame composite structure negative electrode for lithium secondary battery, the specific steps of the method are as follows:

[0026] (1) Will MnO 2 The powder, conductive carbon and PVDF are mixed according to 7:2:1, magnetically stirred for 12h, so that it is mixed evenly, and the mixed slurry is evenly coated on the surface of the copper foil with a scraper, and then transferred to a vacuum oven, 60 ° C, 12h, vacuum drying pole pieces.

[0027] (2) Take the lithium sheet as the negative electrode and the pole piece prepared in step (1) as the counter electrode at 0.5 mA g -1 The current density is constant current discharge, and the cutoff voltage is 1.5V, and Li is obtained y MnO 2 Electrode frame, 0.5≤y≤0.75.

[0028] (3) The Li obtained in step (2). y MnO 2 Electrode frame with molten lithium (Li y MnO 2 : Li = 1: 2) at 300 °C composite, the molten lithium is...

Embodiment 2

[0032] The present embodiment provides a method for preparing a fast ion transport type lithium / lithene metal oxide frame composite structure negative electrode for lithium secondary battery, the specific steps of the method are as follows:

[0033] (1) Move MoO 2 The powder, conductive carbon and PVDF are mixed according to 7:2:1, magnetically stirred for 24h, so that it is mixed evenly, and the mixed slurry is evenly coated on the surface of the copper foil with a scraper, and then transferred to a vacuum oven, 80 °C, 12h, vacuum drying pole pieces.

[0034] (2) Take the lithium sheet as the negative electrode and the pole piece prepared in step (1) as the counter electrode at 0.5 mA g -1 The current density is constant current discharge, and the cutoff voltage is 1.5V, and Li is obtained y TiO 2 Electrode frame, 0.5≤y≤0.75.

[0035] (3) The Li obtained in step (2). y TiO 2 Electrode frame with molten lithium (Li y TiO 2 : Li = 1: 2) at 300 °C composite, the molten lithium is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com