Subdivision motor driving circuit for realizing photometer grating direct drive

A motor drive circuit and motor driver technology, applied in the direction of connecting with control/drive circuits, etc., can solve problems such as troublesome installation and debugging, and achieve the effects of simple assembly and debugging, improved instrument performance, and fast speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, structure and working process of the present invention will be further described.

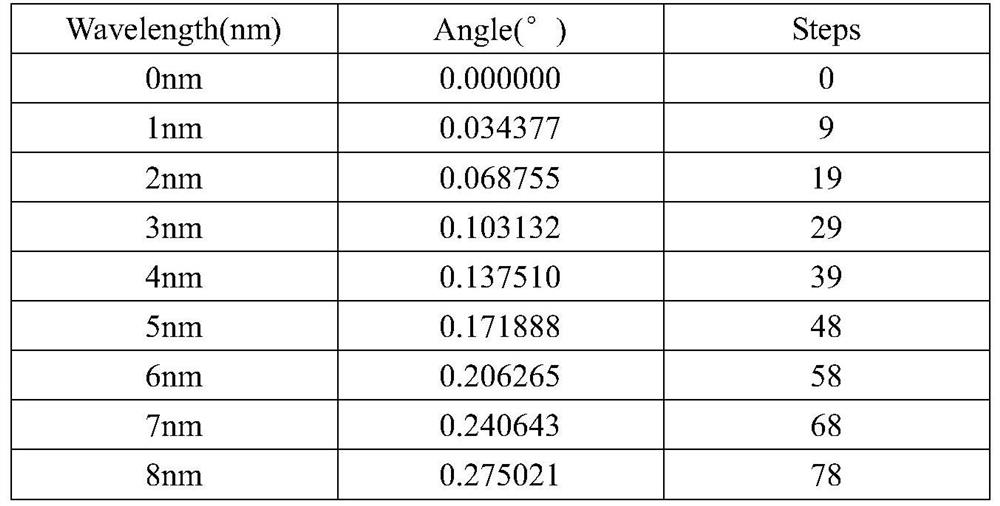

[0018] The main purpose of the development of this subdivision drive circuit is to simplify the structural components of the grating drive device of the monochromator of the spectrophotometer, reduce the stray light of the monochromator, increase the drive speed of the grating, and thus improve the overall performance of the instrument.

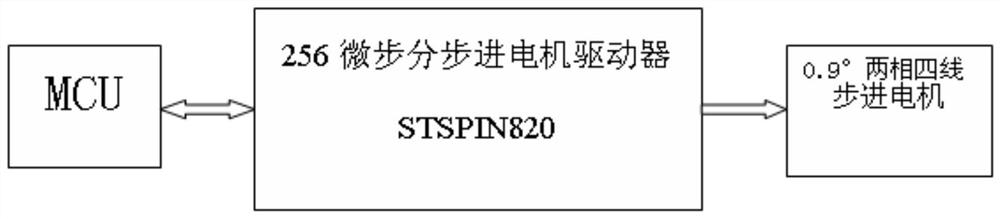

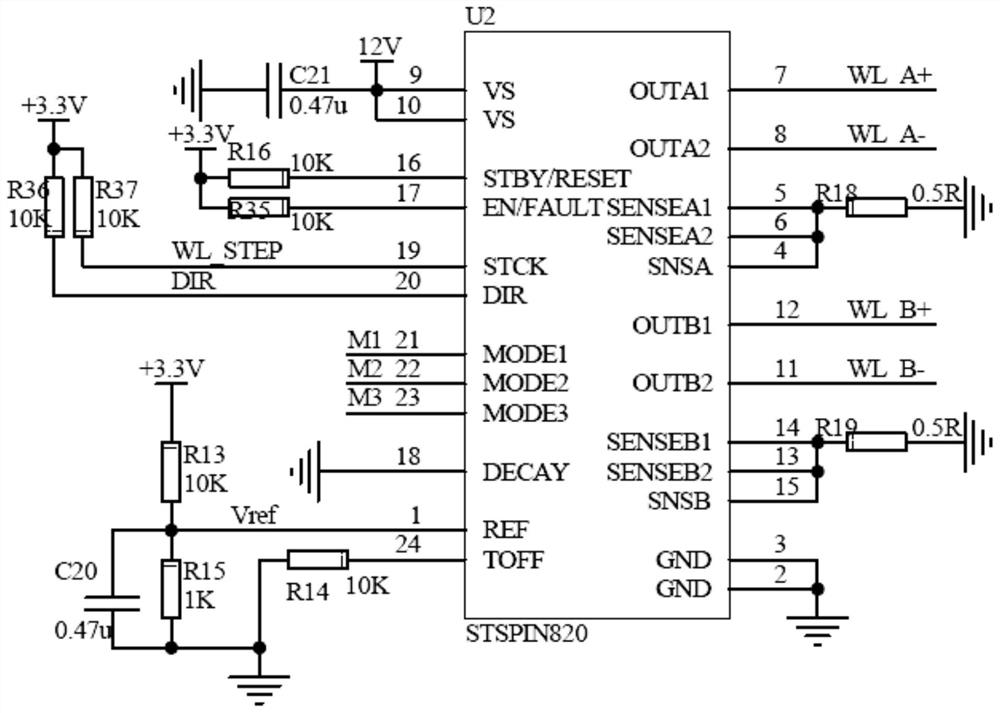

[0019] A subdivision motor drive circuit that realizes photometer grating direct drive, including a micro-step sub-step motor driver, the micro-step sub-step motor driver has a working mode configuration port, a bidirectional control port connected to an MCU, and a stepper motor driver. The output port connected to the motor; the bidirectional control port includes rotation direction control, rotation step setting, working state control, and micro-step resolution setting port; wherein, the rotation step set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com