Embedded degradable film direct-seeding system for crop direct-seeding and application

An embedded and degradable film technology, applied in the agricultural field, can solve the problems of unable to prevent the growth of weeds, not easy to degrade, easy to lodging, etc., to achieve the effects of shortening the growth cycle, avoiding pollution, and liberating labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

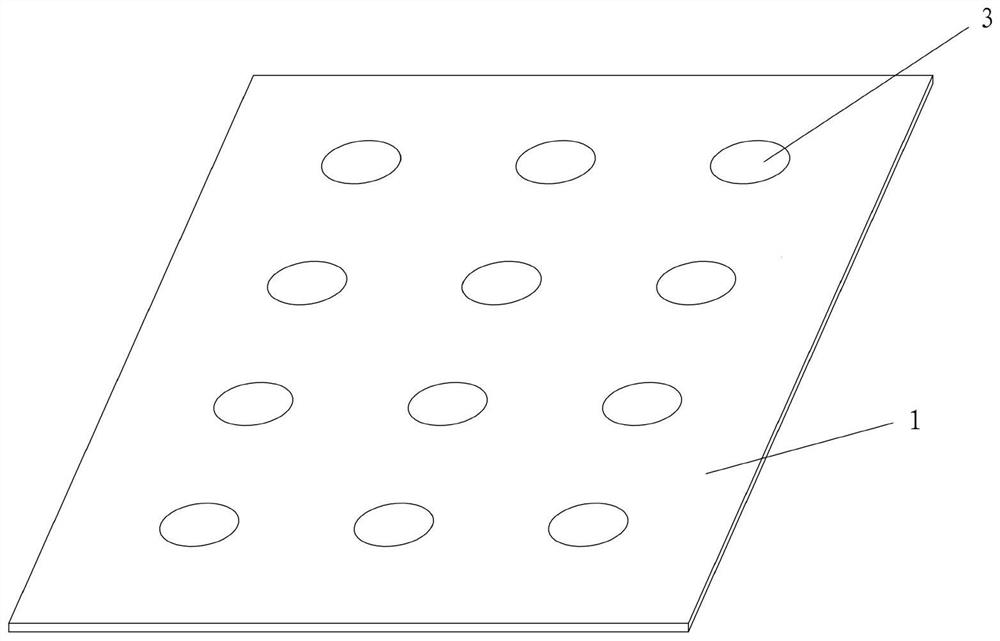

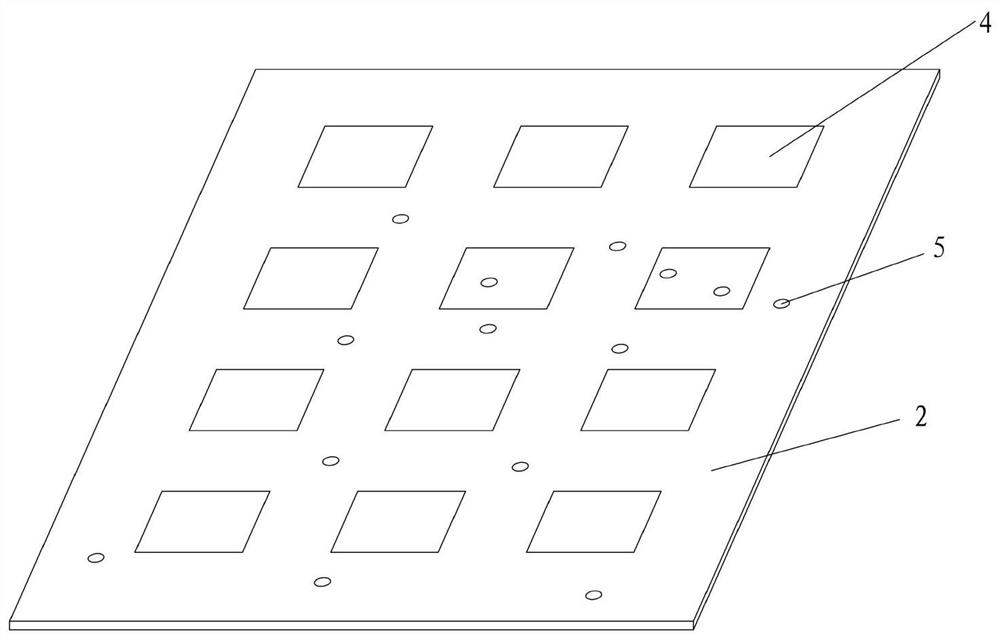

[0036] An embedded degradable film direct seeding system for direct seeding of crops, comprising: a degradable bottom film layer 1 and a degradable cover film layer 2, the degradable cover film layer 2 covers the top of the degradable bottom film layer 1; the seeds are glued and arranged The seed adhesive area 3 on the upper surface of the degradable base film layer 1; the degradable cover film layer 2 is provided with a degradable strip film 4 corresponding to the glued seed position of the degradable base film layer;

[0037] The degradable bottom film layer 1, the degradable cover film layer 2 and the degradable strip sheet film 4 include the following raw materials in parts by weight: starch 50g, polyvinyl alcohol 15g, dioctyl phthalate 5g, chitosan 15g, Carrageenan solution 20g and calcium silicate 3g.

[0038] The degradable bottom film layer 1, the degradable cover film layer 2 and the degradable strip film 4 are all colorless.

[0039] To further optimize the technica...

Embodiment 2

[0047] An embedded degradable film direct seeding system for direct seeding of crops, comprising: a degradable bottom film layer 1 and a degradable cover film layer 2, the degradable cover film layer 2 covers the top of the degradable bottom film layer 1; the seeds are glued and arranged The seed adhesive area 3 on the upper surface of the degradable base film layer 1; the degradable cover film layer 2 is provided with a degradable strip film 4 corresponding to the glued seed position of the degradable base film layer;

[0048] The degradable bottom film layer 1 is black, and the degradable cover film layer 2 and the degradable strip film 4 are colorless.

[0049] The degradable bottom film layer 1 includes the following raw materials in parts by weight: 40g of starch, 40 parts of black masterbatch, 15g of polyvinyl alcohol, 3g of dioctyl phthalate, 15g of chitosan, 10g of carrageenan solution and 3g of calcium silicate ;

[0050] The degradable cover film layer 2 and the deg...

Embodiment 3

[0063] An embedded degradable film direct seeding system for direct seeding of crops, comprising: a degradable bottom film layer 1 and a degradable cover film layer 2, the degradable cover film layer 2 covers the top of the degradable bottom film layer 1; the seeds are glued and arranged The seed adhesive area 3 on the upper surface of the degradable base film layer 1; the degradable cover film layer 2 is provided with a degradable strip film 4 corresponding to the glued seed position of the degradable base film layer;

[0064] The degradable bottom film layer 1 is black, and the degradable cover film layer 2 and the degradable strip film 4 are colorless.

[0065] The degradable bottom film layer 1 includes the following raw materials in parts by weight: 40g of starch, 50 parts of black masterbatch, 15g of polyvinyl alcohol, 3g of dioctyl phthalate, 15g of chitosan, 10g of carrageenan solution and 3g of calcium silicate ;

[0066] The degradable cover film layer 2 and the deg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com