Plastic film cleaning and winding apparatus for crab breeding pond

A technology of plastic film and retractable device, which is applied in the field of breeding, can solve the problems of inconvenient operation and management, time-consuming installation, and poor wind and snow resistance, so as to save human resources, purchase equipment at a low cost, and prolong the service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

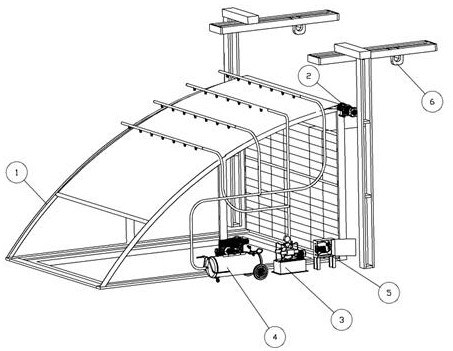

[0039] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 Shown a kind of pond that raises crabs uses plastic film to clean the retracting device. The main frame part 1 is placed on the ground, and is also an installation platform for the film retracting device 2, the cleaning film device 3, the drying device 4, the automatic control device 5, and the cantilever suspension device 6.

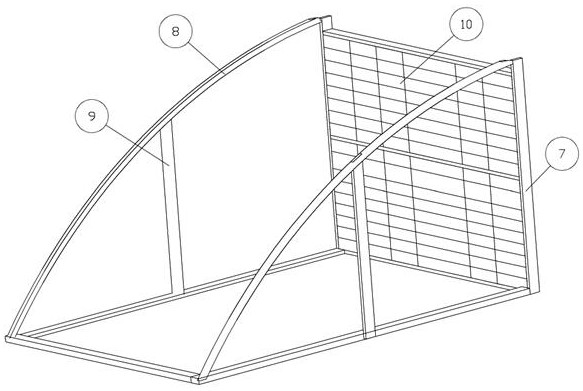

[0040] The specific structure of main frame part 1 is as follows figure 2As shown, the unwinding device column 7 is fixedly installed on the film lifting guide rail 8 with grooves, the guide rail support column 9 is fixedly installed on the film lifting guide rail 8 with grooves, and the brick wall 10 is fixedly installed on the end of the film lifting guide rail 8 with grooves , the film lifting guide rail 57 is fixedly installed on the grooved film lifting guide rail 8, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com