High-concealment sunscreen pressed powder for repairing and preparation method of high-concealment sunscreen pressed powder

A technology of concealer and powder, which is applied in the field of high-concealer sunscreen powder for repair and its preparation. It can solve the problems of not belonging to the skin care series, the decrease of skin moisture content, and the lack of protection, etc., to achieve good adhesion and fineness. Reduce makeup loss, moisturizing and delicate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

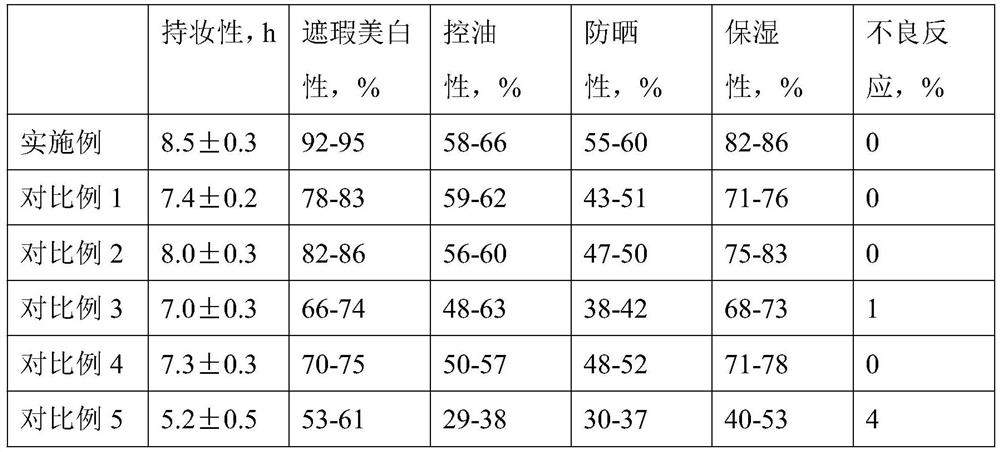

Examples

Embodiment 1

[0024] A high-concealment sunscreen powder cake for repairing, comprising the following raw materials in parts by mass: 50 parts of talcum powder, 8 parts of plant powder, 4 parts of calamine powder, 6 parts of titanium dioxide, 2 parts of bone collagen, 0.4 part of eriodictyol, bamboo Leaf extract 2 parts, hydrogenated palm oil 2 parts, mineral oil 2 parts, isopropyl palmitate 1 part, lauroyl lysine 1 part, phenoxyethanol 0.3%, hydroxypropyl cellulose 3 parts, coloring matter 20 1.5 parts, 1.5 parts of spices.

[0025] Wherein, the solid components in the raw materials are all pulverized through a 300-mesh sieve.

[0026] The plant powder is a composition of vine, honeysuckle and mulberry leaves with a mass ratio of 1:0.5:0.5.

[0027] The coloring material is a composition of fucoxanthin, iron oxide and mica, wherein mica accounts for 78 wt%, and fucoxanthin accounts for 13 wt%.

[0028] The fragrance is palmarosa essential oil compounded with rosewood essential oil, of wh...

Embodiment 2

[0036] A high-concealment sunscreen powder for repairing, comprising the following raw materials in parts by mass: 45 parts of talcum powder, 8 parts of plant powder, 5 parts of calamine powder, 5 parts of titanium dioxide, 4 parts of bone collagen, 0.4 part of eriodictyol, bamboo 1.5 parts of leaf extract, 2 parts of hydrogenated palm oil, 1 part of mineral oil, 1.5 parts of isopropyl palmitate, 1 part of lauroyl lysine, 0.2% of phenoxyethanol, 4 parts of hydroxypropyl cellulose, 20 parts of coloring matter 1 part, 1 part spice.

[0037] Wherein, the solid components in the raw materials are all pulverized through a 300-mesh sieve.

[0038] The plant powder is a composition of vine, honeysuckle and mulberry leaves with a mass ratio of 1:0.5:0.5.

[0039] The coloring material is a combination of fucoxanthin, iron oxide and mica, wherein the mica accounts for 75 wt%, and the fucoxanthin accounts for 12 wt%.

[0040] The fragrance is palmarosa essential oil compounded with ro...

Embodiment 3

[0043] A high-concealer sunscreen powder for repairing, comprising the following raw materials in parts by mass: 35 parts of talcum powder, 11 parts of plant powder, 5 parts of calamine powder, 8 parts of titanium dioxide, 4 parts of bone collagen, 0.3 part of eriodictyol, bamboo 3 parts of leaf extract, 2.5 parts of hydrogenated palm oil, 2 parts of mineral oil, 1.5 parts of isopropyl palmitate, 1.5 parts of lauroyl lysine, 0.1% of phenoxyethanol, 4 parts of hydroxypropyl cellulose, 25 parts of coloring matter 1.5 parts, 1.5 parts of spices.

[0044] Wherein, the solid components in the raw materials are all pulverized through a 300-mesh sieve.

[0045] The plant powder is a composition of mama vine, honeysuckle and mulberry leaves with a mass ratio of 1:0.5:0.1.

[0046] The coloring material is a composition of fucoxanthin, iron oxide and mica, wherein mica accounts for 74 wt%, and fucoxanthin accounts for 13 wt%.

[0047] The spice is palmarosa essential oil compounded w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com