Corn harvesting and returning machine shell welding system and method

A welding system and harvesting technology, applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., to achieve the effect of ensuring mobility, improving welding efficiency, fast and effective fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

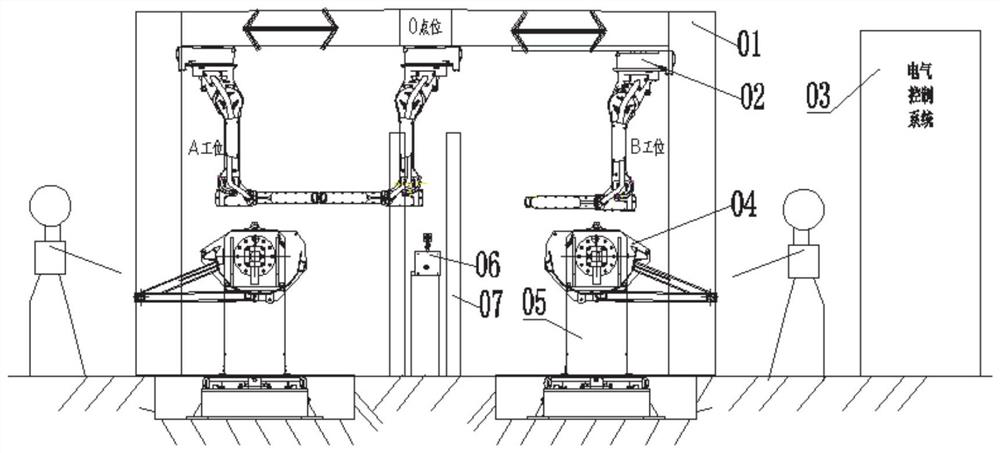

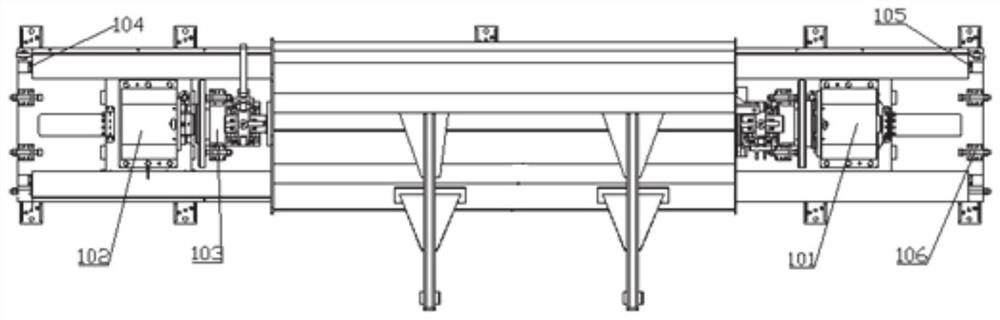

[0053] Such as Figure 1-Figure 8 As shown, Embodiment 1 of the present disclosure provides a robot welding system for the casing of the corn harvester returning to the field, including two sets of six-axis robots 02, two sets of welding robot systems 11, a set of double longitudinal beam gantry robot suspension devices 01, Two sets of single-axis head and tail frame adjustable positioner system 05, two sets of tooling fixtures, electrical control system 03, two sets of lifting anti-arc devices 07, and a set of gun cleaning and wire cutting device 06;

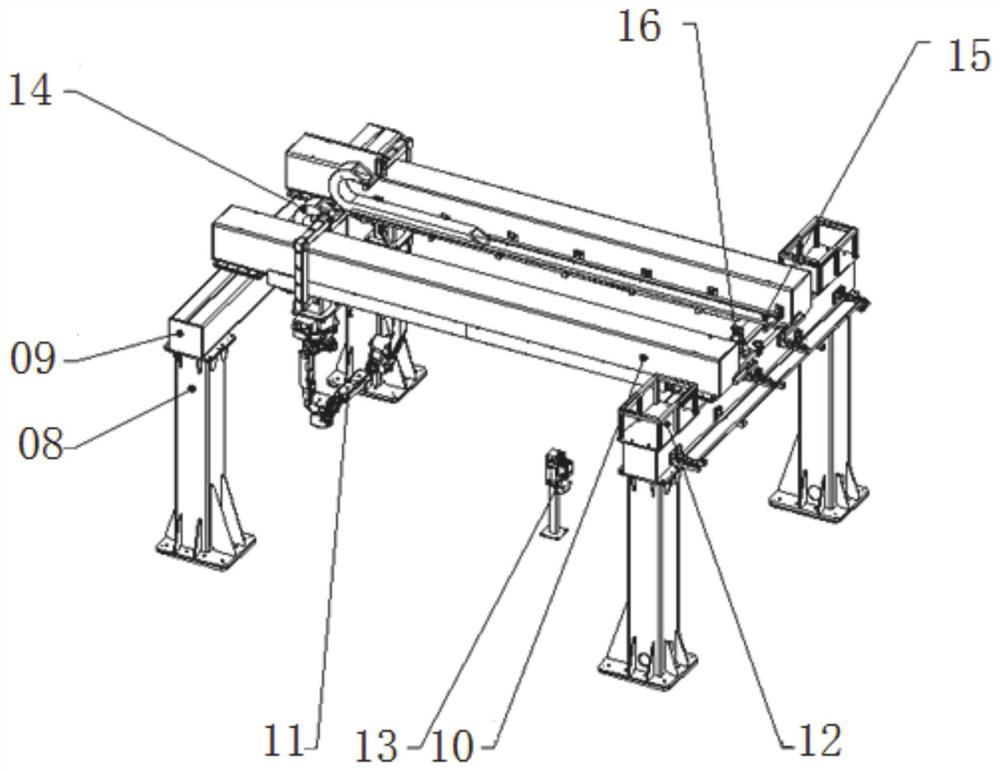

[0054] The double-longitudinal gantry robot suspension device 01 includes two sets of longitudinal beams 10 above the gantry, which are installed on two gantry crossbeams 09, and the crossbeams are installed on four gantry columns 08.

[0055] The lower surface of the longitudinal beam 10 is provided with slide rails, sliders and racks, the robot moves on the longitudinal beam 10 through servo motors and gear drives, and the robo...

Embodiment 2

[0079] Embodiment 2 of the present disclosure provides a working method of a welding system for a corn harvesting and returning machine housing. Using the welding system described in Embodiment 1 of the present disclosure, taking two sets of robots as an example, the following steps are included:

[0080] When the system is started, the robot is at the 0 o'clock position, and the worker is loading the piece at station A;

[0081] Start the system, and the two sets of robots move from 0 to station A at the same time to perform automatic welding operations. At this time, workers are loading parts at station B;

[0082] After the operation of station A is completed, the two sets of robots move to the 0 point at the same time. After waiting for the start of station B, the two sets of robots move to station B at the same time for automatic welding operations. Blank parts, so cycle.

[0083] The two robots use the signal interlock function to prevent collisions when the robots move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com