Method for improving electromagnetic shielding performance of MXene-based composite fabric material

A technology of composite fabrics and fabric materials, applied in chemical instruments and methods, light-resistant fibers, textiles and papermaking, etc., can solve the problems of low absorption and shielding energy, complex processes, etc., achieve good flexibility and shielding performance, and reduce surface reflections , the effect of reducing absorption loss and reflection loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Utilize acetone to carry out ultrasonic pretreatment to polypropylene non-woven fabric, remove the oil stain and impurity on fabric surface, clean and dry with distilled water;

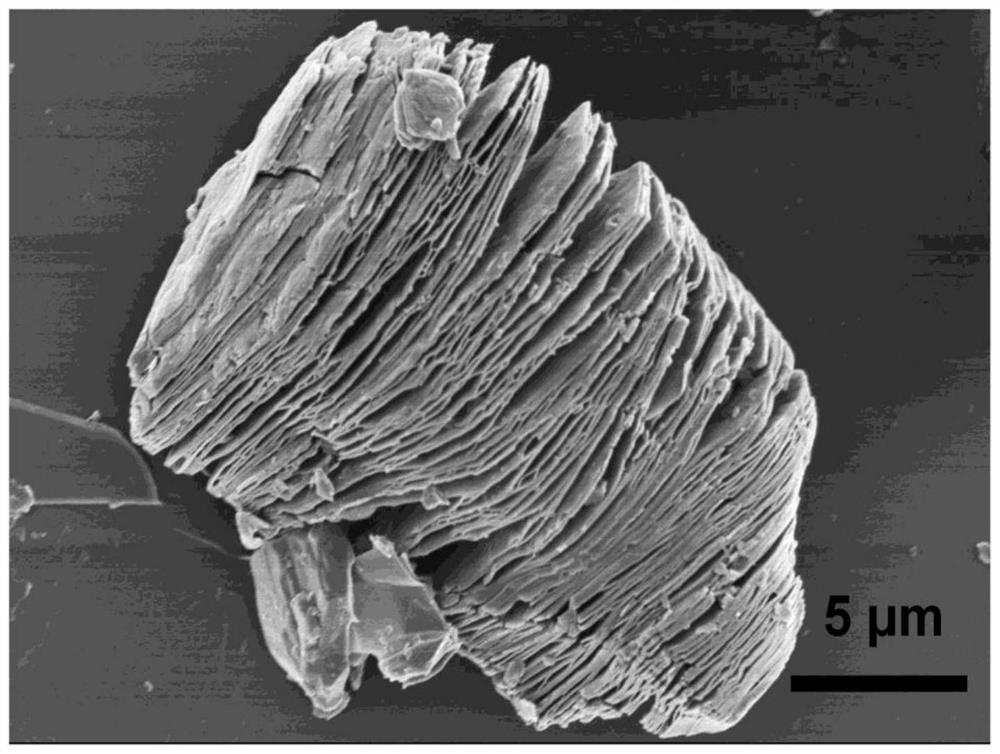

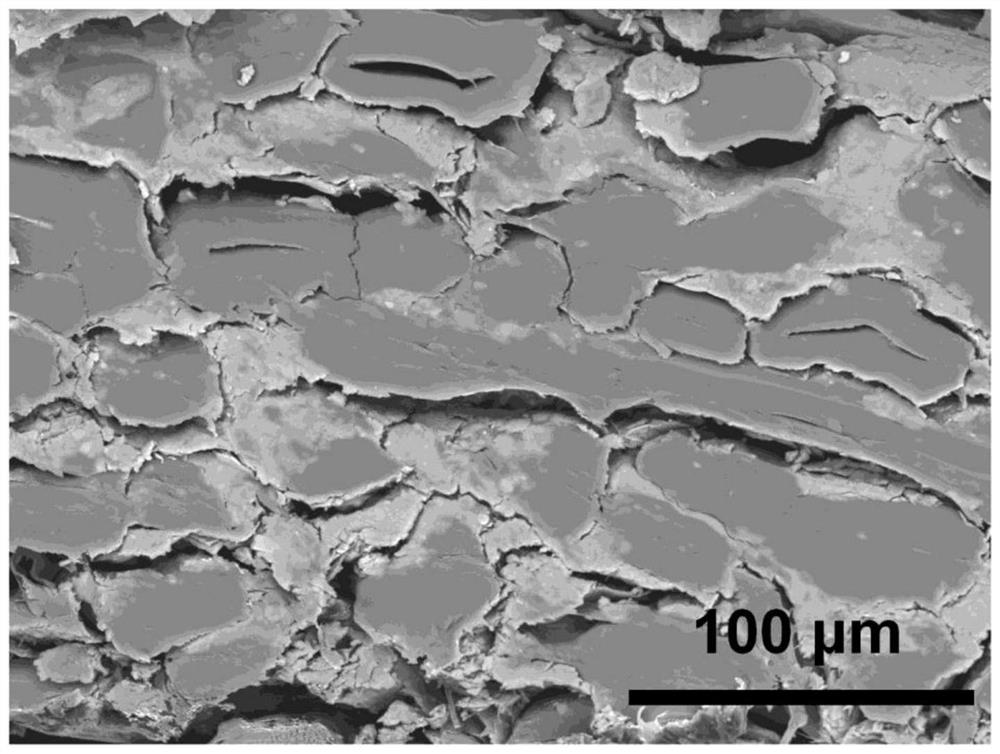

[0043] (2) Dip-coat 15 mg / ml MXene aqueous dispersion on the pretreated fabric and vacuum dry, the vacuum drying time is 5-10 hours, and the drying temperature is 45-60°C to obtain MXene-coated polypropylene Non-woven fabric; wherein, the content of MXene on the fabric after drying is 0.06g / cm 2 ;

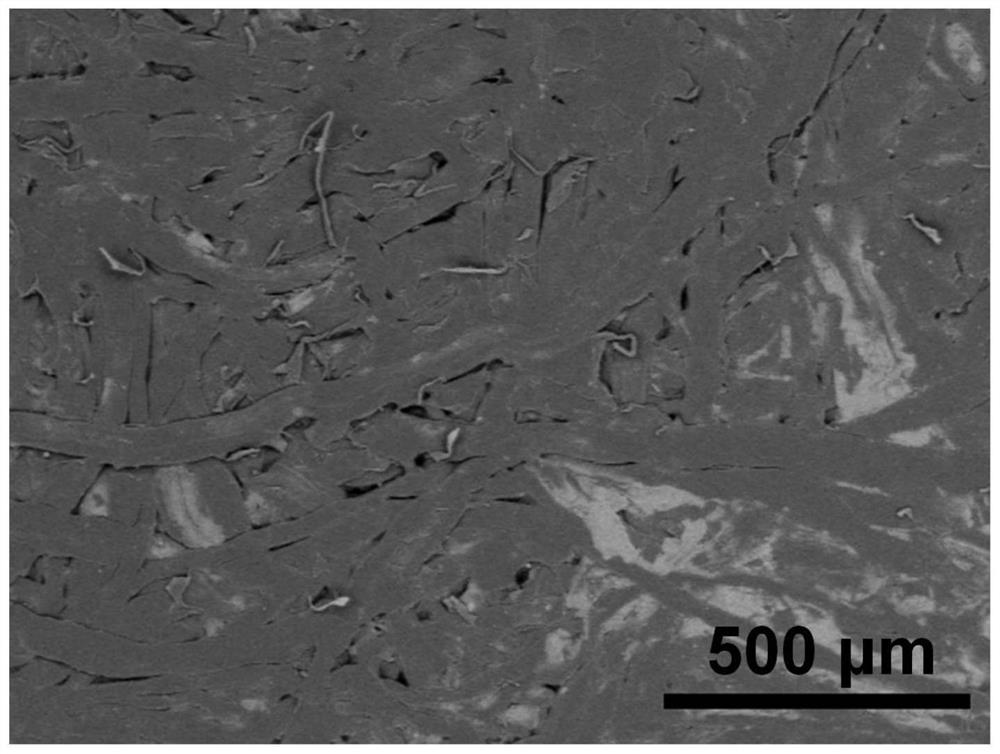

[0044] (3) The four-layer MXene-coated polypropylene nonwoven fabric prepared in step (2) was stacked neatly, and then hot-pressed and laminated at a temperature of 160-200 ° C to obtain a composite fabric material based on MXene.

[0045] Test the electromagnetic shielding performance of the MXene-based composite fabric material prepared in this embodiment, such as Figure 4-5 As shown, its shielding performance can reach 42 decibels, of which the absorption shielding performance can reach 32...

Embodiment 2

[0047] Prepare the composite fabric material based on MXene according to the method of Example 1, the difference is that in step (2), the MXene aqueous dispersion of 30 mg / ml is used to dip-coat on the pretreated fabric, after drying, the fabric The content of MXene is 0.14g / cm 2 .

[0048] Test the electromagnetic shielding performance of the MXene-based composite fabric material prepared in this embodiment, such as Figure 4-5 As shown, its shielding performance can reach 53 decibels, of which the absorption and shielding performance can reach 41 decibels.

Embodiment 3

[0050] Prepare the composite fabric material based on MXene according to the method of Example 1, the difference is that, in step (2), the MXene water dispersion of 45 mg / ml is used to dip-coat on the pretreated fabric, after drying, the fabric The content of MXene is 0.25g / cm 2 .

[0051] Test the electromagnetic shielding performance of the MXene-based composite fabric material prepared in this embodiment, such as Figure 4-5 As shown, its shielding performance can reach 66 decibels, of which the absorption shielding performance can reach 53 decibels.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com