Method for enhancing compactness of BaMnO4 material

A technology of compactness and material structure, applied in chemical instruments and methods, fluid pressure measurement using optical methods, manganate/permanganate, etc., can solve the problems of dense structure of BaMnO4 materials that have not been seen, and achieve Simple operation, reduced unit cell volume, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

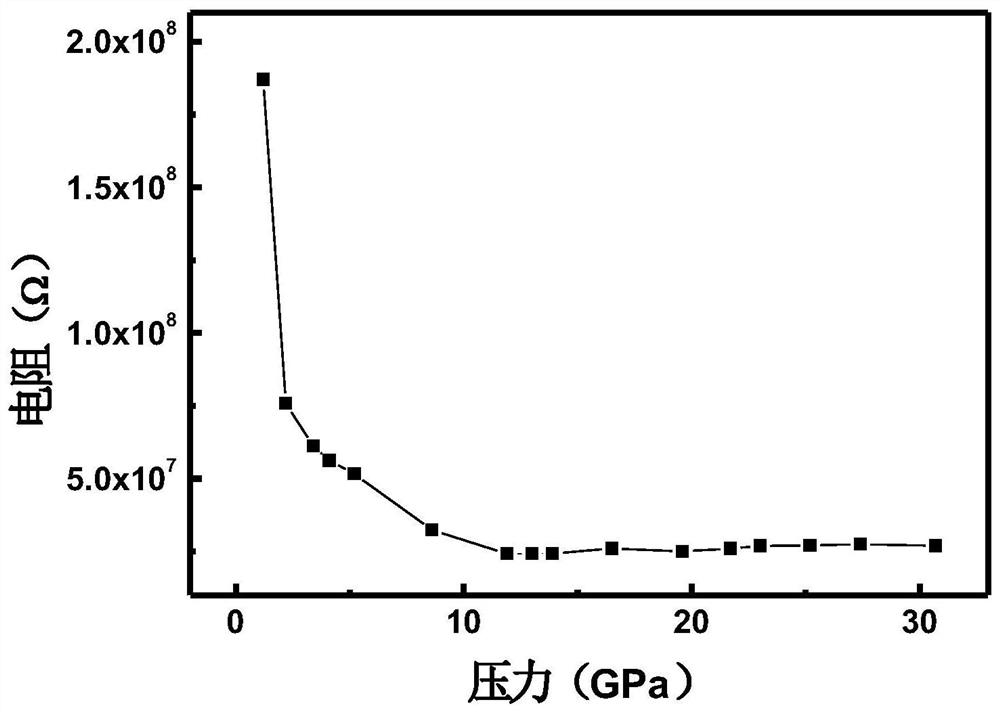

[0017] Level and center the diamond anvil device, select T301 steel sheet pre-pressed as the gasket, punch the gasket and insulate the gasket, use cubic BN as the insulating powder, and add the insulating powder to the gasket. Press, and then punch a hole in the pressed insulating powder to make a sample cavity, arrange two electrodes on the diamond anvil, and BaMnO 4 The powder was thoroughly ground for 2 minutes and the sample was added in a diamond-anvil-sealed sample chamber. The ruby fluorescence peak is used as the calibration object of the pressure. The pressure is applied to the inside of the sample chamber of the diamond-anvil device, and the in-situ high-voltage impedance spectroscopy test is carried out.

[0018] Change the internal pressure of the sample cavity of the diamond anvil device in the range of 1.2-30.7GPa, and take 1.2, 2.2, 3.4, 4.1, 5.2GPa, 8.6GPa, 11.9GPa, 13.0, 13.9GPa, 16.5GPa, 19.6GPa in this pressure range GPa, 21.7, 23.0GPa, 25.2GPa, 27.4GPa,...

Embodiment 2

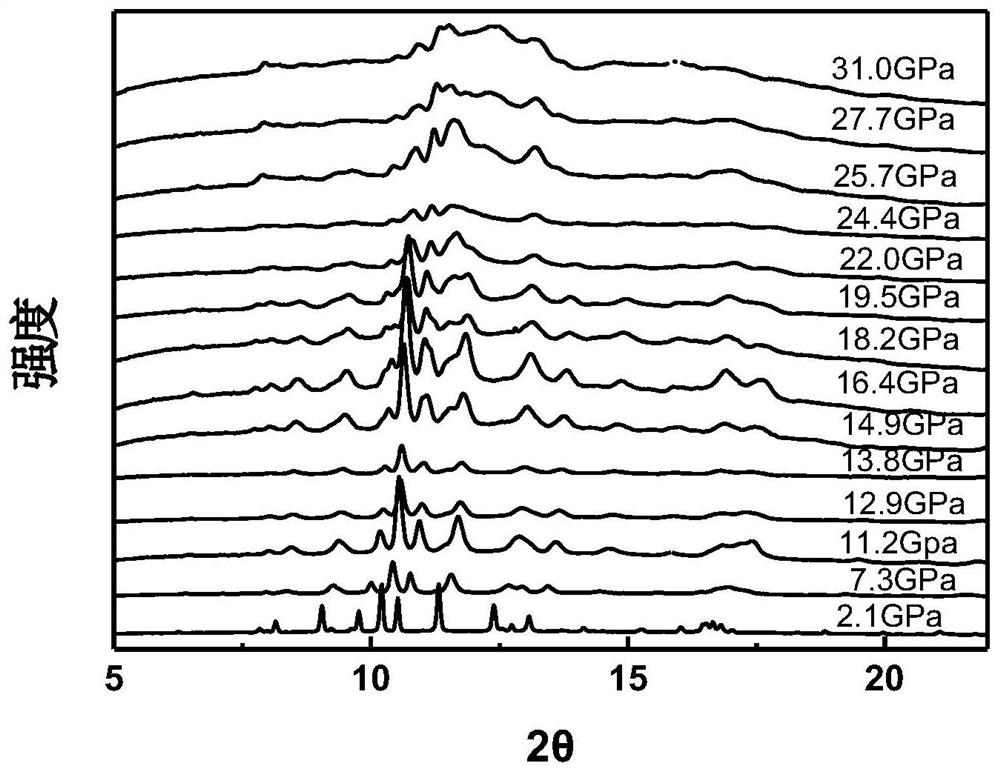

[0020] Firstly, the diamond counter-anvil device is adjusted, and the BaMnO 4 The sample is placed in the high-pressure device. The diamond anvil surface is 300um. T301 steel sheet is selected as the gasket material with a thickness of 250um. Silicon oil is used as the pressure transmission medium. The ruby fluorescence peak is used as the calibration object of the pressure. on the synchrotron radiation source bench. The pressure is applied to the inside of the sample chamber of the diamond-anvil device, and the high-pressure synchrotron radiation diffraction experiment test is carried out.

[0021] Change the internal pressure of the sample cavity of the diamond-to-anvil device in the range of 2.1-31.0GPa, and take 2.1, 7.3, 11.2, 12.9, 13.8, 14.9, 16.4, 18.2, 19.5, 22.0, 24.4, 25.7, 27.7, 31.0GPa isopressure point test high pressure synchrotron radiation diffraction experiment, analysis of BaMnO 4 The experimental data of the various diffraction peaks and diffraction an...

Embodiment 3

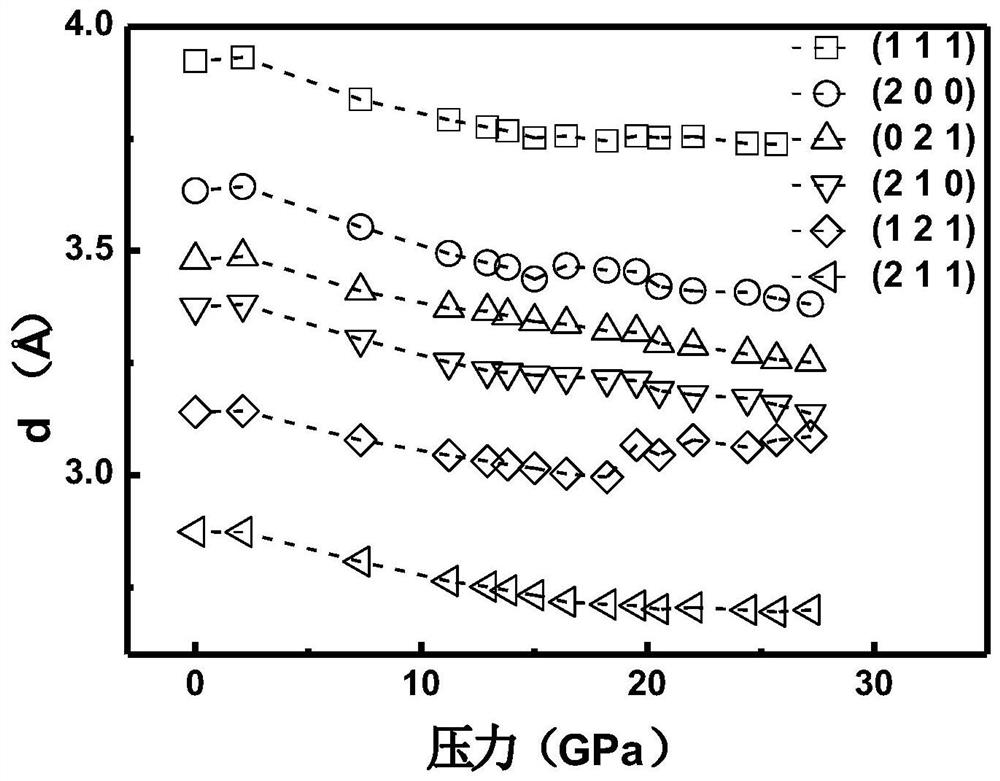

[0023] The BaMnO in embodiment 1 4 On each resistance data of the 16 pressure points obtained above, the internal pressure of the sample cavity of the diamond-to-anvil device is used to calibrate BaMnO with Search match software. 4 The d value of each characteristic crystal plane index changes with the pressure. For the specific test results, see image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com