Sludge reduction method adopting combination of high-purity pure oxygen and microorganisms for treatment

A technology of microbial treatment and sludge reduction, applied in the direction of biological sludge treatment, etc., can solve problems such as secondary pollution, achieve the effect of small footprint, significant deodorization effect, and easy mobile installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

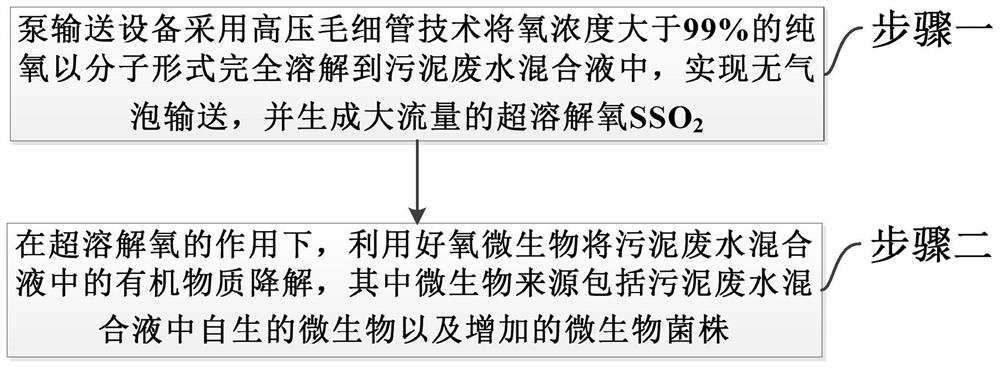

[0046] Such as figure 1 As shown, Embodiment 1 of the present invention provides a method for reducing sludge volume using high-purity pure oxygen combined with microbial treatment, the method comprising:

[0047] Step 1. The pump conveying equipment adopts high-pressure capillary technology to completely dissolve pure oxygen with an oxygen concentration greater than 99% into the sludge and wastewater mixture in molecular form, so as to realize air-bubble-free conveying and generate large-flow super-dissolved oxygen SSO 2 .

[0048] This step results in an oxygen transfer efficiency as high as 85-96%. Completely dissolve pure oxygen into water in the form of molecules to generate large flow of super-dissolved oxygen (SSO2), so that oxygen can reach an ultra-high concentration of 400mg / L or even higher in water, and can achieve bubble-free transmission and long-term retention.

[0049] For example: our chemical wastewater biochemical treatment plant produces about 10 tons of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com