Preparation method of E0-grade urea-formaldehyde adhesive

A technology of urea-formaldehyde glue and formaldehyde solution, applied in the direction of adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc., can solve problems such as affecting production capacity, avoid pollution, increase viscosity, and achieve good bonding performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

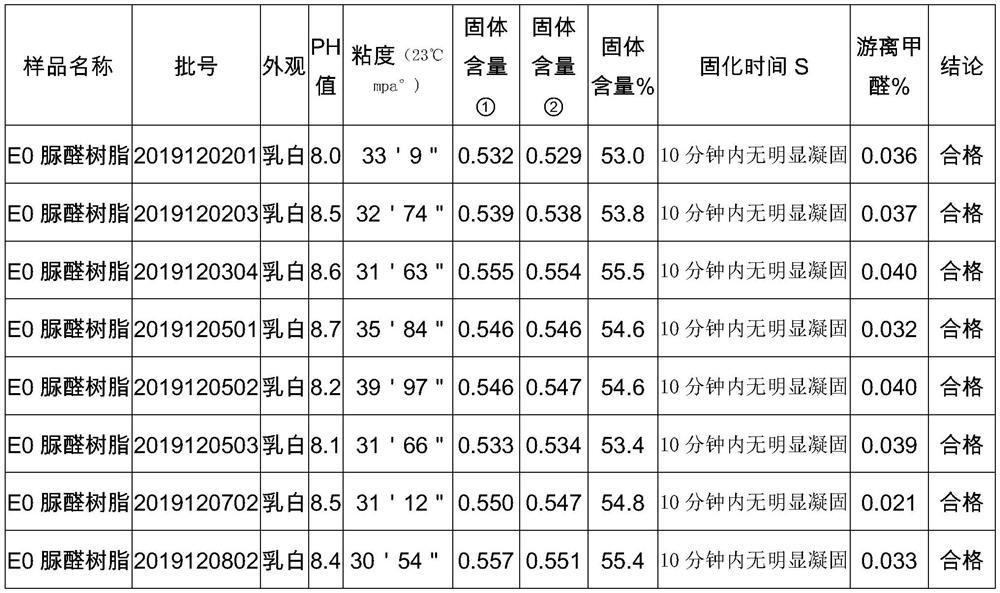

Examples

Embodiment 1

[0023] A preparation method of E0 grade urea-formaldehyde glue, comprising the following steps:

[0024] (1) Mixing and heating stage: first use a metering pump to put 37% formaldehyde solution into the reaction kettle, add sodium hydroxide solution to adjust the pH value between 7.0, then start stirring after adding polyvinyl alcohol and melamine, and react under normal pressure Introduce steam into the kettle jacket to raise the temperature to 55° C., and react for 40 minutes. In this step, the ratio of parts by weight of formaldehyde solution, polyvinyl alcohol and melamine is 57.6:1:1;

[0025] (2) Addition stage: add urea to the reaction kettle after mixing and heating up, then raise the temperature of the reaction kettle to 70°C through steam, stop adding steam, and wait for the temperature to rise to 82°C naturally, then cover the outer layer of the reaction kettle to keep warm Set, heat preservation reaction for 30 minutes, add urea and formaldehyde contained in interm...

Embodiment 2

[0032] A preparation method of E0 grade urea-formaldehyde glue, comprising the following steps:

[0033] (1) Mixing and heating stage: first use a metering pump to put 37% formaldehyde solution into the reaction kettle, add sodium hydroxide solution to adjust the pH value between 7.2, then start stirring after adding polyvinyl alcohol and melamine, and react under normal pressure Introduce steam into the kettle jacket to raise the temperature to 58° C., and react for 40 minutes. The ratio of formaldehyde solution, polyvinyl alcohol and melamine in parts by weight is 57.6:1:1 in this step;

[0034] (2) Addition stage: add urea to the reaction kettle after mixing and heating, then raise the temperature of the reaction kettle to 70°C by steam, stop adding steam, and wait for the temperature to rise naturally to 83°C, then cover the outer layer of the reaction kettle to keep warm Set, heat preservation reaction for 30 minutes, add urea and formaldehyde contained in intermediate A ...

Embodiment 3

[0041] A preparation method of E0 grade urea-formaldehyde glue, comprising the following steps:

[0042] (1) Mixing and heating stage: First, use a metering pump to pour 37% formaldehyde solution into the reaction kettle, add sodium hydroxide solution to adjust the pH value between 7.5, and then start stirring after adding polyvinyl alcohol and melamine, and react under normal pressure Pass steam into the still jacket to raise the temperature to 60° C., and react for 40 minutes. In this step, the ratio of formaldehyde solution, polyvinyl alcohol and melamine in parts by weight is 57.6:1:1;

[0043](2) Addition stage: add urea to the reaction kettle after mixing and heating, then raise the temperature of the reaction kettle to 70°C by steam, stop adding steam, wait for it to naturally heat up to 84°C, and keep warm on the outer layer of the reaction kettle Set, heat preservation reaction for 30min, add urea and formaldehyde contained in intermediate A with a molar ratio of ≤1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com